An electric rotor, also called an eRotor, is a critical component in electric vehicle (EV) powertrains, rotating inside the electric motor (eMotor) to convert electrical energy into mechanical power to drive the vehicle. It works with other parts inside the eMotor to ensure the vehicle operates smoothly. Inefficiencies in the eRotor or other powertrain components can impact the vehicle’s overall performance. Advanced testing and automated capabilities are critical factors in successful eRotor assembly at scale.

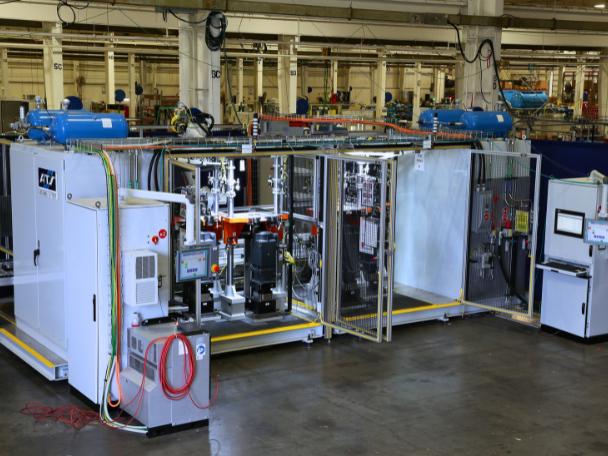

With more than 30 years of experience in the automotive industry, ATS Industrial Automation provides innovative solutions for complex manufacturing processes. State-of-the-art facilities and advanced testing capabilities ensure manufacturers can assemble each eRotor with precision and test rigorously to meet the highest standards—ensuring vehicle safety and quality.

Customer Challenges

Magnetization Issues: The magnetized nature of the eRotor can cause complications during assembly, requiring careful handling to prevent misalignment and correctly integrate with other components.

Heating Challenges: It’s crucial to manage heat generation during assembly and across the eRotor to avoid thermal stress and potential damage.

Cooling Requirements: It can be complex to design and integrate effective cooling systems into the assembly process to maintain the eRotor’s performance and longevity.

Precision Engineering: It’s difficult to achieve the high precision required for eRotor assembly to ensure optimal performance, especially when dealing with tight tolerances and intricate designs.

Integration with Other Components: Smoothly assembling the eRotor with other parts in the eMotor requires precise alignment and compatibility.

Every eRotor project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

30

Years of Automotive Automation Experience.

110+

Battery Production Lines.

3000+

Assembly Systems Delivered.

Our Approach

ATS uses state-of-the-art automation technologies for a precise and efficient assembly process, minimizing human error and enhancing the quality of the eRotors.

Comprehensive Testing

Our rigorous testing protocols ensure each eRotor meets the highest standards. This includes thermal, mechanical, and electrical testing to identify and address any potential issues early.

Customization & Flexibility

We offer flexible solutions tailored to each manufacturer’s needs. This approach allows us to provide options that best fit the customer’s production goals.

Digital Engineering

ATS uses digital twins to virtually validate the entire system’s performance before it’s physically built, saving manufacturers crucial time and expenses.

Customer Benefits

Optimized Footprint

A modular approach supports multiple eRotor configurations, so manufacturers can easily adjust workflows based on strategic goals or demand.

Faster Cycle Times

Manufacturing teams can easily scale from low cycle to high-volume production using automation.

Efficient Assembly

An experienced partner helps manufacturers implement a design for manufacturing (DFM) approach, streamlining workflows and identifying potential production issues before assembly begins. Digital tools can also support this proactive work, saving leaders critical time and costs.

Customer Network Connectivity

Teams can connect to manufacturing execution systems (MES) to better manage parts, quality control, and traceability.