We provide the nuclear industry with mission-critical automation and remote tooling systems focused on streamlining reactor maintenance, reducing downtime, increasing situational awareness, and creating a fail-safe environment for operators. Our solutions enable the remote visual inspection of reactor components for evaluating damage and degradation to verify the component integrity for regulatory requirements. With remote tooling and automated delivery systems, nuclear power plants can reduce critical path activities and worker dose to provide a safe, efficient path for maintenance and inspection activities.

Customer Challenges

Shortening critical path and creating a schedule that teams can rely on.

Reducing human error by standardizing training and automating operations.

Lowering operator dose and ensuring personnel safety.

Creating a reliable and repeatable process that optimizes performance.

Every nuclear operations & maintenance project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Partnering with our nuclear customers, we continuously engineer, build, and test remote tooling systems and processes used in nuclear power plant maintenance and operations.

System Inspections

Our SmartVision™ remote inspection systems allow for the remote visual inspection of multiple areas simultaneously.

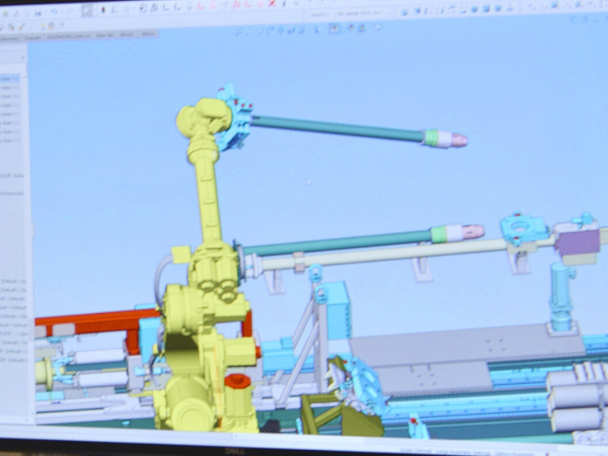

Digital Simulation & Emulation

Mitigate and verify tooling, processes, and environmental risk using digital twin technology.

Real-Time Data Analysis

Leverage Illuminate™ software for detailed reporting dashboards and notifications.

Training & Service Experts

Leverage SmartCoach™ and digital twin for employee training along with on-site experts.

Customer Benefits

Shorten Schedule

Using proven and reliable methodologies, to expediate the execution and delivery.

Risk Reduction

Diagnose, troubleshoot, validate, and proactively prepare.

Improve Safety

Reduce human error and objectively measure human performance.

Reduce Exposure

Remove or reduce humans from high-dose areas.

Operational Insights

Improve performance and maintenance with data and metrics.

“The automation technology developed by ATS is one example of how we are combining innovative new technology with proven best-practices and industry expertise that will enable improved performance and efficiency while maintaining the highest standard in safety and quality in our refurbishment program.”

Eric Chassard,

Executive Vice President of Projects and Engineering at Bruce Power.