Hydrogen Electrolyzer production involves using electricity to split water into hydrogen and oxygen through a process called electrolysis. This is essentially the reverse of a fuel cell, which combines hydrogen and oxygen to produce electricity, with water as a byproduct. An electrolyzer subjects water to an electrical current, causing it to break down into its constituent elements. The resulting hydrogen gas can be used in hydrogen fuel cells for electric vehicles (EVs), backup power generation, or other energy storage applications.

One of the primary challenges manufacturers face in hydrogen electrolyzer production is maximizing the amount of hydrogen produced per kilowatt of electricity consumed. They must optimize the electrolyzer to generate the highest amount of hydrogen from the electrical energy input. The quality of materials used, precision of the assembly process, and control of operational parameters all play a crucial role in optimizing the electrolyzer. Manufacturers continually refine their devices to enhance their efficiency and make hydrogen production more sustainable.

Hydrogen Electrolyzer Challenges

Handling hydrogen carefully to avoid leaks, which pose risks to operators and the environment.

Not having enough personnel with extensive knowledge in manufacturing electrolyzers.

Optimizing the amount of electricity required to produce hydrogen effectively.

Establishing a standardized framework to evaluate electrolyzer performance and hydrogen output.

Every automation project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

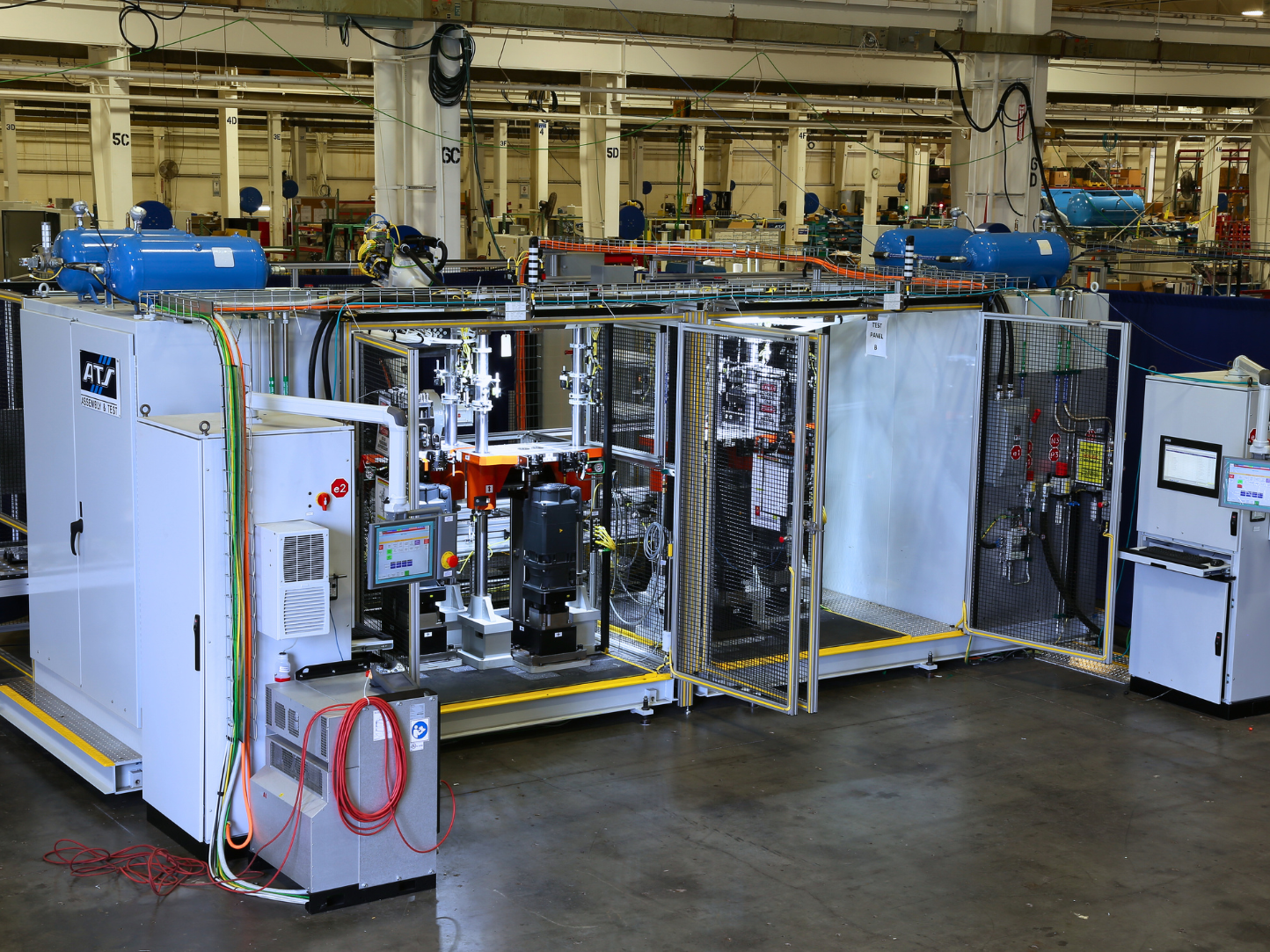

Partnering with our customers, develop processes and simultaneously engineer systems for hydrogen electrolyzer production

Custom Connectors

Design robust circuits to ensure reliable electrical connections during assembly and testing, minimizing the risk of disconnections or electrical arcing.

Proof of Principle Tests

Validate the feasibility of the assembly processes through proof of principle studies. This helps identify potential issues and refine processes before full-scale automation.

Design for Manufacturability and Assembly (DFMA)

Optimize products and processes through DFMA principles. This involves refining manual workflows for automation, driving a high-quality final product.

Testing & Validation

Conduct tests throughout assembly, including functional, leak, and stress tests, plus quality inspections. This verifies all electrolyzer equipment performs as intended.

Customer Benefits

Quality Control

Advanced vision systems and rigorous automated inspection technologies, so each electrolyzer meets quality standards.

Flexible Systems

Scalable assembly and testing solutions let manufacturers easily transition to high-volume production without compromising quality or efficiency.

Global Footprint

Our international presence supports manufacturers around the world, giving them the support they need regardless of their location.

Experience with Large Products

The precise handling of substantial, complex products, such as EV battery packs, ensures all electrolyzers are built to the highest standards.