We specialize in precise adhesive dispensing to create strong, reliable bonds between materials essential for electronics, EV batteries, and automotive manufacturing industries. With expertise in dispensing and material science, we help manufacturers choose the best dispensing method and technologies for their applications.

ATS leverages advanced solutions such as robotics, vision guidance systems, dispense equipment for specialized materials, such as TIM or UV curable epoxies and finally in process monitoring to solve application challenges. We tailor dispensing systems to meet the unique needs of each project. Custom nozzles and tooling are used to optimize performance. Beyond just dispense, our team is fully capable of integrating the dispensing solutions into larger automation processes, handling complex motion profiles to ensure precise application and throughput.

Adhesive Dispensing Challenges

Understanding the unique handling and application requirements with different adhesives, including cyanoacrylates, UV curable materials, and epoxies.

Dispensing the correct adhesive volume for strong bonds while avoiding waste.

Controlling adhesive viscosity for proper flow and application.

Ensuring precise application to the target areas and preventing contamination.

Maintaining and cleaning dispensing systems to prevent clogging and keep systems running reliably.

Every automation project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Benefits of Adhesive Dispensing

Accurate & Precise

Delivers controlled, targeted adhesive application for maximum bond strength.

Reduces Waste

Dispenses precise volumes to minimize material usage.

Customizable

Tailored systems with specialized nozzles and optimized tooling to meet specific production needs.

Reliable

Comprehensive maintenance and streamlined designs ensure consistent performance with minimal downtime.

Fully Integrated Production Lines

Seamlessly integrate dispensing equipment into automated production lines to maintain high production rates.

Efficiency & Speed

Accelerates production by automating repetitive tasks for faster throughput.

Applications of Adhesive Dispensing

Our adhesive dispensing systems are used across industrial applications to create strong and reliable bonds between materials and are useful gap fillers for thermal transfer, isolation and other mechanical properties.

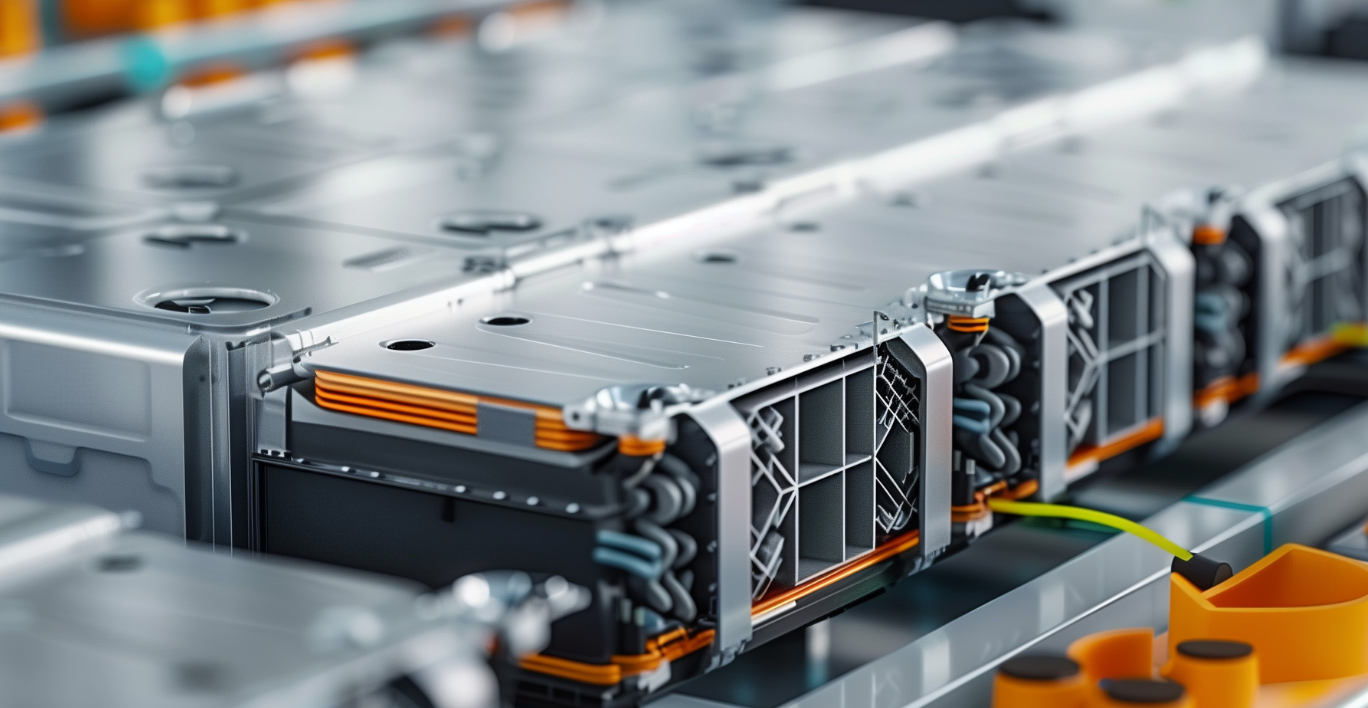

Electric Vehicle (EV) Batteries

Bonds battery cells to carriers and other structural components; used in thermal interface material (TIM) application process, potting and electrical isolation.

Electronics

Essential for assembling components, securing wires, and encapsulating parts.

Automotive

Used for sealing, bonding, and assembling vehicle parts, such as car panels