With over 20 years of experience in the nuclear industry, we offer innovative automated solutions for various stages of the fuel fabrication process for various reactor types including:

SMR/Micro Reactors

PWRX

CANDU

Newer types of fuel such as triso

With a global presence, we can offer localized support options throughout the lifecycle of fuel fabrication project.

Fuel Fabrication Challenges

Increasing Production – Developing efficient and cost effective processes to increase the number of fuel assemblies/bundles that are being produced daily.

Outdated Technology – Aging factories contain old technology leading to increased risks and inefficiencies.

Cost of Quality & Failure Rates – Reduce failure rates during rod loading, assembly welding, spring insertion, and other processes/functions during the fabrication cycle. Ensuring that the fuel meets rigorous compliance standards to operate safely in the reactor.

Efficiency & Reliability – The dimensions of the fuel pellets and other components of the fuel assembly must be precisely controlled to ensure consistency in the characteristics of the fuel.

Safety – Reduce exposure or contamination.

Waste Management – A crucial aspect of the fuel fabrication process, involving careful handling, treatment, and disposal of various types of waste to protect human health and the environment.

Enhance the efficiency of your fuel fabrication processes. Talk to an automation expert today.

What is Fuel Fabrication?

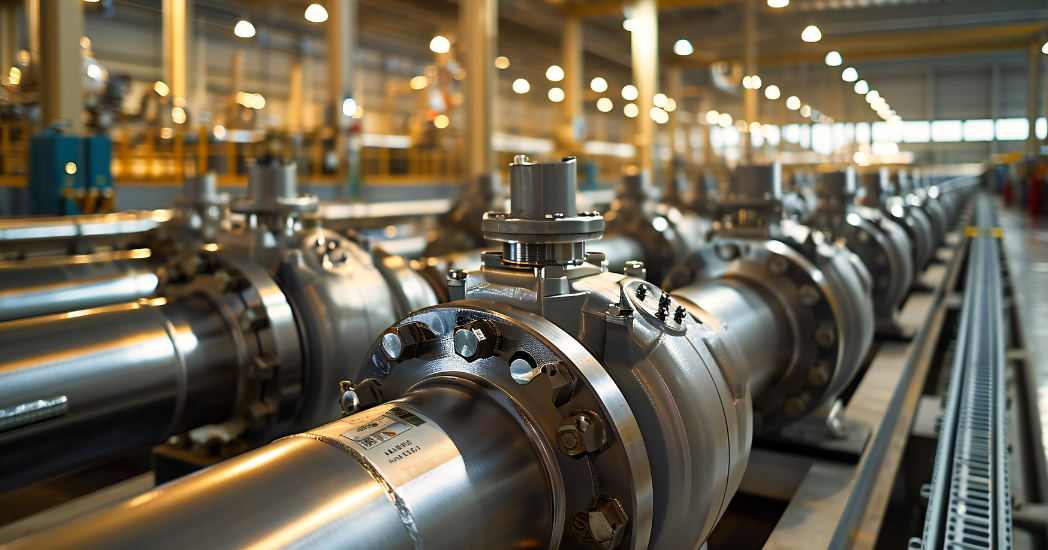

Fuel fabrication is the last step in the process of turning uranium into nuclear fuel rods. Batched into assemblies, the fuel rods form the majority of a reactor core’s structure.

Fuel structures need to maintain their shape and integrity over a period of several years within the reactor core, thereby preventing the leakage of fission products into the reactor coolant.

Our Approach

With over 20 years of nuclear tooling experience, we specialize in engineering, designing, building, and testing groundbreaking technologies in collaboration with our nuclear partners. Our expertise lies in creating automated solutions tailored for the nuclear industry.

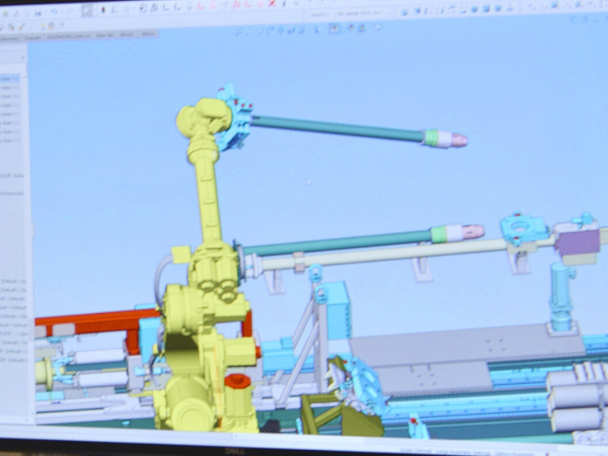

Digital Simulations

Leverage digital twin technology to model reactor design and fuel fabrication to understand the behavior of automated tooling.

Reusable & Robust Tooling

Designed and tested for high-risk environments and repeatable tasks.

Customer Benefits

Newer technologies offer potential benefits for increased production, reliability, safety and innovative solutions for the research and development of new plants for emerging types of fuel fabrication such as triso fuel.

Increased Production/Faster Cycle Times

Operating at higher speeds and for longer periods of time, automated tools for various stages in the fuel fabrication process lead to increased productivity.

Higher Efficiency

Automated tools can reduce human error and lower labour costs. They can be more energy-efficient and require less maintenance, leading to cost savings over time .

Increased Quality

Automation ensures consistent production quality by adhering to exact specifications, reducing variability in the final product. By providing detailed records of the fabrication process, automation can enhance traceability and accountability for quality assurance.

Improved Safety

Automated systems can be monitored and controlled remotely, reducing the need for human workers to be directly involved in potentially hazardous processes, decreasing the risk of exposure to radioactive materials and harmful chemicals.

Where Automation Can Help During the Fuel Fabrication Process:

Automated Tooling For:

- Powder Preparation/Pellet Manufacturing Loading Powder Into Mixing Cones

- Pellet Grinding

- Pellet Stacking

- Sheath Tube Brazing

- Sheath End Weld Prep

- Laser Cleaning

- Serialization for Component Tracking/Barcode Marking

- Press & Inspection

- Rod Loading

- Spring Insertion and Welding

- Non-Destructive Examination(NE) and Leak Testing

Vision & Quality Inspection of pellets collect and analyze data in real-time, providing insights into the fabrication process and enabling quick adjustments to optimize performance.

Waste Management – Automation can improve the sorting, handling, and disposal of waste materials, making the process more efficient and environmentally friendly.

With a vast team of experts, we can automate most parts of the fuel fabrication process, talk to our team of experts today about your process.