An inverter is a crucial component in electric vehicles (EVs). It rapidly switches the direct current’s (DC) polarity, creating gated alternating DC that mimics alternating current (AC). This switching controls the stator’s magnetic field, driving the rotor’s motion and generating mechanical power to the motor.

Other electric powertrain components, such as the electric motor (eMotor) and electric axle (eAxle), significantly impact the inverter’s performance. The eMotor’s efficiency and power output both influence the inverter’s workload and thermal management capabilities. What’s more, the delicate components of the printed circuit boards (PCBs) must be carefully handled to ensure the inverter works properly.

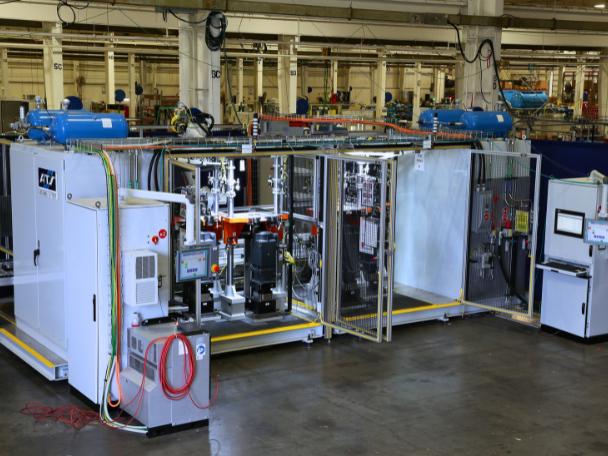

With 30+ years of automotive industry experience in automation and design for manufacturability (DFM), ATS Industrial Automation offers innovative solutions for complex production workflows. Advanced facilities and testing capabilities ensure manufacturers can assemble inverters with confidence and meet the highest quality standards.

Customer Challenges

Part Tolerances: All parts must fit together precisely. Poor tolerance schemes can lead to increased costs to ensure proper assembly.

Cooling Integration: It can be challenging to manage coolant during testing and remove it afterward to avoid corrosion.

Pin Positioning: Manufacturers must accurately place pins during assembly. Misalignment can cause significant issues during PCB installation.

Cable Management: Properly positioning cables throughout assembly ensures reliable connections.

Surface Cleaning: Impurities can affect solder joint quality, so teams must thoroughly decontaminate surfaces to improve adhesion properties.

Magnet Alignment: It’s crucial to carefully handle magnets to prevent damage and reduce wear on the inverter.

Every inverter project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

30

Years of Automotive Automation Experience.

110+

Battery Production Lines.

3000+

Assembly Systems Delivered.

Our Approach

Testing & Validation

Our thorough testing solutions ensure the inverter’s reliability. We also manage coolant introduction and removal during each test.

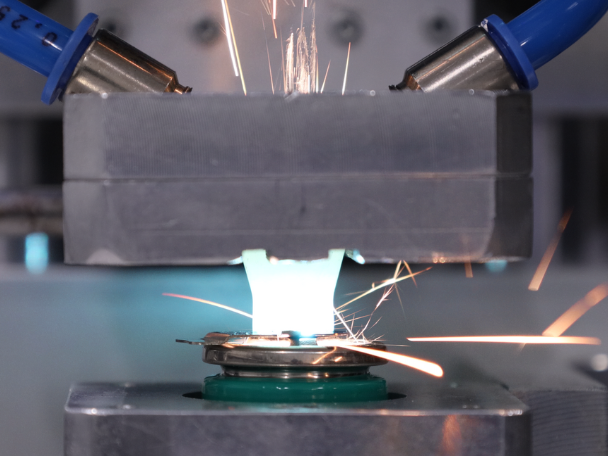

Precision Welding & Soldering

Our laser welding, automated soldering, and real-time monitoring achieve strong bonds, minimizing thermal distortion and defects in the inverter.

Customer Benefits

Design for Manufacturability

Our DFM workshops empower customers to refine their designs. We simultaneously build automation equipment and use digital tools to improve processes, helping manufacturers get high quality products to market faster.

Data-Driven Insights

Real-time analytics let customers monitor and analyze assembly workflows and make informed decisions that optimize processes.

Fast Cycle Time

Manufacturers can easily scale from low cycle to high-volume production using innovative automated solutions like SuperTrak CONVEYAVNCE™.

Efficient Assembly

We leverage digitalization tools, such as simulations, to streamline production workflows before the physical build.