Take fuel cell assembly beyond lab concepts and manual processes. We help you refine your fuel cell designs into manufacturable products that can scale. Our extensive automation and test capabilities ensure that the fuel cell mechatronics meets performance specifications and can support various fuel cell types, including hydrogen, polymer electrolyte membrane (PEM), and solid oxide.

Customer Challenges

Scaling fuel cell systems and designs from a lab environment to automated production.

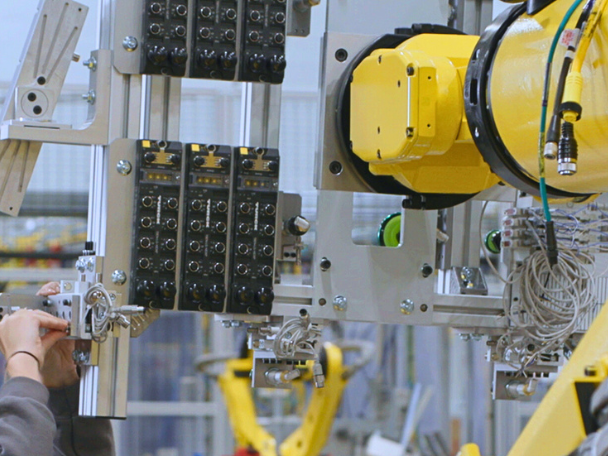

Handling and stacking fuel cells and materials while maintaining extremely tight micron tolerances.

Moving beyond the lab and a bespoke manual process that delivers repeatable automation.

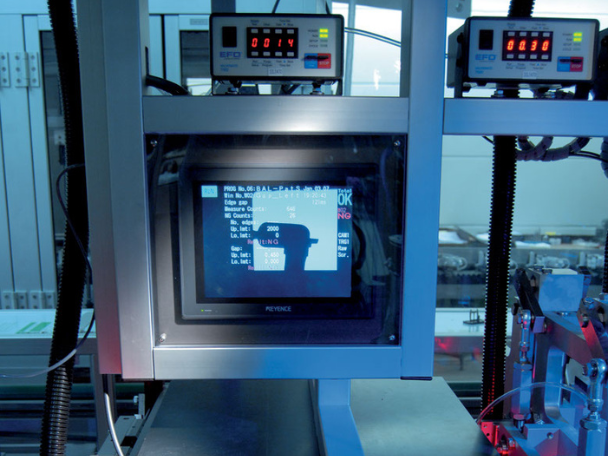

Developing a robust end-of-line test solution for both membrane and final product.

Every fuel cell project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Partnering with our customers, develop processes and simultaneously engineer systems for fuel cell assembly.

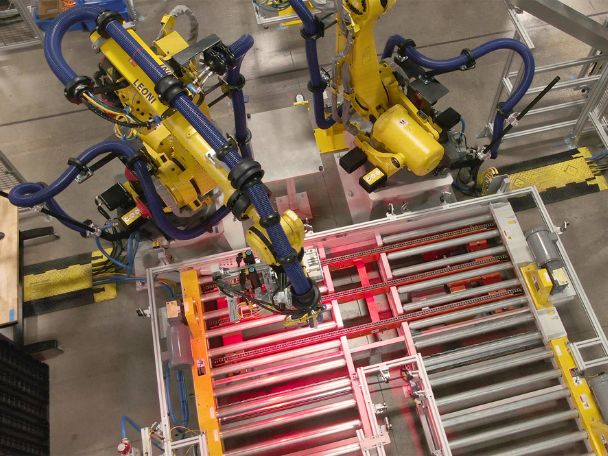

Automated Assembly

Automate the MEA stack with in-process performance testing.

Quality Control

Provide a compressive end-of-line test.

Leak Testing

Develop an intensive closed system leak test.

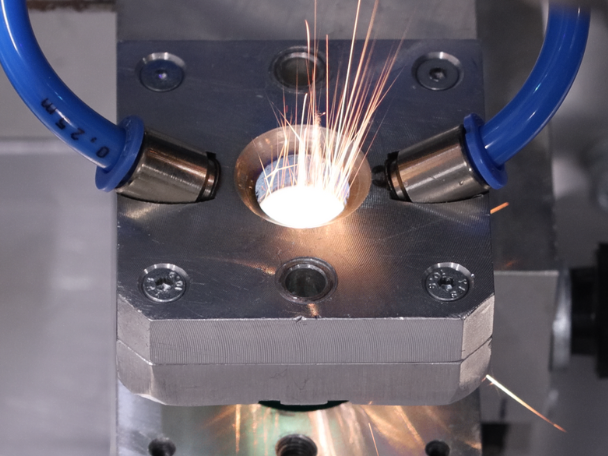

Laser Welding

Intelligent welding helps achieve a reliable zero gap while working around the intricate geometry of the fuel cell design.

Workforce Training

PIT Crew training approach that creates an efficient and effective workforce.

Customer Benefits

Customized

Design and technology tailored for your specific needs.

Efficient

Streamline process and production before build.

Scale

High throughput, consistent and repeatable automation.

Product Reliability

Identify issues early in assembly with in-process testing.