Stationary fuel cell power systems provide clean, reliable off-grid and backup power for remote locations and critical infrastructure. We help manufacturers commercialize and scale stationary fuel cell designs. Our extensive design, automation, and test capabilities ensure that the fuel cell stack and assembly process meet performance and reliability while reducing the cost of getting to market.

Customer Challenges

Scaling production of stationary fuel cell systems beyond manual processes.

Handling and stacking while maintaining extremely tight tolerances and cleanliness specifications.

Lowering production costs without sacrificing quality and reliability.

Developing end-of-line testing for both membrane and final product.

Every fuel cell system is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Partnering with our customers, we develop processes and simultaneously engineer systems to develop stationary fuel cell assembly systems quickly.

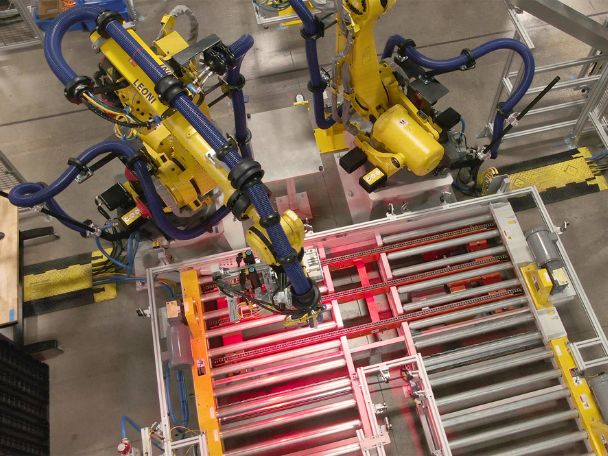

Automate Material Handling

Delicately and precisely automate the material handling of the membrane electrode assembly (MEA) to the bi-polar plate within the stack.

Membrane Electrode Assembly

Automate the membrane electrode assembly (MEA) stack with in-process performance testing.

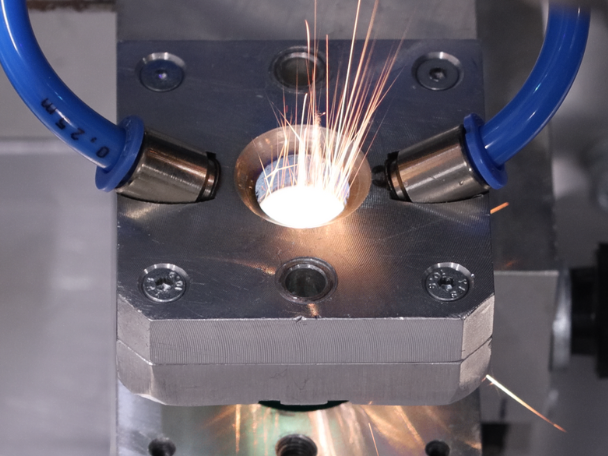

Intelligent Welding

Achieve a reliable zero gap with our intelligent welding while working around the intricate geometry of the fuel cell design.

End-of-Line Testing

Provide compressive end-of-line test suite, including closed system leak tests.

Customer Benefits

Scale

High throughput, consistent and repeatable stationary fuel cell assembly through automation.

In Process Testing

Validates stacking and assembly as it moves through the process.

Cost Savings

Control costs with an integrated design and sourcing team.

Efficient

Use digital simulation to streamline process and production before build.