Scaling up manufacturing production lines is a complex process that requires careful planning and execution. The pressure to meet growing demand can push manufacturers to accelerate timelines, but blindly rushing the process often leads to costly delays and errors. Manufacturers can minimize setbacks, ensure smoother scale-ups, and meet their market goals by adopting a strategic approach and best practices.

To avoid common pitfalls and minimize delays when adding new production lines, manufacturers can adopt several strategies:

1. Incrementally Rollout Lines

Manufacturers face pressure to deploy multiple manufacturing lines at once or in quick succession to meet consumer demand. However, rushing the rollout of new lines leaves little time for adjustment and fine-tuning of processes. Manufacturers risk replicating mistakes across lines, affecting financial performance and end consumer satisfaction.

Adopting a staged or tiered rollout strategy allows teams to work through potential issues and make improvements between deployments. Manufacturing leaders should set realistic timelines that allow for adjustments and refinements as early lines are brought online. This ensures that each line can be optimized, building the initial OEE of each subsequent line and reducing the risk of cascading problems that could delay the entire program.

2. Establish Change Management Processes

Large-scale projects and new products with accelerated to-market schedules, such as electric vehicle (EV) batteries, often include evolving requirements and frequent change requests. These can easily disrupt timelines, especially when companies and their automation partners need a structured process for evaluating and implementing changes.

To manage change requests effectively, manufacturers should establish a robust change management process. This involves dedicating a team to assess proposed changes, determining the impact on designs or manufacturing processes, estimating costs, and understanding how changes affect the project schedule. Discuss and evaluate change requests with your automation partners to align expectations. Can your partner meet the change request within their existing contract? Or will new resources need to be added? Clear processes will help manufacturers navigate modifications and mitigate any potential disruptions to the project schedule.

3. Define Ownership

In newer, high-tech areas, such as battery assembly lines, responsibilities around process ownership often become blurred, especially when product designs are still evolving. For example, is the auto manufacturer, the component supplier, or the automation partner responsible for the laser welding process in battery pack production? Are test system parameters defined, and understood by all stakeholders?

To prevent confusion, be clear with all parties on who owns processes and sub-processes early in the project. Defined ownership reduces friction between stakeholders, minimizes time-consuming disputes, and ensures smoother coordination, which is vital to maintaining the project schedule.

4. Allocate Resources

Once the product manufacturing process is established, development engineering teams move on to the next project, leaving a smaller engineering team to focus on scaling. However, leveling up from a small test manufacturing line to full-scale production comes with new challenges.

Manufacturers need to ensure they have the right people and resources in place. This includes project management, engineering application specialists, material or supply chain manager, HR, legal, etc. Having a plan on what critical skills and resources are needed, and a well-rounded team ensures that challenges like change requests or sourcing issues can be quickly assessed and resolved, keeping the scale-up process on schedule.

5. Use of Modular Assembly Designs vs Custom Designs

Many delays can also be traced back to a lack of standardized designs and modular assembly approaches. While custom (or bespoke) designs represent opportunities for efficient solutions tailored to your specific needs; they are more time-consuming as compared to standardized modules and components.

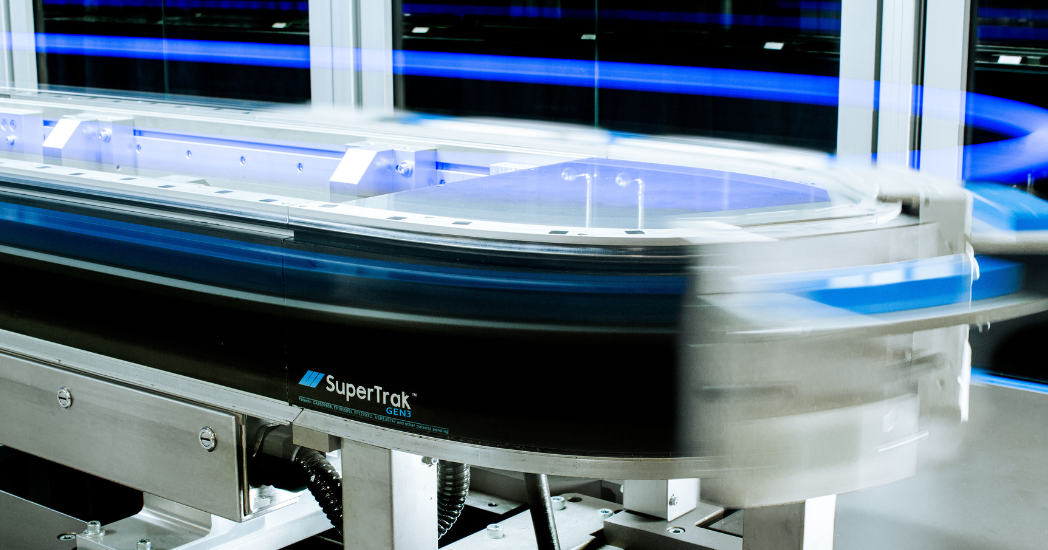

When possible, implement modular and proven assembly equipment and digital technology, such as the SuperTrak CONVEYANCE™ Platform with SYMPHONI™ technology, which makes it easier to scale up. Modular designs enable the reuse of proven solutions and minimize the time spent designing from scratch for each new project.

Modular equipment can also be tailored and adapted to process changes or new product designs where appropriately selected, giving manufacturers greater agility and utilization to ensure that products launch on time.

6. Be Flexible and Transparent

When scaling up a new manufacturing line, unexpected delays can still occur, even with thorough planning. Open communication with all parties about timelines and potential challenges is crucial for managing unexpected situations, stakeholder expectations, and avoiding unrealistic targets. Remain adaptable and anticipate obstacles—such as supply chain disruptions, defective parts, equipment malfunctions, or changing requirements.

Maintaining transparency between internal teams and external partners ensures that everyone remains aligned and can respond quickly to challenges. By building contingency plans and fostering open dialogue, manufacturers can address issues promptly, minimizing their impact and maintaining production timelines; while end-users can openly communicate timeline readiness of their facilities and production needs.

7. Production Ramp Up & Support

Many team members are well prepared to operate preexisting equipment in their facilities, but new equipment represents a learning curve based on the specific needs of that system. A new manufacturing line will likely have new processes, components, and maintenance needs compared to other equipment in the same facility. Utilizing tools like Illuminate™ Manufacturing Intelligence can help understand the equipment by keeping the team informed on real-time status, trend performance, and even help identify areas for future equipment upgrades.

Including the OEM equipment supplier, either through an extended support team on-site or on retention for emergencies, maintains continuity of that knowledge from the machine designer and builder that allows for smoother ramp-up of production, faster recovery, and the ability to provide continuous training to the production team to become experts themselves. Spare parts should always be considered to minimize the chance of failure stopping production.

A Balanced Approach

Scaling manufacturing assembly lines requires balancing ambitious goals with operational discipline and a clear plan. Manufacturers can minimize delays and deliver consistent results by taking a strategic, phased approach and ensuring strong support structures. Remaining flexible, focusing on clear communication, and empowering teams with the right resources are essential to a successful scale-up. With careful planning, responsive engagement, and continuous improvement, manufacturers can achieve sustainable growth while navigating the complexities of scaling up.

Rob Turton

Program Manager

ATS Industrial Automation

Rob has over 20 years of experience helping companies across numerous industries automate their assembly and testing lines. Rob specializes in managing large-scale programs and works with customers to optimize production lines and drive operational efficiency.