At ATS Industrial Automation, we leverage over 30 years of experience serving the automotive industry to provide advanced automation technologies that deliver precision and reliability for electric vehicle (EV) battery assembly and powertrain assembly, from eMotor and eRotor to inverter and eAxle systems.

Our comprehensive solutions ensure seamless integration, rigorous testing, and continuous improvement, helping eMobility manufacturers achieve optimal performance and efficiency in their electric vehicle powertrains.

30

Years of Automotive Component Assembly Experience.

10M

EVs on the Road According to the IEA.

110+

Battery Production Lines.

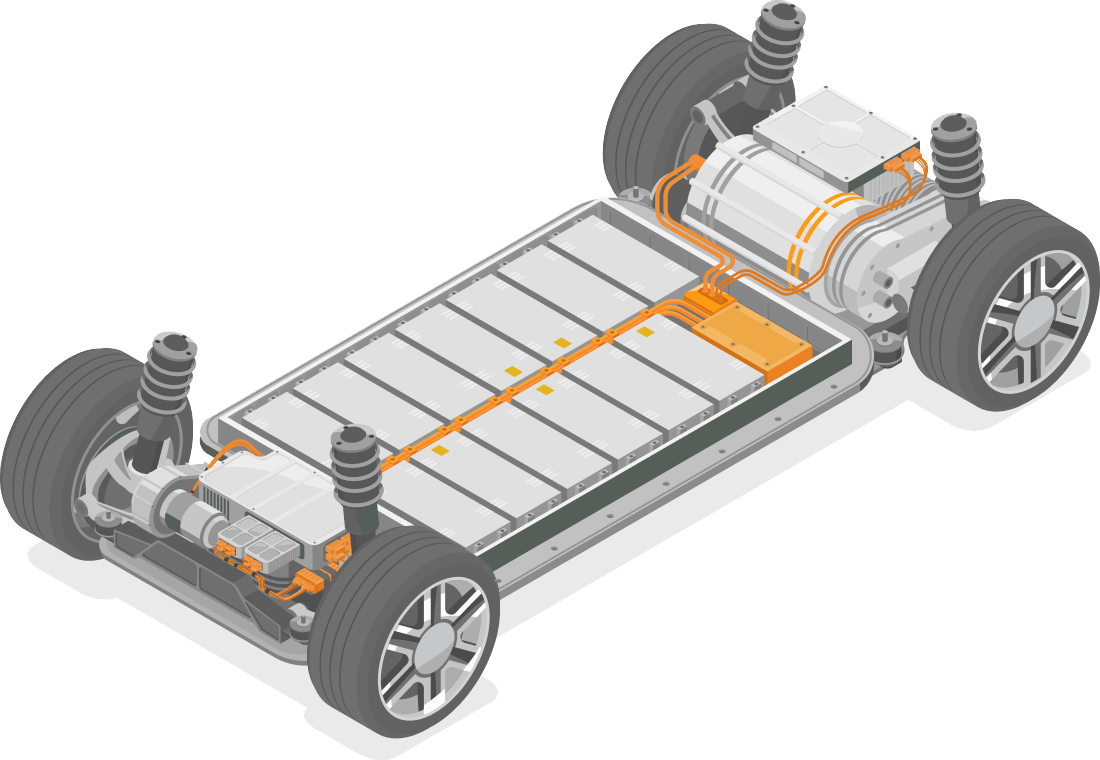

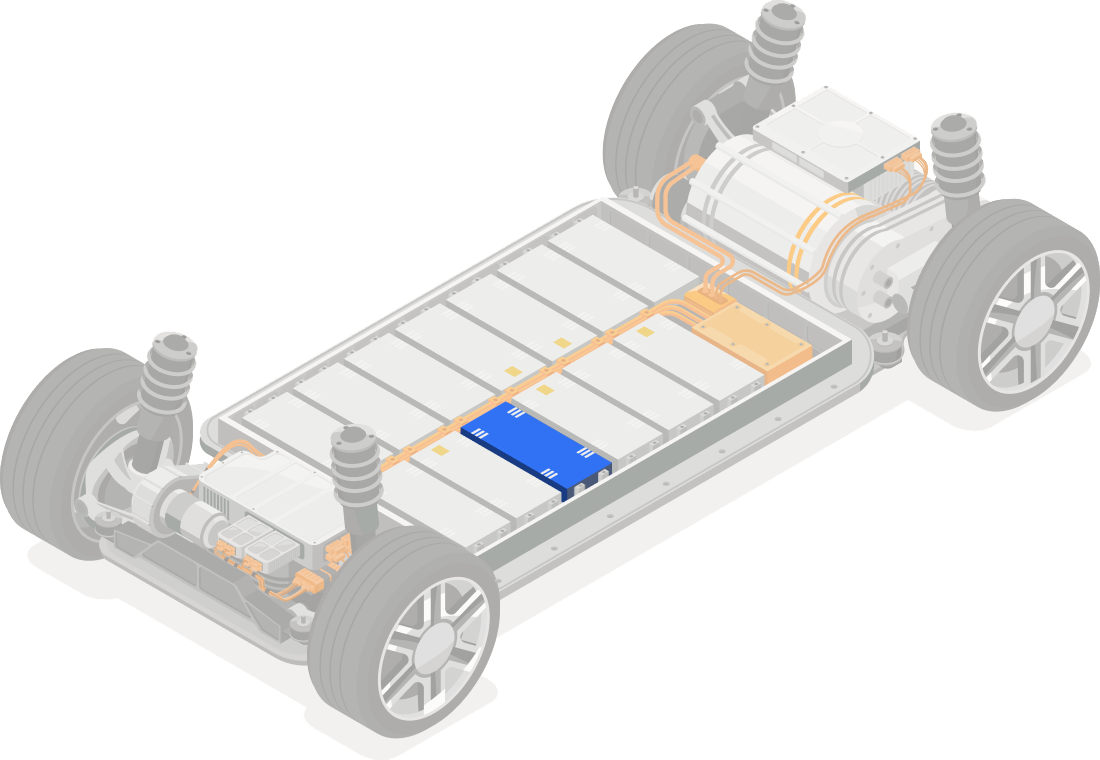

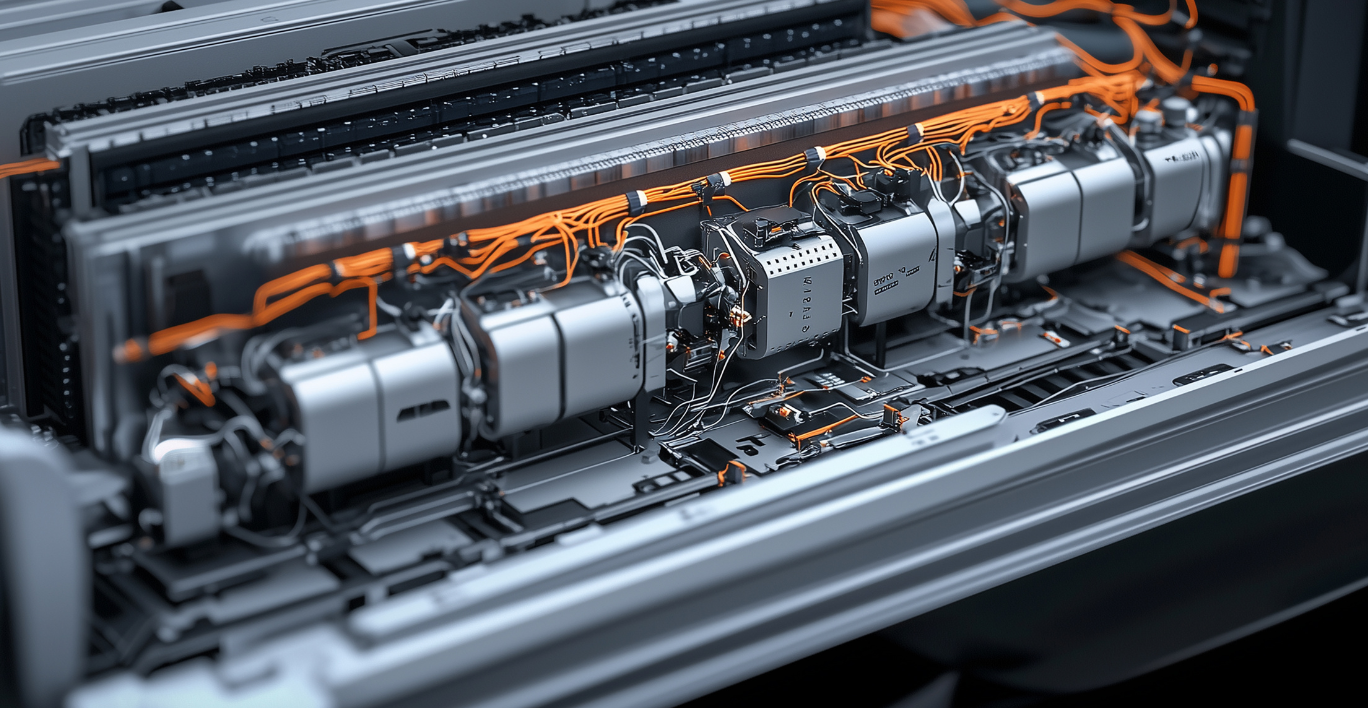

Battery Assembly & Testing

ATS offers innovative capabilities for battery manufacturing and testing, leveraging over 30 years of industry knowledge to help original equipment manufacturers (OEMs) and their Tier 1 suppliers transition from the pilot line to full-scale production efficiently and cost-effectively. Our modular and flexible systems support various EV and battery energy storage system (BESS) configurations, ensuring high-throughput and consistent quality. With a focus on precision and rigorous testing at every stage, we help eMobility manufacturers meet market demand.

Every eMobility project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

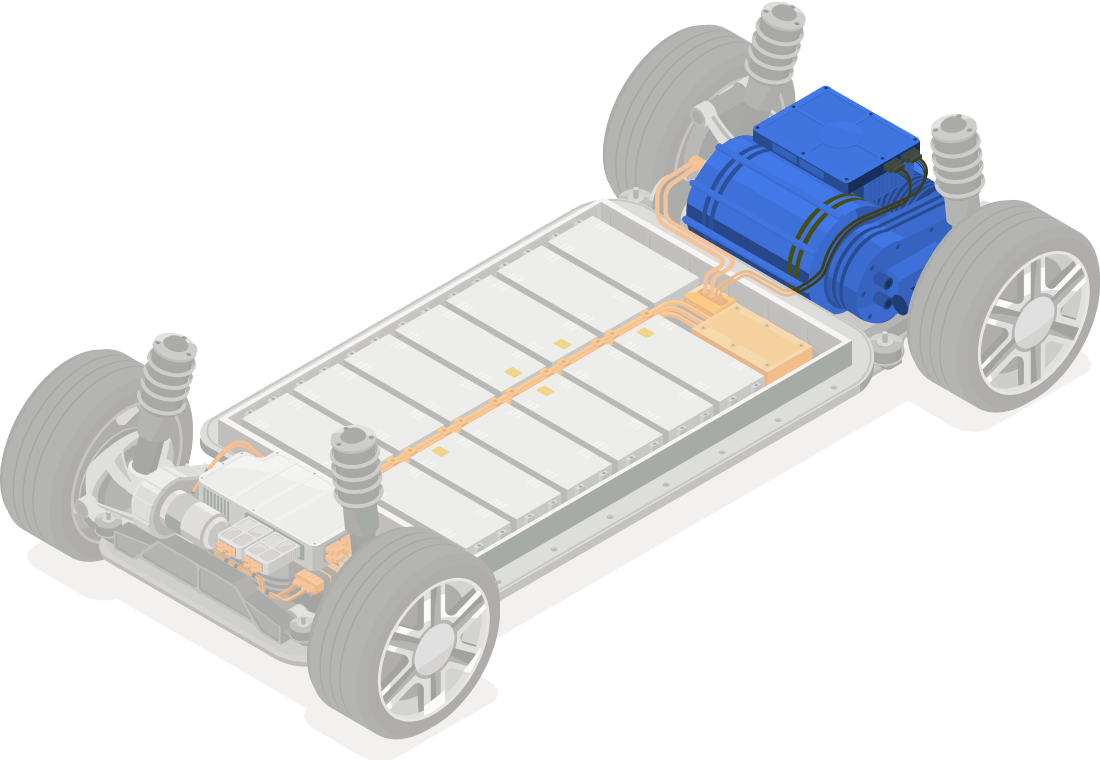

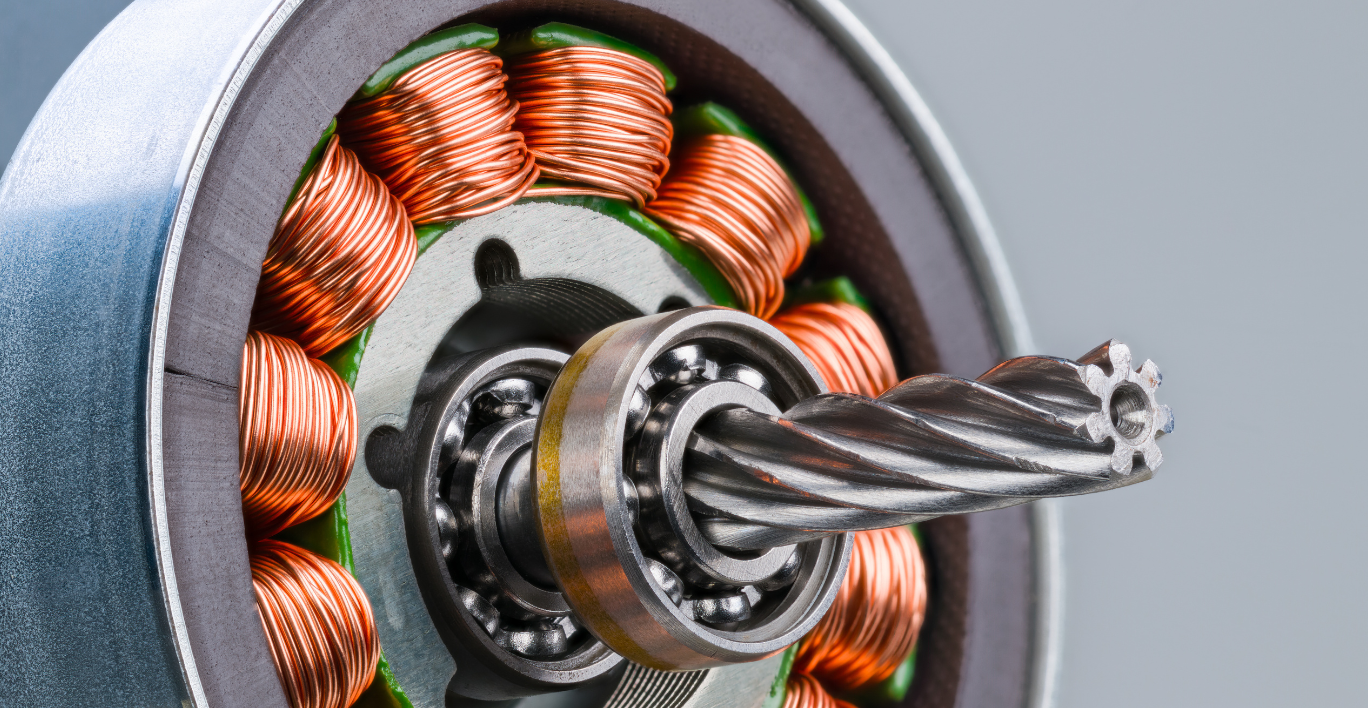

eMotor Assembly & Testing

We deliver automated assembly systems for rotors and eMotors. Our modular approach allows eMobility manufacturers to heat, assemble, cool, mount, and grease electric drive motors. Our flexible options also support multiple engine configurations, helping manufacturers create a high-quality alternating current (AC) and direct current (DC) eMotor.

eRotor Assembly & Testing

Our end-to-end eRotor manufacturing solutions are designed to enhance the efficiency and reliability of EV powertrains. Advanced automation technologies create precise assembly workflows that minimize human error, while rigorous testing protocols ensure each eRotor meets the highest performance standards. What’s more, these customized offerings meet eMobility manufacturers’ specific needs, ensuring seamless integration with other powertrain components.

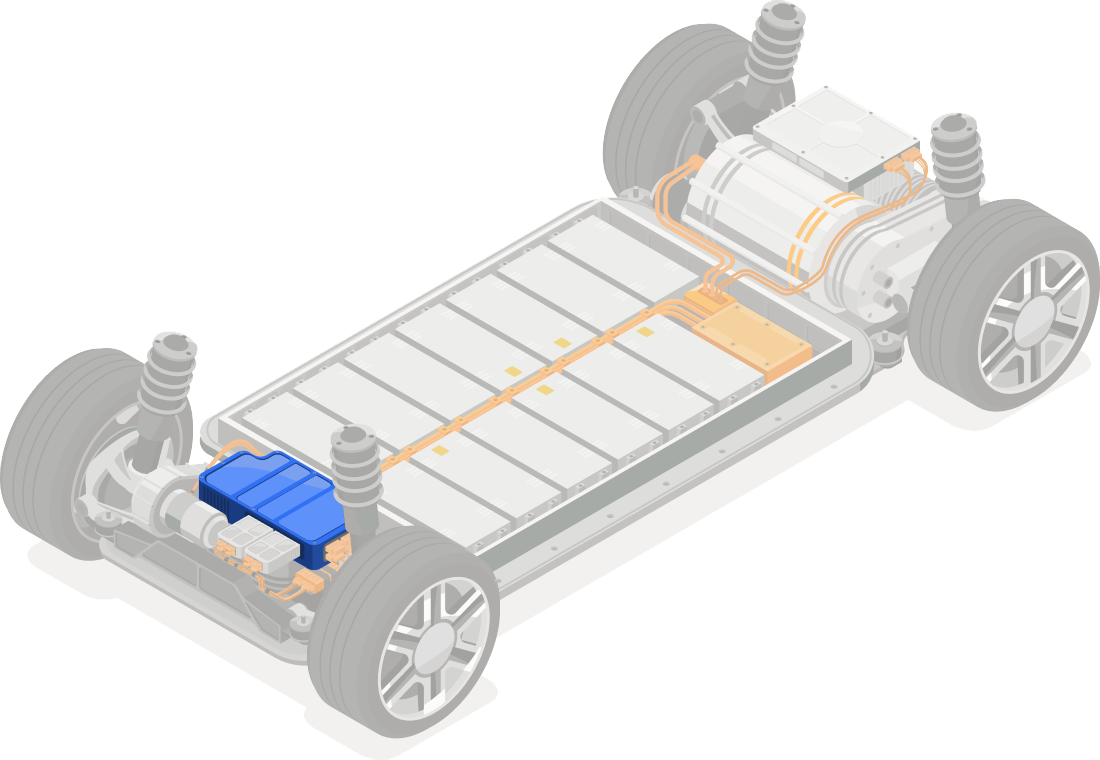

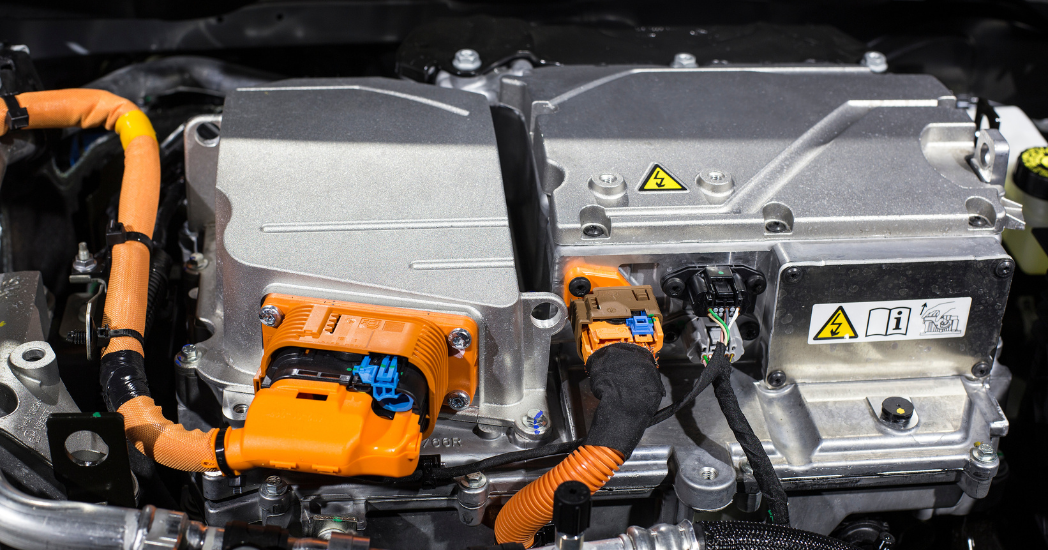

Inverter Assembly & Testing

Discover how our ATS inverter assembly solutions enhance EV efficiency. Our precision engineering drives reliable inverter production, while advanced testing capabilities facilitate optimal performance. With a focus on clean room assembly and rigorous quality control, our sophisticated inverter solutions meet the highest standards of reliability and performance.

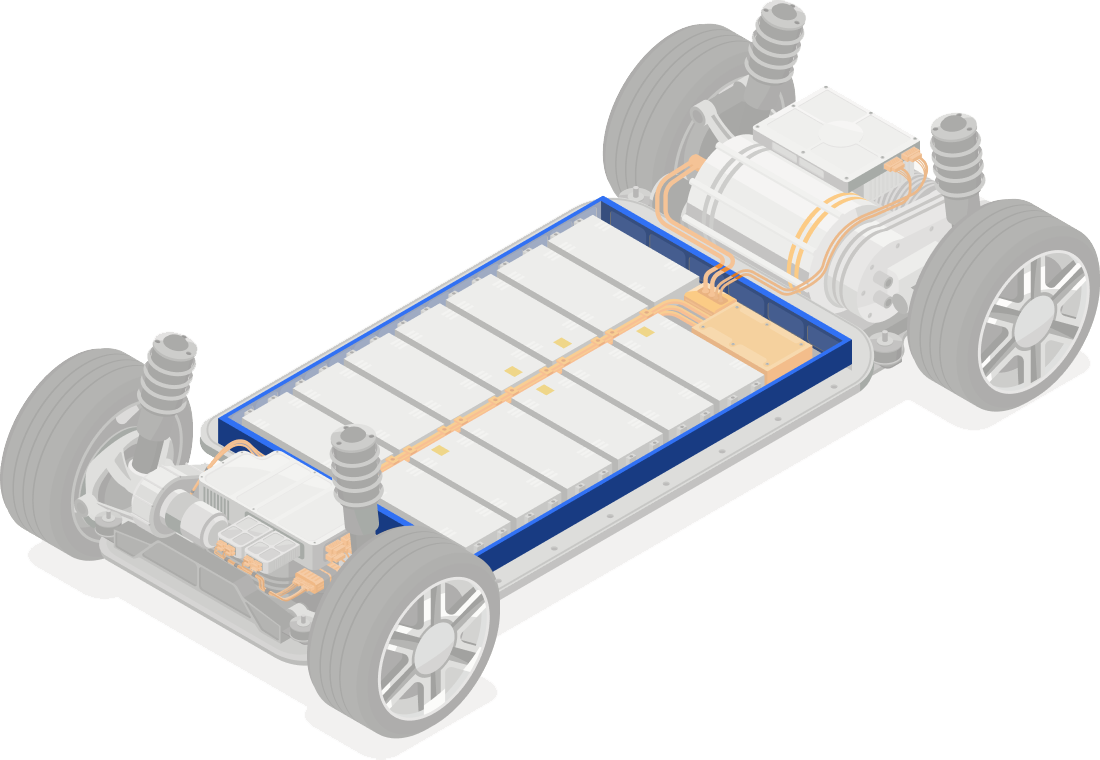

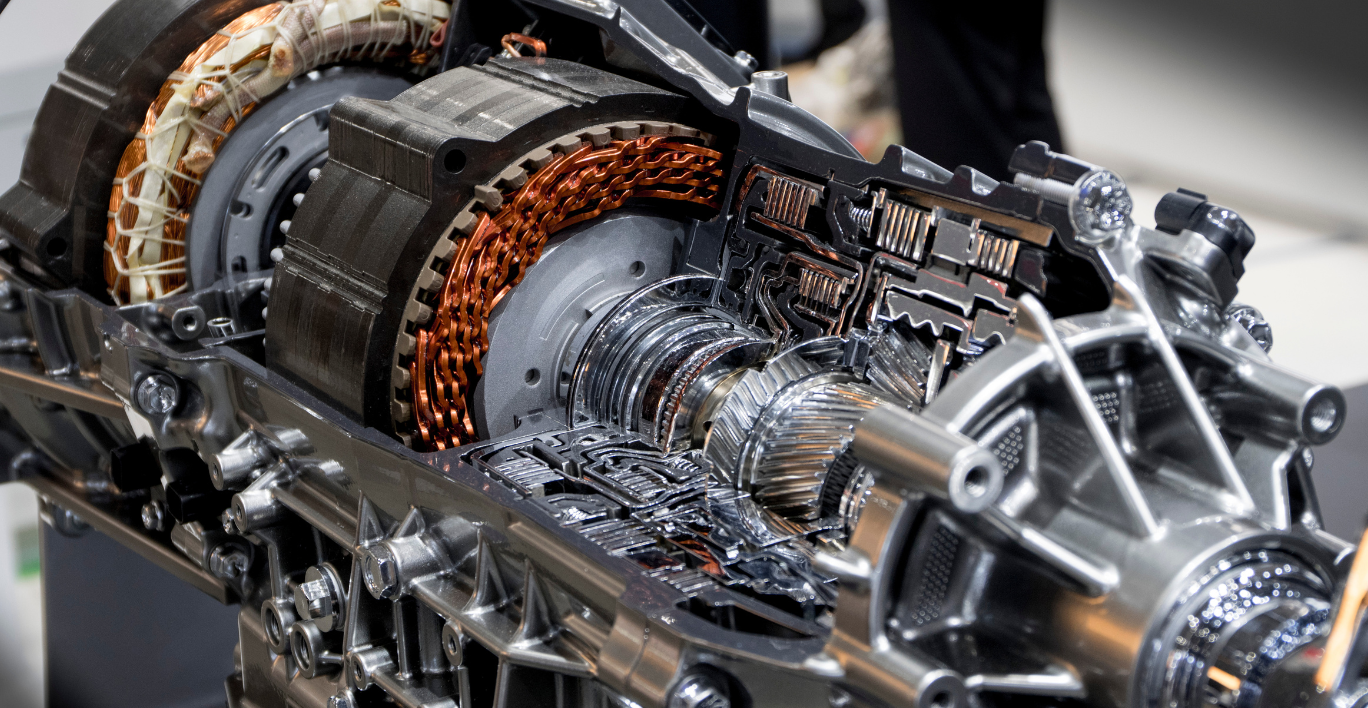

eAxle Assembly & Testing

Our eAxle solutions are designed to enhance the performance and efficiency of EVs. By integrating advanced automation, precise material handling, and thorough testing options, we help manufacturers reach optimal functionality and reliability. With a focus on seamless integration, quality control, and the latest technological innovations, our approach drives a streamlined, efficient production process that meets high performance and safety standards.

Vehicle Sub-Component Assembly & Testing

We provide various automotive sub-component solutions, including parts assembly, precision tooling, and material handling. Our systems use robotics, advanced vision technology, lasers, conveyance systems, and other innovations so manufacturers can deliver high-quality vehicle components.

Fuel Cell

Take fuel cell assembly beyond concept and manual processes. We offer automation, assembly, and test solutions for fuel cell systems in emission-free vehicles. Our custom solutions can be used in the manufacturing of cells and stacking. Our testing solutions monitor the process and verify the quality of each cell.