Envision a process where every component of an automobile fits together seamlessly, ensuring optimal performance and longevity. This is the value laser line profilometry brings. A cutting-edge technique that measures the surface of objects with incredible precision, profilometry is critical, since even the slightest irregularity can lead to significant issues down the line. By employing laser line profilers, manufacturers can take non-contact, complete surface measurements to detect and rectify these imperfections early in production.

Profilometry is a vital method that drives excellence in automotive manufacturing. It enhances the quality and reliability of vehicle components, leading to fewer part defects and perhaps fewer recalls. Profilometry analysis also provides detailed insights into the manufacturing process, driving continuous improvement.

Proof of principle (POP) studies demonstrate the effectiveness of profilometry in real-world applications. One leading automotive manufacturer recently used this method to identify quality issues with parts while resolving key production challenges. This use case underscores the important role of profilometry in modern manufacturing.

Optimizing Automotive Assembly: Profilometry Use Case

A manufacturer faced significant challenges in ensuring the quality of its battery components. The customer needed to quickly detect irregularities and defects on part surfaces to maintain their reputation, avoid costly recalls, and minimize rework.

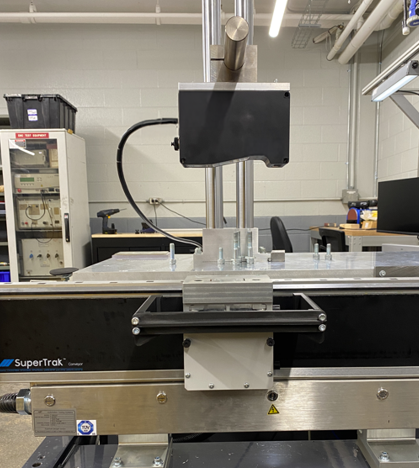

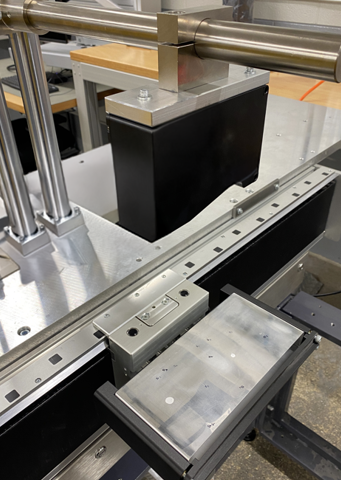

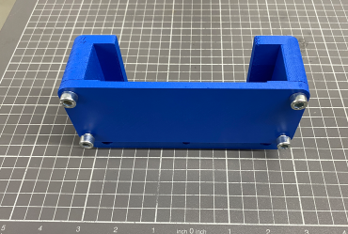

Leveraging extensive capabilities in manufacturing process optimization, automation experts at ATS created a proof of principle study with profilometry to develop a solution that addressed the customer’s challenges. By setting up a Supertrak™ CONVEYANCE cell with 3D-printed prototyped part nests and rigorously testing several profiler configurations, the team worked to determine the real-world effectiveness of using this technology to precisely detect surface deviations.

Innovative Solutions for Automotive Assembly Challenges

To help address the customer’s challenge of identifying surface irregularities and defects in the components, ATS experts implemented a comprehensive approach to the study. Using a surface profilometer and the prototype part handling system, they prepared various representative defects and captured detailed measurements with multiple laser profiler configurations. The team also used a confocal “reference” system from the ATS Innovation Center to understand detection capabilities and define the optimal selection and arrangement of laser profiler systems. This complete approach ensured inspections could capture the full range of potential defects, ultimately enhancing the quality of the battery.

While developing this solution, the ATS team encountered several challenges. One significant issue was optimizing the vision solution to effectively capture data from all battery surfaces—while satisfying high throughput requirements with the Supertrak™ system. The laser profilers also needed to be set up to inspect a variety of metal finishes and non-metal surfaces, based on the cell configuration and its surface.

Based on these learnings, the team defined the final design, selecting the right number of device models and the most suitable configuration and scan parameters to satisfy the customer’s requirements and ensure high-value battery cells were accurately inspected.

Reducing Defects in Automotive Assembly: The Impact of Profilometry

The POP study yielded significant insights, demonstrating how a laser profiler-based solution could perform a complete surface inspection of battery cells and capture minute defects for the customer. What’s more, ATS experts gained more insights about the full capabilities that different laser line profiler systems provide—enabling them to apply these findings to other projects in the future.

The study was also instrumental in providing empirical evidence that profilometry analysis could identify and address issues early, leading to continuous improvement in production. By optimizing manufacturing workflows, the customer could produce higher-quality battery components with greater efficiency, saving critical time and costs.

Every profilometry project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Oleksiy Boiko

Technical Lead - Vision

ATS Industrial Automation

Oleksiy helps companies across numerous industries with planning and deploying innovative vision systems. With over 15 years of experience as a Vision Designer, Oleksiy works with customers to optimize the visual and technical design of their branding and user interfaces to drive engagement and operational efficiency.