We offer complete leak testing systems, with all the necessary tooling, seals, and precise leak rate measurement, to ensure parts meet customer expectations. Our engineers help with test process development, design, and integration of ATS GENIUS Leak Test Systems or third-party solutions. We customize each system to specific part requirements, test methodology, throughput, and automation needs. Each system is designed for maximum flexibility, ensuring it meets exact specifications and production needs.

For over 30 years, ATS has delivered reliable test systems measuring pressure decay, vacuum decay, mass flow, and functional tests on high-speed assembly lines. If you are testing for gas or liquid leaks or protecting against dust ingress, our experts can develop the ideal leak measurement and test system.

We Provide Leak Testing For

- Battery cells, modules, and packs.

- Casting porosity.

- Component subassemblies.

- Cylinder heads.

- Electrolysers.

- Engine oil galleries.

- Engine water cavities.

- Fuel cells.

- High pressure systems.

- Life science medical devices.

- Oil pumps.

- Transmission cases and housings.

Every leak testing project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

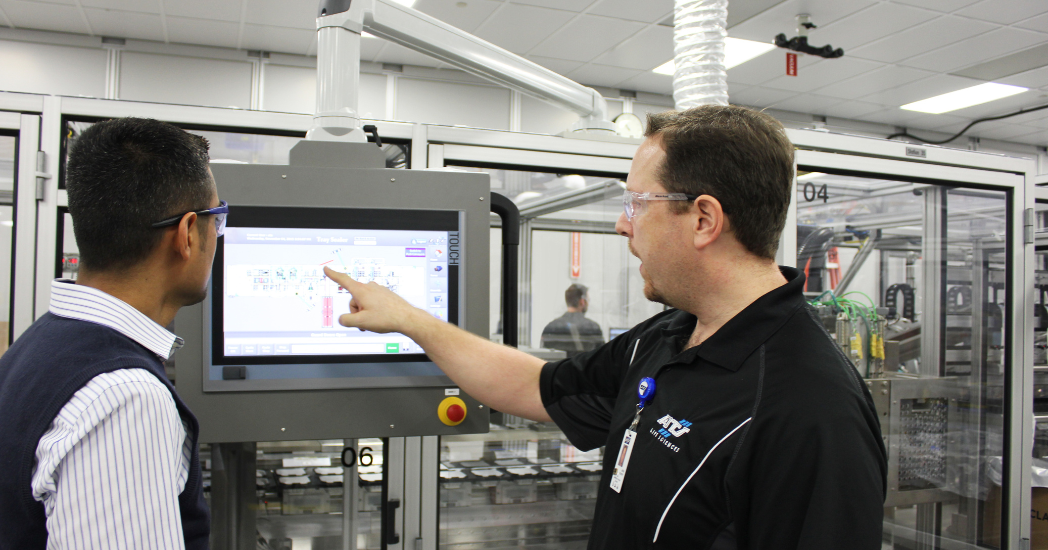

We work with manufacturers to establish leak testing needs, methodologies and deliver complete automated test systems that are tailored to a customer’s application and assembly production requirements.

Proof of Concept

Validate test methods, systems and processes before build, reducing operational costs.

In-Line and End of Line Testing

Support a range of leak and seal tests to help identify, remove and fix products early in the manufacturing and assembly process.

Scale

Deliver high-throughput, consistent and repeatable testing through automation.

Streamlined Escalation

Efficient online service escalation to minimize downtime.

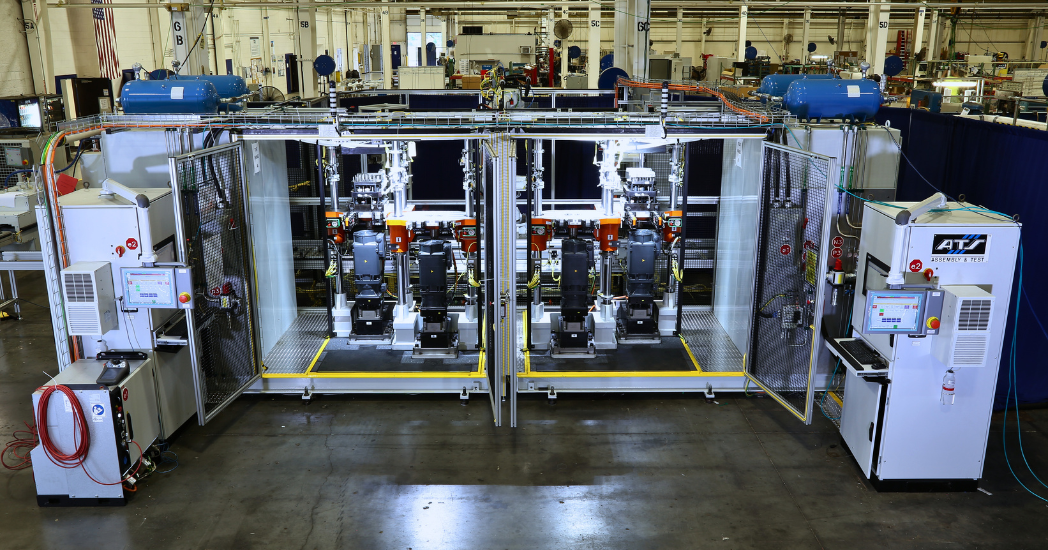

ATS GENIUS Leak Test System

The ATS GENIUS Leak Test System is an easily configurable, automated leak testing system for assembly and production lines. Available as a standalone, manually loaded unit or fully integrated automated system, it features a robust control unit with integrated electronics and an intuitive HMI. Its remote units ensure precise, rapid testing by positioning instrumentation near the device under test (DUT). The advanced software supports up to four independent leak tests, with extensive customization options for sensors, alarms, and third-party integrations, all built on the reliable ATS Test Executive platform.

Benefits of Leak Testing

Minimize Warranty Claims

Protect the brand and consumer by ensuring products meet specifications reducing field failures.

Higher Quality Products

Identify, remove, and fix early in the process.

Performance Compliant

Ensure products meet or exceed testing performance requirements.

Leak Testing Methods

Differential Mass Flow & Pressure Leak Testing

Differential mass flow and differential pressure test measure the integrity of sealed systems. Differential pressure tests focus on changes in pressure over time and is used across a wide range of applications. Differential flow tests focus on the flow rates into and out of a system and are more sensitive to small leaks, making it an ideal test for high-precision applications. Both tests are used in large-volume automotive applications such as battery module and pack assembly manufacturing, ensuring production continues without interruption.

Pressure Decay Leak Testing

A pressure decay test (PDT) is a leak test that measures the loss of pressure over a set period. A drop in pressure indicates a leak. It is one of the most common and effective leak tests for small-volume products. It is used in fuel cell and electrolyzer testing, as well as medical applications. It can be easily automated and integrated into production and assembly processes.

Vacuum Decay Leak Testing

Used to ensure integrity and airtightness in sealed systems or packages, vacuum decay tests measure the loss of vacuum over time to detect leaks that may enter from the outside such as water. This test is used in everything from battery pack manufacturing to pharmaceutical, food packaging, and medical device manufacturing.

Tracer Gas Mass Spectrometry Leak Testing

Tracer Gas Mass Spectrometry is a highly sensitive test for extremely tight leak specifications or a zero-leak environment. It involves introducing a tracer gas, either helium or hydrogen, into the system and using a mass spectrometer to detect and measure the presence of the gas escaping from any leaks. Tracer Gas Mass Spectrometry testers are used in fuel cell manufacturing and high-pressure applications such as fuel rails, fuel lines, refrigeration or air conditioning lines.

Hydrostatic Leak Test

Leak-free operation is essential in fuel cells and elctrolyzers to prevent loss of hydrogen and oxygen gases. Hydrostatic leak testing involves verifying the integrity and strength of fuel cells and electrolyzers by filling them with a liquid, typically water, and applying pressure.