Electric motors, or eMotors, are crucial components in electric vehicles (EVs). They convert electrical energy into mechanical energy to power the vehicle. Unlike traditional combustion engines, eMotors offer higher efficiency, zero emissions, and reduced maintenance requirements. They are integral to the EV powertrain, working in conjunction with other components to ensure smooth vehicle operation.

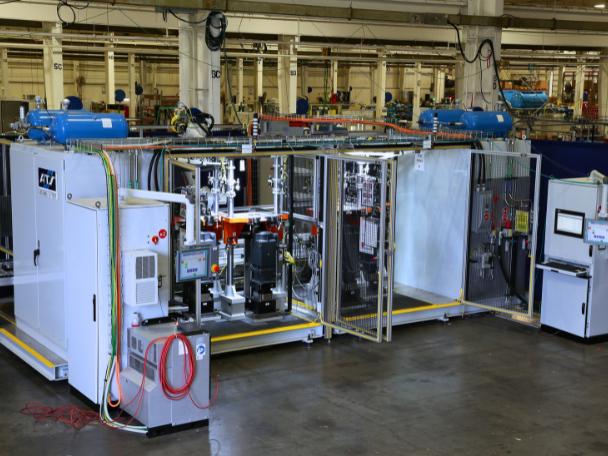

Choosing ATS Industrial Automation for the assembly and testing of eMotors can enhance precision and consistency in eMotor assembly, reduce the risk of defects, and improve overall performance. Comprehensive testing capabilities ensure each eMotor meets stringent quality standards, providing customers with confidence in the durability and reliability of their products. Our longtime expertise in automation and digitalization also helps manufacturers optimize production, reduce costs, and accelerate time to market.

Customer Challenges

Precision and Alignment: It’s challenging to ensure eMotor components such as rotors, stators, and bearings are aligned for optimal performance and longevity.

Thermal Management: Teams must manage heat generated during operation to prevent overheating and ensure the eMotor’s reliability and efficiency.

Quality Control: Manufacturers need rigorous measures to detect and address defects early in the assembly process, maintain high standards, and reduce rework.

Integration with Powertrain: Teams must carefully coordinate and test parts to ensure a smooth connection with other powertrain components, such as the inverter and battery pack.

Material Handling: It’s complicated to transport and assemble rotors and other sensitive components due to their magnetic properties and the risk of contamination.

Every eMotor project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

30

Years of Automotive Automation Experience.

110+

Battery Production Lines.

3000+

Assembly Systems Delivered.

Our Approach for eMotor Assembly

ATS uses the latest automated technologies to ensure precision and consistency in assembly. This reduces the risk of defects and enhances each eMotor’s overall quality.

Digital Twin Technology

We use digital twins to simulate and validate the assembly process before actual production to identify and resolve potential problems early.

Comprehensive Testing Capabilities

Our rigorous testing protocols verify the performance, durability, and reliability of each eMotor. This includes thermal management, vibration analysis, and electrical performance testing.

Inductive Heating

We leverage inductive heating to open the housing for stator assembly.

Customer Benefits

Optimized Square Footage

A modular approach supports multiple eMotor configurations, empowering manufacturers to adjust to changing business needs and do more with less space.

Efficient Assembly

Manufacturing leaders can benefit from digital tools such as simulations to streamline production workflows before the physical build.

Fast Cycle Time

Operations can easily scale from low cycle to high-volume production using automation.

Meet Market Demand

End-to-end assembly and testing solutions help manufacturers shorten lead times and better serve customers.

eMotor Applications

Electric Vehicles (EVs)

eMotors are essential components in cars, trucks, buses, and motorcycles, providing the necessary propulsion to drive these vehicles.

Hybrid Vehicles

eMotors work alongside internal combustion engines in hybrid electric vehicles (HEVs) to improve fuel efficiency and reduce emissions.

Industrial Machinery

Manufacturers can use eMotors in various applications, including robotics, conveyor systems, and automated manufacturing equipment.

Renewable Energy Applications

eMotors play a crucial role in renewables, such as wind turbines and solar power systems, by converting electrical power into mechanical energy.

Marine & Aerospace

eMotors are increasingly being used in vessels and aircraft for propulsion and auxiliary power, reducing carbon emissions and improving efficiency.

Home Appliances

A wide range of household equipment such as washing machines, refrigerators, and air conditioners contain eMotors, providing efficient and reliable operation.

“The team at ATS Industrial Automation are experts and truly know what they are doing. They were instrumental in helping us ramp up our eMotor assembly line.”

Large European OEM