Web handling is the process of managing and controlling continuous flexible materials as they move through various stages of manufacturing and processing. This involves the precise control of tension, alignment, and speed to ensure materials—such as metal, film, or foil— are handled efficiently without causing damage.

Automation experts offer advanced solutions in automated web handling that ensure the meticulous control of materials. These capabilities include high-accuracy tension control systems, web guiding systems, and automated splicing and rewinding technologies. By implementing these sophisticated methods, manufacturers can achieve higher productivity, reduce waste, and improve product quality.

Web Handling Challenges

Maintaining consistent tension throughout the process to prevent material defects.

Precisely aligning the web to avoid misalignment issues that can lead to product flaws.

Managing different material properties, such as thickness and elasticity, which can affect processing.

Controlling speed variations to prevent stretching or breaking the web.

Addressing issues related to splicing and rewinding, which can interrupt manufacturing.

Minimizing waste and optimizing material usage to enhance production efficiency.

Every automation project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Benefits of Web Handling

Tension Control

Advanced tension control systems drive steady material handling, improving product quality and smoothing operations.

High Precision

Precise web guiding systems maintain alignment and enhance overall efficiency.

Efficiency & Speed

Automated splicing and rewinding technologies minimize holdups, increasing productivity.

Applications of Web Handling

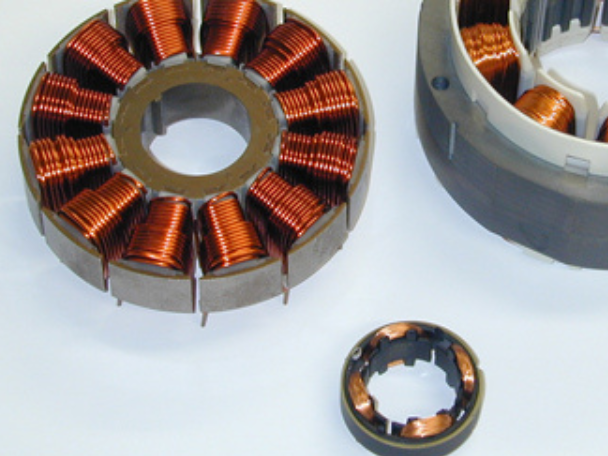

Stators

Handling materials used in the manufacturing of stators for electric motors, ensuring precision and quality.

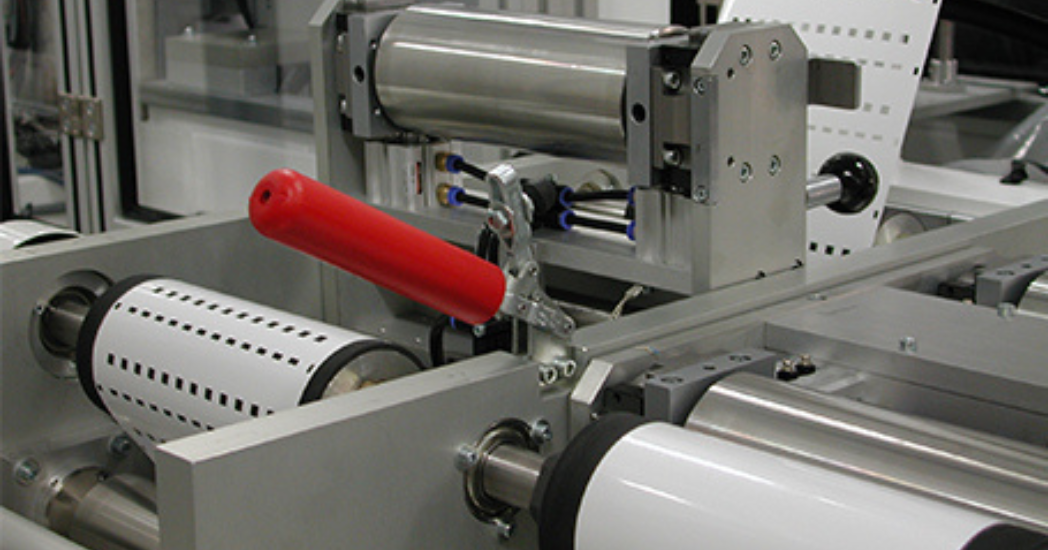

Label Application

Facilitating exact placement of labels on various products.

Winders

Managing the winding of paper, film, or foil onto rolls.

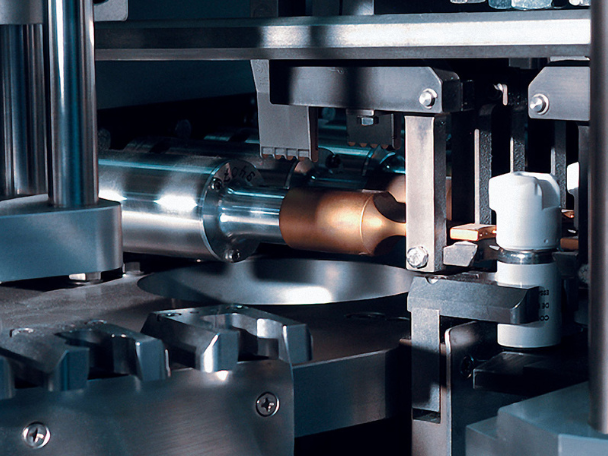

Die Cutting

High-precision trimming of parts from continuous web materials.

Web Handling Processes

Web handling systems are integrated based on the processing requirements of each material. ATS has incorporated several types of procedures into our automated web handling equipment, including:

- High-accuracy laser processing

- Marking

- Ablation

- Cutting

- Slitting

- Lamination

- Steering

- Slot-die coating

- Dispensing

- Vision inspection

- Cutting and punching

- Closed loop process controls

- Auto-splice

- Multiple tension zones

- Part tracking

- Excising/singulation

- Indexed and continuous web feed