Assembly solutions built for one product are expensive and can’t grow with a company as products evolve and change. At ATS Industrial Automation, we believe assembly systems should be modular and flexible to support multiple products to maximize utilization and capital investments.

With 45 years of automation and assembly experience, we deliver innovative, configurable, scalable, high-speed assembly systems designed to accommodate one or multiple products for optimal business value. Our customers can automate high-output assembly lines that exceed 1,000 parts per minute and can group two or more operations into a single station, saving floor space and costs.

1,000+

Parts Per Minute

3,000+

Assembly Systems Delivered

45

Years Automation Experience

Every high-speed assembly project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

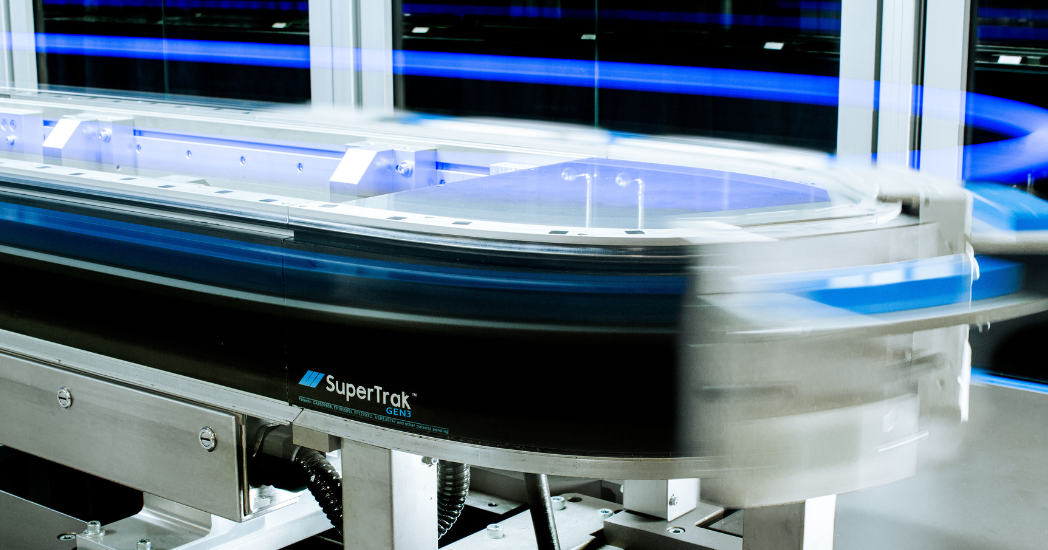

Symphoni™ Technology

Our modular, high-speed, digital assembly solution is designed to be flexible and scalable. The system combines the best assembly technologies – robotics, cam-driven synchronous machines, and power-and-free asynchronous systems – for unparalleled performance. Symphoni is digitally configurable, making adjusting profiles and running different assembly sequences on the same system easy. Our customers can run the system 24/7 to assemble multiple products on the same shift.

Benefits of High-Speed Assembly

Maximize Investment

Deliver more output per CAPEX dollar and unit floor space.

Reduce Time to Market

Get products to market faster with easily reconfigured assembly modules.

Multi-Product Versatility

The system is not tied to one product, allowing companies to maintain high machine utilization as product lifecycles change.

Reduced Operating Cost

A high level of standardization minimizes the cost of spare parts, maintenance, and training.

Speed, Precision & Versatility

We design and deliver assembly systems that are configurable for a wide range of products, from simple two-piece assemblies to highly complex products with dozens of components and specialized processes. Our system scales to meet a product’s changing needs as it progresses through its life cycle – from low-volume samples to high-volume production.

Our system can be repeatedly retooled and reconfigured for new applications. This level of versatility results in higher utilization rates and higher TEEP (Total Effective Equipment Performance).

Consumer Products

From health and beauty to household products and tools, many consumer products require high speed assembly, and testing. When margins are tight, manufacturers need efficient, flexible and reliable assembly solutions that minimize defects and production downtime.

We offer a range of solutions in plastic part and electrical component assembly, interconnect completion, precision tooling, and a several material handling variations. This may include winding systems, dispensing automation and various other process equipment. With assembly rates from 0.2 – 20 seconds per part, our systems deliver high throughput with the lowest number of defects. Our machines conserve capital and space while maintaining high equipment performance.

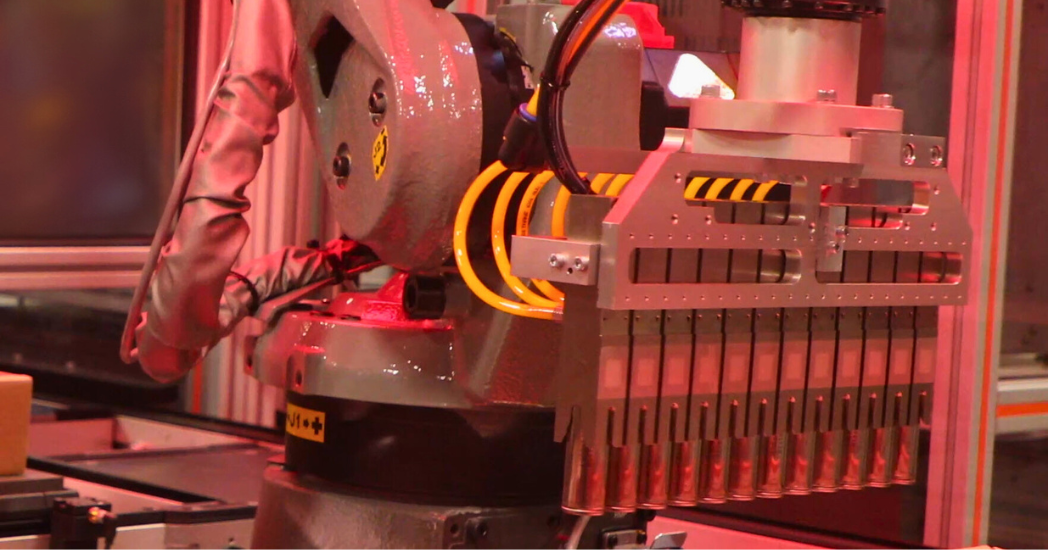

Cylindrical Cell Sorting & Assembly

Thousands of cylindrical cells are required in EV or energy storage battery packs. During the assembly process, these cells must be tested and sorted by cell voltage to ensure battery performance. Our cylindrical cell test and sort systems are compact at under 1,200 sq ft and can process a high volume of cells. With production overall equipment effectiveness (OEE) levels of over 90%, our systems are both robust and efficient to support today’s cell assembly demands.