ATS Industrial Automation’s high-speed, high-accuracy vision automation capabilities enable enhanced inspection efficiency and precision in various industrial applications. High-speed vision systems capable of performing numerous inspections per second using techniques such as strobing and high frame rate imaging can capture fast-moving parts without stopping for inspection or perform highly detailed inspections of rotating parts. High-accuracy vision involves using high-resolution cameras, specialty optics, traceable calibration targets and advanced calibration techniques to ensure precise measurements and feedback, even for large parts. This combination allows ATS to maximize equipment efficiency and meet strict process specifications, making it ideal for applications requiring detailed inspections and precise assembly.

With expertise across mechanical, electrical, and machine vision disciplines, ATS’s approach sets us apart from other automation partners. This comprehensive design process ensures all necessary provisions, such as specialized part handling and lighting, high-speed input/output (I/O) and precise synchronization, image transfer and storage provisioning, and integration with Illuminate™ Manufacturing Intelligence or other MES platforms are considered early on, during the design phase. Additionally, ATS leverages in-house capabilities and closely collaborates with suppliers to benchmark and validate the performance of vision systems, ensuring they meet the highest standards of accuracy and speed. This approach enables ATS to deliver robust and reliable vision solutions that enhance productivity and quality in industrial automation.

ATS’ commitment to staying updated with the latest vision certification programs and industry standards underscores the dedication to delivering excellent machine vision solutions, addressing customer challenges, and providing tailored solutions that drive productivity and quality control.

Challenges with High Speed and High Accuracy Vision

Synchronization and Integration: Ensuring that vision systems are perfectly synced with other automation equipment requires high-speed I/O, special programming techniques, and controlled part presentation.

Accuracy and Calibration: Achieving high precision in measurements demands specialized calibration tools and techniques.

Data Management: High-speed vision systems generate large amounts of information that must be stored and managed effectively for traceability and statistical analysis.

Complexity of Implementation: Designing and integrating high-performance vision systems involves balancing throughput requirements with the amount of data collected per inspection.

Every automation project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

High Speed and High Accuracy Vision Automation Helps With

Enhanced Precision

High-resolution cameras and optics deliver detailed and reliable measurements, ensuring high accuracy in inspections.

Improved Quality Control

Real-time feedback leads to more informed decision-making, allowing for the immediate identification and correction of defects.

Seamless Integration

Vision systems synchronize with other automation equipment, ensuring smooth and efficient operations within the production line.

Comprehensive Data Management

By generating and managing large amounts of data for traceability and statistical analysis, vision automation supports continuous improvement.

Versatility

High-speed vision systems are applicable to a wide range of industries and processes, from high-speed flyby inspections to precise dimensional measurements.

Certified Expertise

The ATS team of CVP-certified vision experts stays updated with the latest vision certification programs, ensuring the highest standards in designing and implementing these complex systems.

Vision Automation Applications

Flyby Inspections

Utilized in high-speed lines where parts are analyzed without stopping, maximizing efficiency and throughput. This approach is useful in industries like consumer product goods (CPG), where systems can handle up to 20 parts per second.

Dimensional Measurements

Applied in processes requiring precise dimensions, such as inspecting long cylindrical cartridges.

Quality Control

Used in applications where precise process and assembly requirements are critical. High-accuracy vision systems provide real-time feedback to ensure components are assembled correctly.

High Speed Vision

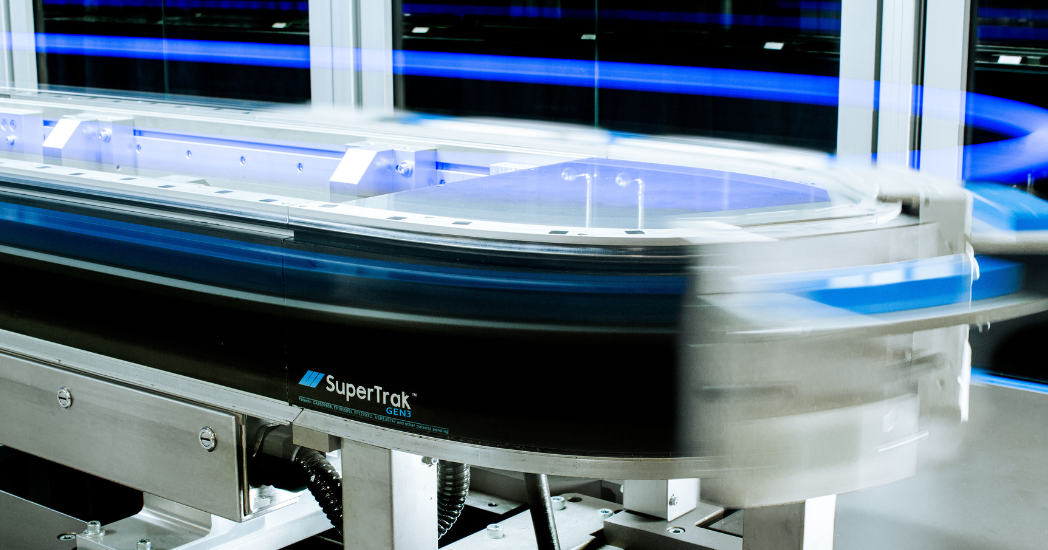

This method of vision automation involves utilizing advanced techniques such as strobing and high frame rate methods to capture parts in motion, ensuring precise, accurate inspections. Integrating visual inspection automation, such as high-resolution cameras and machine optics, delivers detailed and reliable measurements, even for fast-moving components.

Engaging an automation assembly partner to develop a high-speed system ensures seamless integration with other equipment. This ensures the systems are perfectly synchronized with the production line, enhancing efficiency and accuracy.

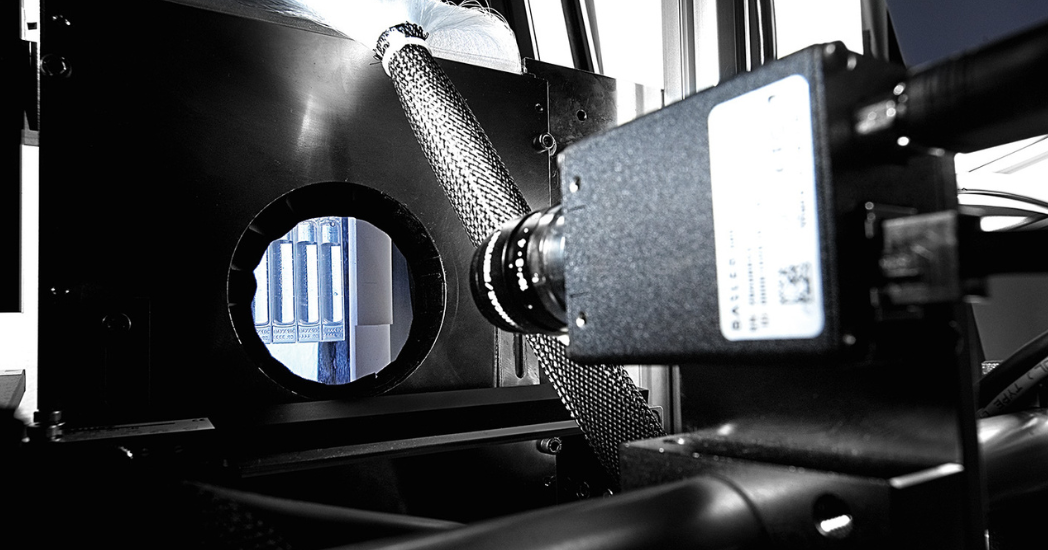

High Accuracy Vision

The approach to high-accuracy vision focuses on delivering precise, reliable measurements. This involves performing dimensional or position feedback readings to tight process tolerances, so every inspection meets stringent requirements. High-accuracy vision systems often employ multiple cameras to span large parts and utilize special optics, traceable calibration targets and specialized calibration techniques to report traceable real-world dimensions. This meticulous approach ensures that even the most complex components are measured at the highest level of precision.

Integrating high-accuracy vision systems with other automation equipment is crucial. This involves precise part handling and presentation in the manufacturing line to maintain consistent and accurate evaluations. ATS can design and implement advanced systems that not only meet but exceed industry standards.