An electric axle, or eAxle, is an integrated unit that combines an electric motor, power electronics, and transmission into one compact system. This innovative component powers the wheels of electric vehicles (EVs), providing a more streamlined solution compared to traditional internal combustion engines. The eAxle plays a crucial role in EVs, offering benefits such as reduced weight, increased efficiency, and improved performance.

An eAxle is influenced by other powertrain components. The inverter manages the flow of electrical energy from the battery to the electric motor (eMotor), which converts that energy into mechanical power. Inefficiencies in these components can impact the vehicle’s acceleration, range, and energy consumption.

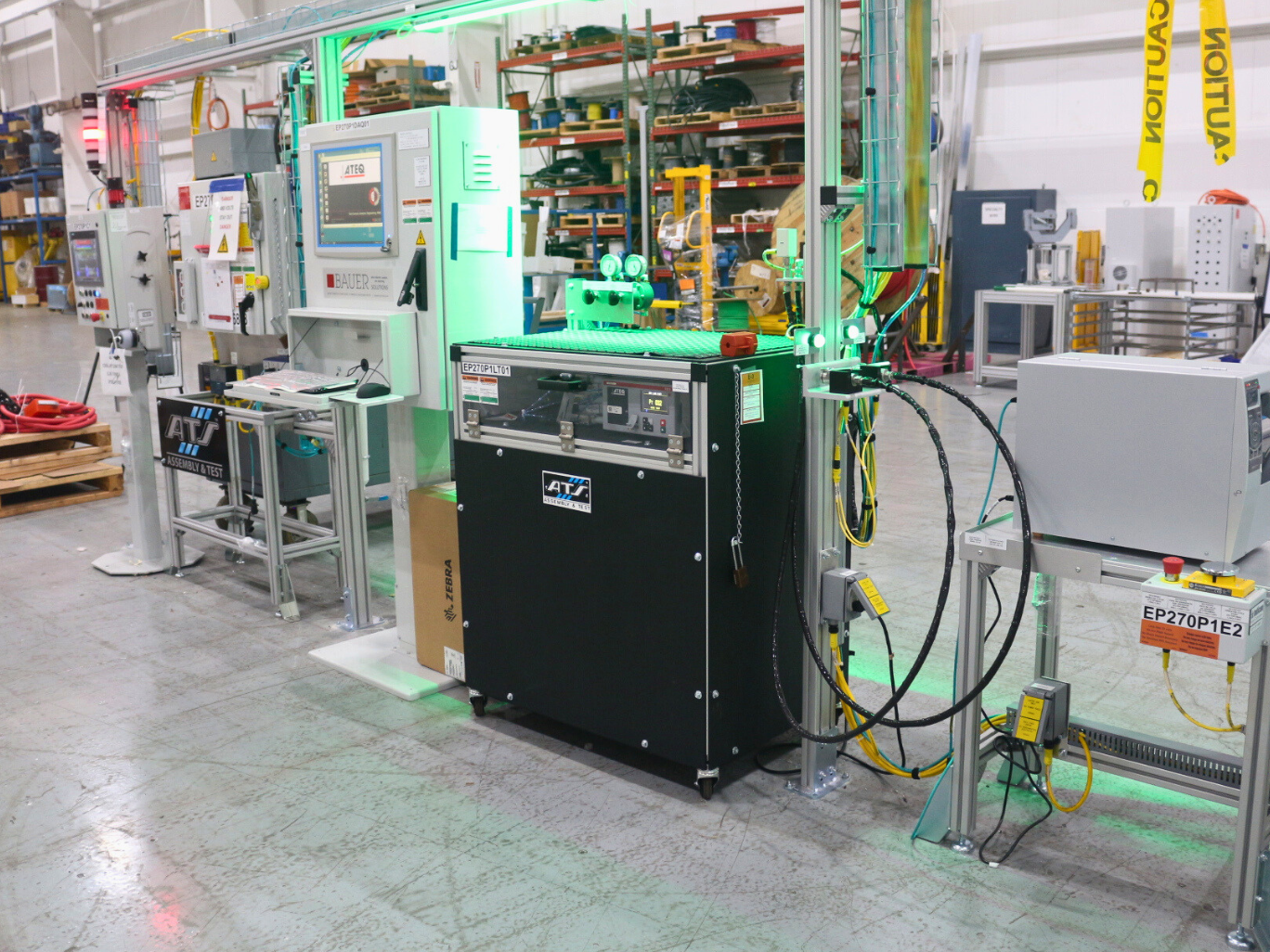

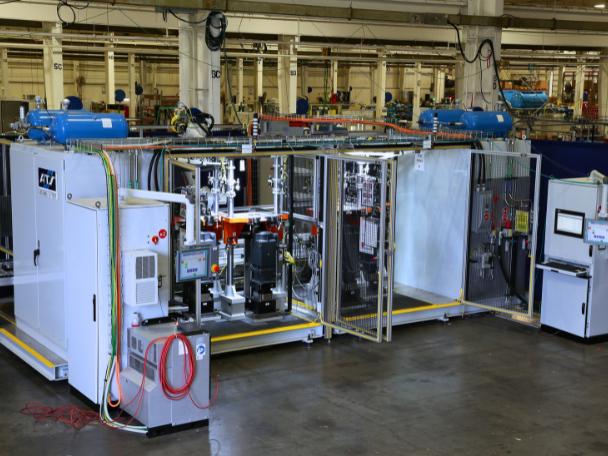

ATS Industrial Automation’s comprehensive assembly and testing solutions give manufacturers confidence in their processes—driving the production of reliable eAxles. Our 30+ years of experience in automation for the automotive industry helps manufacturing teams optimize production, reduce critical costs, and accelerate time to market.

Customer Challenges

Integration Complexity: Manufacturers often integrate the eAxle with other propulsion powertrain components, which can be complicated due to the need for precise alignment and compatibility.

Holistic Quality Control: It’s crucial to maintain high standards throughout the assembly process, not just at the end, to prevent defects and ensure the eAxle’s reliability and performance.

Testing and Validation: Teams need a comprehensive testing approach to verify the eAxle and its components reach optimal performance and safety levels.

Technological Advancements: It can be challenging to keep up with rapid innovations in EV components and ensure the assembly process incorporates these technologies.

Every eAxle project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

30

Years of Automotive Automation Experience.

110+

Battery Production Lines.

3000+

Assembly Systems Delivered.

Our Approach

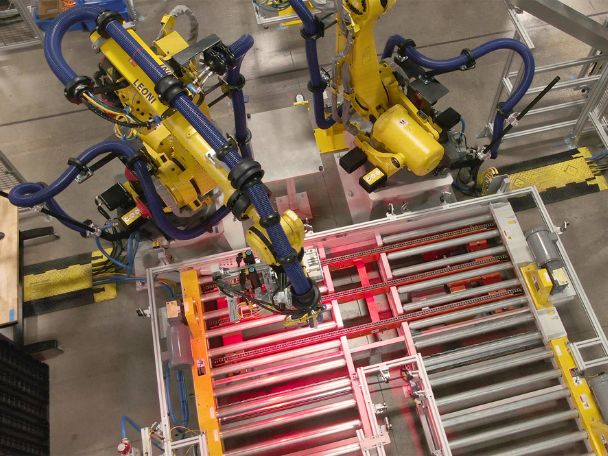

Press Assembly

Our press assembly techniques ensure all gears and pins are securely and precisely joined.

Digital Engineering

ATS uses digital twins and a system twin to virtually validate the line’s performance before it is physically built, saving manufacturers critical time and operating costs.

Customer Benefits

Optimized Square Footage

A modular approach supports multiple eAxle assembly configurations, so manufacturers can adjust workflows according to their business needs.

Efficient Processes

An experienced partner enables manufacturers to optimize designs for manufacturing, streamline workflows, and identify potential production issues before they even begin assembly. Simulations and other digital tools can support this pre-automation work.

Fast Cycle Time

Manufacturing teams can easily scale from low cycle to high-volume production using automation.

Meet Market Demand

End-to-end assembly and testing solutions help manufacturers shorten lead times and better serve customers.