Designing more than 110 EV battery module and pack assembly and test lines, we are at the forefront of pouch, prismatic, and cylindrical battery assembly. Our proven processes, project management skills, and global reach enable customers to meet their launch dates and stay within budget. With extensive battery knowledge and comprehensive product offerings, we provide customers with a modular and flexible platform to support a range of EV configurations.

Customer Challenges

Ramping up EV battery production efficiently and cost-effectively to meet growing demand.

Finding the right global partner with expertise in moving from pilot to full-scale EV module assembly and test.

Managing variability of multiple product designs and form factors.

Optimizing testing and identifying in-process and end-of-line tests for battery modules.

Training employees on how to maintain new technology and equipment.

Every EV Module project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Partnering with our customers, we simultaneously engineer to develop high-speed cell management of tab formation, stacking, stringing, and module configuration.

Digital Engineering

Digital twin engineering to debug and validate the system virtually before building.

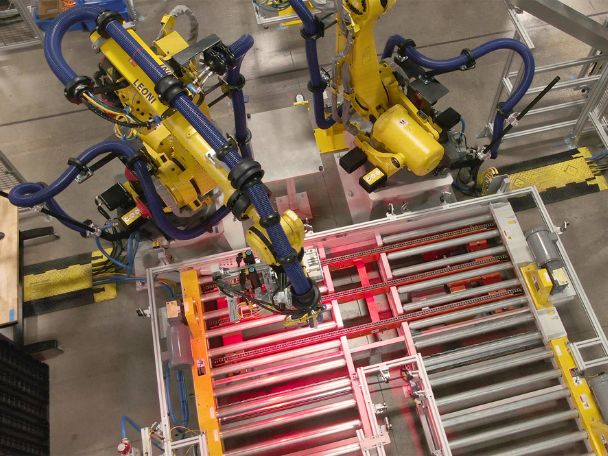

Handling & Assembly

Precise cell handling, sorting, and assembly into the battery module stacks using ATS SuperTrak CONVEYANCE™ Platform.

Monitor & Trace

Illuminate™ Manufacturing Intelligence to monitor and trace cells as it moves through the assembly process and into final vehicles.

Robust Testing

Flexible Test Executive Suite that enables scale across module configuration.

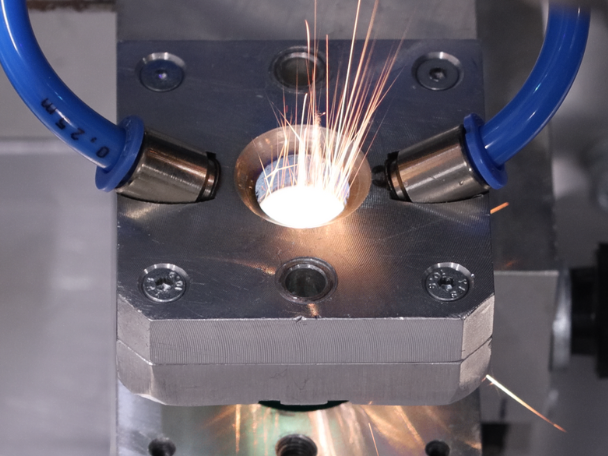

Laser Welding

Intelligent laser welding to achieve a reliable zero gap.

Workforce Training

PIT crew training approach that creates an efficient and effective workforce.

Customer Benefits

Speed to Market

Shorten the time frame to produce sellable products.

Scale

High-throughput, consistent and repeatable assembly through automation.

In Process Testing

Validate assembly steps as it moves through the processes.

Optimized Square Footage

Do more in a smaller space.

Modularity

Extend the value of CapEx investments.

“ATS Industrial Automation is critical in enabling us for battery assembly and exponential volume.”

VP of Global Manufacturing & Engineering,

Large North American Automotive OEM