Leveraging our experience designing EV battery assembly lines, we are helping the energy industry design and scale battery manufacturing for grid energy storage. With a comprehensive product offering, we provide customers with a modular and flexible platform for manufacturing and testing battery storage systems. Our proven processes, project management skills, and global reach enables customers to manage the rapid changes happening in energy storage to meet demand and stay within budget.

Customer Challenges

Ramping up production efficiently in new regions to meet growing demand.

Managing evolving battery designs and change requests as technology and chemistry evolve.

Finding the right global partner with expertise in moving from pilot to full-scale assembly.

Establishing rigorous testing for in-process and end-of-line assembly.

Every grid storage project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Partnering with our customers, we simultaneously engineer to develop processes and battery assembly systems for grid energy storage, including in-depth testing to validate the battery assembly process.

Simultaneous Engineering

Maximize assembly efficiency and minimize risk by designing for manufacturing to enable high-volume production.

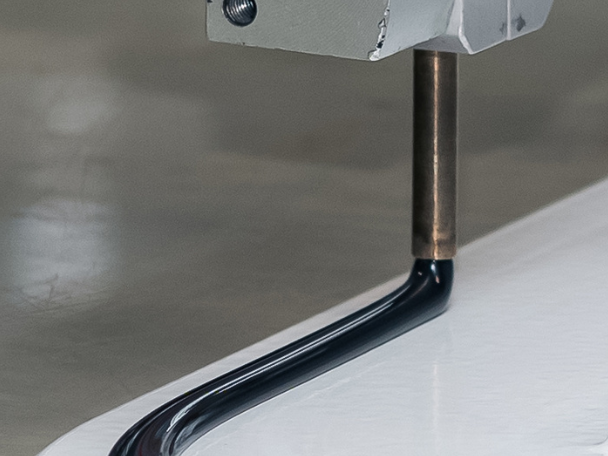

Automated Dispensing

Utilize automated dispense technology for consistent material application.

Monitor & Trace

Leverage ATS Illuminate™ Manufacturing Intelligence to monitor and trace the product as it moves through the assembly process.

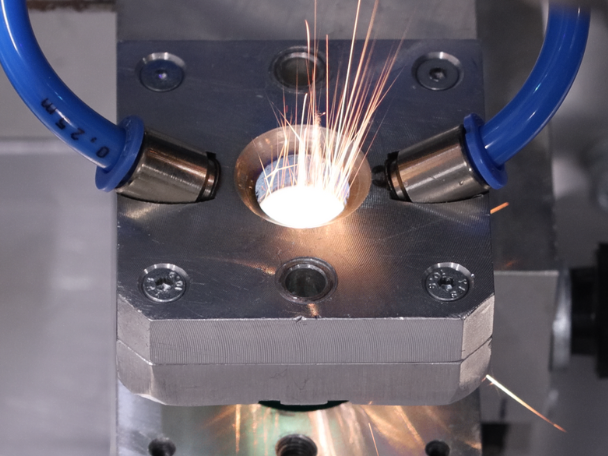

Welding

Automate and define the ideal weld using laser, resistance, or ultrasonic technology.

Robust Testing

Implement key leak and electrical testing for non-standard platforms.

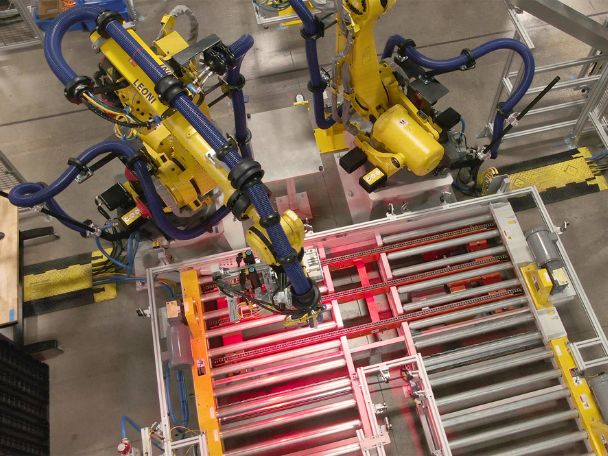

Material Handling

Develop ideal handling processes for both incoming and outgoing material.

Customer Benefit

Speed to Market

Shorten the time frame to produce sellable products.

Cost Savings

Streamline processes and production before build, reducing operational costs.

Scale

Move from kilowatt hours to gigawatt hours.

Resources

Expertise and access to operational capacity to execute large programs.

Flexibility

Support for the battery design evolution.