Imagine having a virtual replica of an entire production line to visualize, simulate, and optimize each process step and conveyance before power-on. System twins can bring this vision to life, offering manufacturers a revolutionary way to reduce downtime and achieve unparalleled precision.

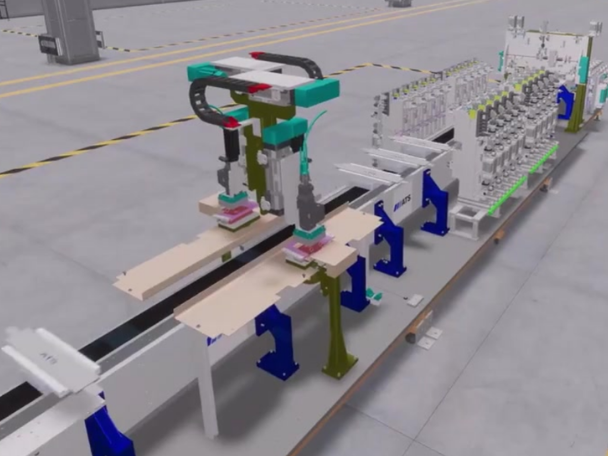

System twins are advanced virtual representations of entire manufacturing systems. They provide a comprehensive digital model that mimics the physical attributes and behaviors of machines, robots, software, and other components integrated within a manufacturing line. System twins also enable remote monitoring and diagnostics of machines so experts can diagnose and potentially resolve issues, even if they’re not physically present.

Digital Twin Technology Helps

Optimize production workflows through a virtual representation of the entire manufacturing system.

Integrate machines, robots, and all software systems into a cohesive virtual system.

Reduce downtime by simulating and predicting ongoing maintenance needs.

Optimize process throughput by providing the basis for iterative problem-solving simulations to identify and improve bottlenecks.

Enhance training, giving personnel critical skills in a virtual, risk-free setting.

Facilitate remote monitoring and diagnostics so leaders can identify and resolve issues from any location.

Every digitalization project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Implementing a system twin early on helps team leaders save critical time and costs by potentially catching missed mechanical or electrical components necessary for automated control. Our approach helps OEM leaders bring their systems one step closer to becoming a digital factory.

Virtualization of Machines

The process begins by creating models that mimic physical attributes and behaviors of individual machines. ATS can retrofit or add more product types that can be tested up-front, reducing integration time and shutdowns.

System-Level Virtualization

The next step is to create a virtual system that encompasses the manufacturing line’s full scope, including interactions between machines, robots, and all software.

Virtual Commissioning

Once the virtual system is connected to its real-world counterpart, teams can implement early testing and debugging to reduce errors. Pressure testing also ensures seldom-used functions work correctly.

Simulation & Testing

After commissioning, operators can use the virtual system to simulate various scenarios and identify potential issues before physically building the system.

Benefits of System Twins

Enhanced Understanding & Management

System twins virtually represent the entire system, allowing manufacturers and their automation partners to better manage complex processes and coordinate across multiple teams and locations.

Predictive Maintenance

System twins can simulate and forecast maintenance needs to minimize downtime and improve manufacturing productivity.

Process Optimization

Virtualizing manufacturing workflows helps enhance processes with real-time data and simulations, which identify and address production bottlenecks.

Training & Skill Development

System twins can offer virtual training environments so employees can safely hone critical skills.

Remote Monitoring & Diagnostics

System twins let experts use remote monitoring to diagnose and resolve issues from anywhere.

System Sandbox

This lets engineers experiment with different scenarios and adjust a copy of the system without disrupting operations.