The quality of products built on an assembly line is greatly affected by the End-Of-Line (EOL) test equipment that evaluates the manufactured part’s attributes. It is critical that the EOL machine operates at full overall equipment effectiveness (OEE) to keep up with the throughput demands of the assembly process.

Surprisingly, the weakest point of failure in the EOL machine is often the test connector that connects the EOL to the Device Under Test (DUT). Despite its importance, the connector is often treated as a low-cost commodity. This small part is the first point of contact between the test system and the product, and it can make or break the accuracy of your results.

For example, in EV battery manufacturing, the DUT is typically automatically connected using a pneumatic cylinder or servo engagement. The test connector would need to be designed with an actuated latching mechanism that fits and holds the DUT mating connection precisely.

If this connection was not designed correctly, the DUT can get stuck to the EOL machine, and if connections are poor (ie, sticky pogo pins), this will result in bad or noisy measurements. A worst-case scenario would involve electrical arcing if the contact points are not applying the correct force or are not properly insulated.

Testing plays a critical role in modern manufacturing—not just as a final checkpoint, but as a strategic tool for quality assurance, product validation, and risk mitigation. At ATS Industrial Automation, testing is more than equipment; it’s a methodology, helping manufacturers identify issues early, reduce warranty and recall penalties, and maintain a competitive edge.

Why Connections are Critical

Inconsistent or poor-quality connections can cause false positives and negatives, misidentify defective parts, or fail to catch major issues. In addition to undermining product testing integrity, it ultimately increases the risk of faulty components.

Reliable connectors are essential to proving system integrity. They ensure the fixture makes proper contact with the device under test (DUT), enabling accurate measurements while protecting the part and the equipment.

The DIY Dilemma

Many manufacturers begin the testing journey with off-the-shelf equipment like benches, sensors, and software platforms—expecting a plug-and-play experience. However, they quickly discover a critical gap: the equipment does not reliably connect to the parts. Without proper connectors and test fixturing, the system cannot complete the test cycle. This often leads to improvised solutions, such as 3D-printed housings or repurposed customer product connectors, which introduce new challenges in accuracy, repeatability, and safety.

3D-Printed Connectors: Fast Prototyping, Fragile Reality

Manufacturers may also leverage 3D printing to create low-cost, prototype connector housings during early-stage test fixturing. While it allows for quick iterations and shape validation, it lacks the durability and precision required for production environments, especially in electrical, pneumatic, or hydraulic testing. These prototypes are not suitable for high-volume production, where repeatability and efficiency are critical, and they pose safety risks from arcing and unreliable contact forces.

3D Printed Connector Advantages:

- Rapid prototyping for shape validation

- Low initial cost

- Easy customization using CAD

3D Printed Connector Limitations:

- Fragile materials prone to breakage

- No integrated latching mechanisms

- Limited tolerance control

- Inadequate for electrical, pneumatic, or hydraulic testing

- Poor scalability and maintenance support

- Safety risks due to arcing and unreliable contact force

These prototypes are not suitable for high-volume production, where repeatability and robustness are critical.

Customer Product Connectors: Familiar but Flawed

Connectors designed for final assembly are often repurposed for testing. While they match the end-use interface, they are not built for repeated engagement or integration into testing processes. These interfaces can then wear down or damage parts, compromising the accuracy and reliability of the product when subjected to high frequency use that testing demands.

Customer Product Connector Advantages:

- Matches final product interface

- Familiar to operators

Customer Product Connector Limitations:

- One-time use only; multiple insertions (connect/disconnect) will break the connector.

- Wear and tear from repeated use

- Limited support for gauge R&R and iterative testing

- No control over connector design or quality

- Risk of damaging parts during repeated connections

These connectors are not optimized for repeat part testing, and their limitations can compromise the accuracy and reliability of product testing.

What Do “Good” Results Look Like?

Achieving reliable and reproducible results is the cornerstone of effective product testing, especially in end-of-line environments. A good connection consistently delivers accurate measurements, whether the same part is tested 50 times in succession or weeks later.

To build a test system that meets these standards, manufacturers must consider several factors:

- Wiring and Cabling: The type of wire directly impacts signal quality. High-current applications require thicker wires, which can introduce electrical noise. Low-voltage measurements benefit from thin, shielded cabling to minimize interference from surrounding equipment.

- Connection Strength: The force applied during connection must be carefully controlled and balanced. Too little force can result in poor contact and electrical arcing; too much may damage the part.

- Filtering Techniques: Signal conditioning through hardware or software filters helps clean up noisy measurements. For industrial settings, hardware filters are the most reliable and consistent option.

- Electrical and Mechanical Design: Effective connectors must align with the DUT, from matching connector geometry to avoid movement during testing. This is especially critical in sensitive applications like semiconductors or plated surfaces.

- Durability and Lifecycle: The connector must withstand repeated use without degradation. Long lasting test connectors are often built with spring-loaded pogo pins and robust materials to support hundreds of thousands of insertions.

- Safety Considerations: Ill-designed connectors can cause electrical arcing, posing risks to personnel and equipment. Inadequate force control may also result in unsafe testing conditions or damaged parts. Precise force specifications, pneumatic latching mechanisms, and automated air eject features can improve operator safety.

Ultimately, a good test connection must enable accurate, repeatable, and safe measurements—without compromising the integrity of the part or test system.

Engineering for Precision

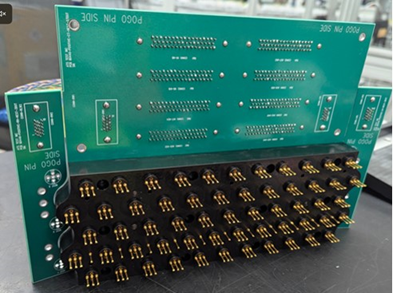

ATS Industrial Automation designs custom test connectors and test fixtures that meet the demands of industrial product testing and can seamlessly integrate into automated systems.

Key features include:

- Material Selection: Molded urethane and machined Delrin for strength and longevity

- Color Coding: Multiple color options for easy operator identification

- Strain Relief: Reinforced cabling to prevent damage from repeated use

- Ergonomic Mounting: Adjustable arms and fixtures for operator comfort and part tolerance

These components support end-of-line testing, electrical validation, and high-current applications with precision.

Custom Test Connector Example Specs for an EV Battery Application

- Current: 0-35 amps (up to 250 amps for special applications)

- Resistance: 25-50 mΩ typical

- Isolation: 200 MΩ at 5000 volts

- Contact Force: 50-350 grams typical, up to one kilogram for special cases

Customization options:

- Air release and eject mechanisms

- Military-grade connectors

- Terminal push-out detection

- High-current and Kelvin connections

- Part presence sensing

Text Fixture FAQs

What mounting options are available?

Connectors can be handheld, table-mounted, or integrated into custom test fixtures. Standard bases and operator handles reduce costs and improve usability.

What’s the difference between a test connector and a fixture?

Test connectors ensure accurate measurements by engaging the part with the correct connection attributes (i.e., force, cabling, materials, seal rating, etc.). Fixtures, on the other hand, are primarily designed to hold the part in place or engage with its surface—providing stable mechanical support during testing. While this article focuses on connectors and their role in achieving precise electrical or mechanical connections, fixtures are equally important for positioning the part correctly within the test system.

How does ATS ensure connectors don’t damage parts?

ATS analyzes computer-aided design (CAD) models, selects appropriate materials, and controls contact force. Custom latching mechanisms support safe, repeatable engagement.

What other factors should manufacturers consider for effective test measurements?

- Stable mechanical engagement

- Correct contact force

- Filtering techniques for signal conditioning

- Repeatability across multiple test cycles and time intervals

Rethinking the Connector Strategy

In manufacturing environments, such as those found in automotive manufacturing, good measurement results matter. Connectors and test fixturing are foundational to reliable, repeatable, and safe testing outcomes. They are also the most likely point of failure in a test setup. Treating connectors as engineered components leads to better data, safer operations, and more efficient production.

Testing experts at ATS Industrial Automation bring decades of experience designing and building complete test systems. Every connector is engineered to match the geometry, tolerances, and electrical requirements of the part it’s testing.

Ready to improve accuracy, repeatability, and safety in your part and product testing? Contact us today.

Every testing project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Jules Lam, M.Eng

Group Lead, Software Engineering

ATS Industrial Automation

Jules is a Test and Measurement expert with 22+ years of experience in Software Engineering. He develops testing solutions across various industries typically around challenges arising from data acquisition, signal processing, bus communications, time synchronization, and system control.