ATS offers a suite of advanced automation software designed to enhance manufacturing efficiency and productivity. Each solution addresses specific needs in various industries, from automotive and eMobility to consumer goods and renewables. By integrating these tools, manufacturers can access real-time monitoring, data that informs strategic decisions, and seamless automation, ultimately driving operational excellence and innovation.

Explore how ATS’s innovative software can transform manufacturing processes. From concurrent data collection to preventive maintenance and virtual reality (VR) training, these programs empower manufacturers to stay ahead in today’s competitive market and take the first step toward a smarter production environment.

Every automation project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Software Offerings

ATS Test Executive Suite

The Test Executive Suite is a robust platform that teams can quickly configure for various testing requirements, ensuring product parts meet customer standards. With over 1,500 installations, this fifth-generation software offers unparalleled flexibility and precision, allowing users to define test parameters and pass or fail criteria. It supports high sampling rates and integrates with manufacturing execution systems (MES) and supervisory control and data acquisition systems (SCADA). The platform’s data-driven design ensures a consistent user experience, making it a trusted choice across industries.

High-Reliability Nuclear Software

ATS delivers high-reliability software solutions that power some of the world’s most critical systems. Our integrated in-house offering can include software, electrical hardware, and tooling—all developed and supported internally. This means faster deployment, minimal learning curve, reduced integration risk, and a lower total cost of ownership through streamlined support and faster troubleshooting.

Illuminate™ Manufacturing Intelligence

Illuminate™ Manufacturing Intelligence is a comprehensive factory-floor management platform designed to optimize production efficiency. By collecting and analyzing real-time data from production systems, it provides operational visibility, enabling manufacturers to make informed decisions based on rapid insights. The platform helps identify and address issues promptly, reducing unplanned downtime. Illuminate™ also includes specialized add-on modules, such as energy consumption tracking and preventive maintenance, making it a versatile tool for leaders with sustainable assembly goals.

PA Facts

This cloud-based Industrial Internet of Things (IIoT) solution transforms complex data into actionable insights. Leveraging Microsoft Azure technology, the tool offers high security standards and can meet the specific needs of any industrial manufacturer. PA Facts integrates and contextualizes information from all factory sources to enhance manufacturing efficiency and quickly address system failures. This versatile platform supports the optimization of key performance indicators and value drivers, facilitating collaboration between stakeholders in production and operations.

RALPH Analytics

Reporting Analysis Line Production History (RALPH) Analytics is a high-level data collection and reporting tool that enables operators to access rapid production data and quickly identify trends using built-in dashboards. Remote data mining capabilities let users query historical information and create custom graphs. RALPH collects real-time line performance insights from any device on the floor and sends alerts when lines drift outside expected limits, saving teams hours of time. This user-friendly platform can also generate reports for specific operational and business needs.

SAMS Line Control

Sequenced Automation Manufacturing Solution (SAMS) is a flexible software that controls and verifies lines and build processes. It integrates build recipe data and script logic to determine the desired course of action, including prompts, feedback, direct instrumentation control, and interaction with the programmable logic controller (PLC). SAMS ensures a complete build history for product traceability and allows for updates without a programmer or PLC code adjustments. This platform is ideal for a 24/7 production environment, providing maximum reliability while maintaining flexibility for future programs, models, and product changes.

Smart Coach™

Reporting Analysis Line Production History (RALPH) Analytics is a high-level data collection and reporting tool that enables operators to access rapid production data and quickly identify trends using built-in dashboards. Remote data mining capabilities let users query historical information and create custom graphs. RALPH collects real-time line performance insights from any device on the floor and sends alerts when lines drift outside expected limits, saving teams hours of time. This user-friendly platform can also generate reports for specific operational and business needs.

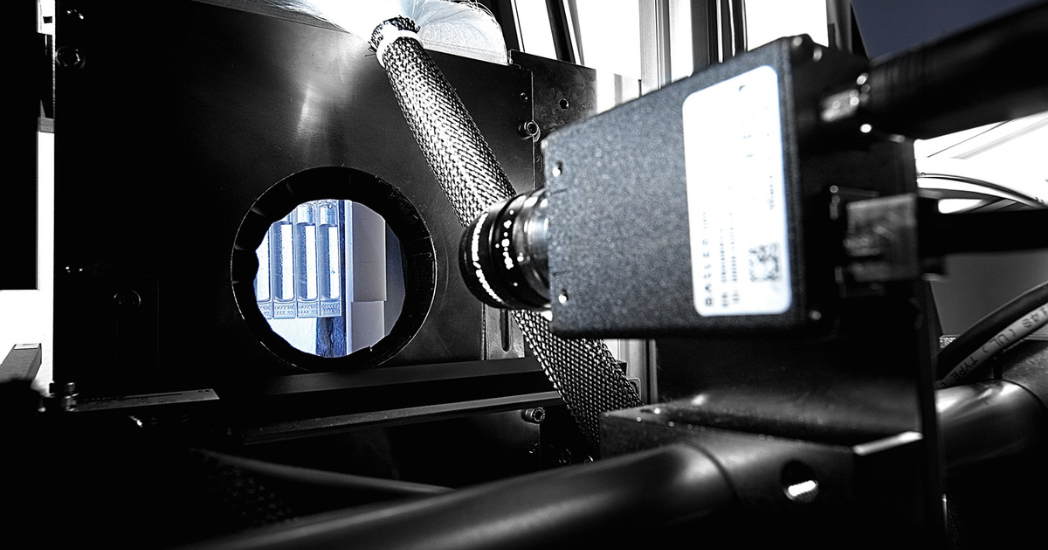

SmartVision™

This advanced automated vision system offers high-speed, high-accuracy inspection and measurement capabilities. It features a robust runtime software and hardware environment, without the need for an external development tool. The system includes a comprehensive, flexible toolkit and excellent industrial connectivity, making it suitable for various applications. The solution integrates seamlessly with other automation equipment, ensuring consistent and accurate evaluations. It supports multiple camera ports, 4K display, and passive cooling, making it a reliable choice for industries that require precise visual inspection.

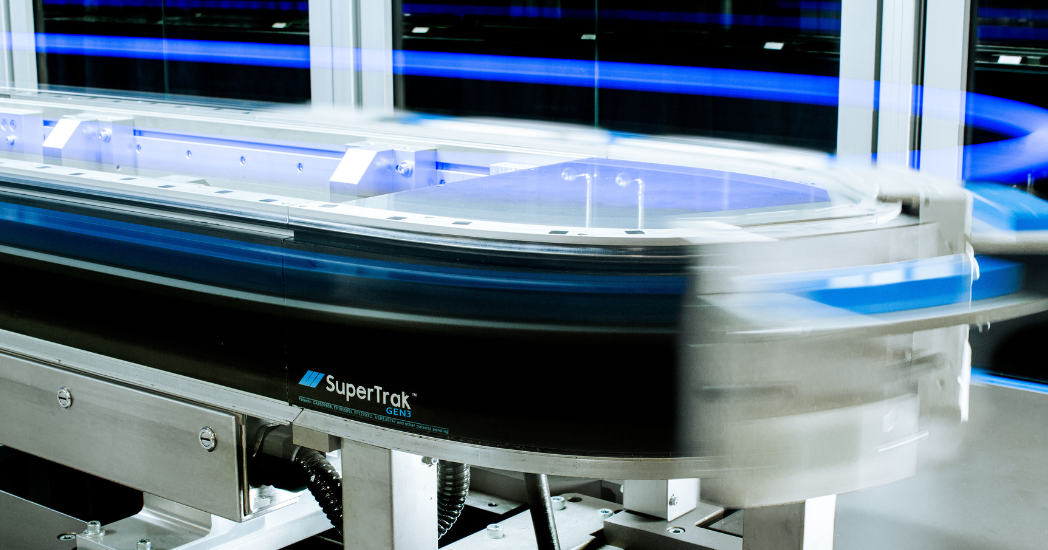

SuperTrak CONVEYANCE™

SuperTrak CONVEYANCE™ Platform is a modular linear motion system designed to enhance production by enabling faster cycle times and precise product handling. It integrates with existing automated assembly setups, providing fast, accurate material transport. A modular design allows for easy customization and scalability, ensuring each solution meets specific needs. SuperTrak is particularly useful in high-speed applications where precision and reliability are paramount, helping manufacturers streamline assembly and improve operational efficiency.

Symphoni™

Symphoni™ is a flexible automation software ideal for the fast-moving assembly of small parts. It leverages standardized, pre-validated building blocks to enable rapid deployment and scalability, from prototype to full production. Symphoni™ offers a competitive edge by providing high-speed automated assembly that can adapt to various manufacturing needs. It supports a range of applications, including consumer and industrial products, and helps manufacturers achieve higher efficiency and agility in their production processes.

UReality

UReality is a virtual reality (VR) training software suite optimizes training by creating fast, efficient, and interactive learning experiences. It allows companies to train employees in real-time, even when team members are in different locations. The user-friendly suite includes realistic, fully interactive environments that require no programming knowledge to build, share, and use. UReality improves learning retention by simulating real-life scenarios and provides a cost-effective option by reducing the time, travel, and expenses associated with traditional training methods.

XR-Hub

XR-Hub is a platform for hosting, managing, and streaming augmented reality (AR), VR training, and other applications to mobile devices, tablets, VR goggles, and desktops. This platform frees users from being tethered to large servers, allowing them to use applications on the shop floor and stream content from the cloud or in-house servers. XR-Hub redefines how users interact with digital environments, delivering a seamless, intuitive, and immersive experience.

YANOMALY Predictive Maintenance

YANOMALY is an industrial data analytics software that enhances machine performance monitoring and preventive maintenance. It uses artificial intelligence (AI) to monitor the condition of assets in real-time and identify unusual patterns and deviations from normal behavior. Key features include AI-powered anomaly detection, predictive models to forecast failures or product quality issues, and asset performance monitoring with detectors for common equipment like motors, pumps, and compressors.