Barcode production, grading, and reading are essential components in modern manufacturing and logistics. This process involves creating unique barcodes that can be printed on products, packaging, or labels. The codes store information such as product details, making it easier for teams to track and manage inventory.

Barcode grading ensures the printed barcodes meet quality standards and can be correctly read by scanners. Grading involves evaluating the manufacturing barcode’s print quality, contrast, and readability to confirm it meets industry requirements.

Barcode reading is the process of scanning and interpreting encoded information. This is crucial in various industries, including retail, healthcare, and manufacturing, where accurate and efficient data capture is essential for successful operations and end results.

Manufacturing Barcode Challenges

Ensuring high-quality barcode production to avoid issues with readability and scanning accuracy.

Managing the reliability of barcode grading to consistently meet industry standards.

Overcoming difficulties in scanning barcodes due to poor print quality or damaged labels.

Integrating barcode systems with existing production and inventory management processes.

Identifying advanced technology to handle various barcode types and applications.

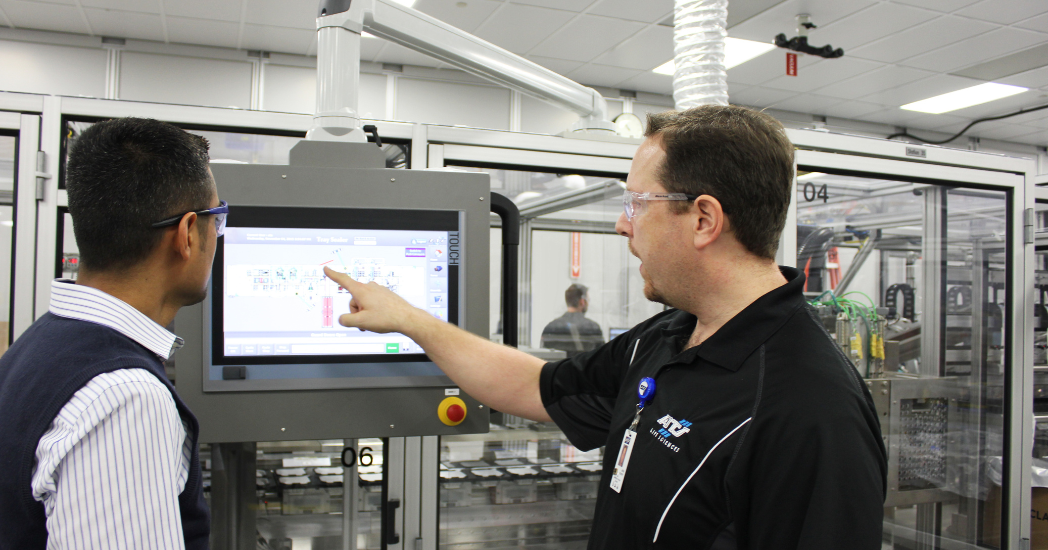

Every automation project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Benefits of Barcode Production

Advanced Technology Integration

ATS experts can integrate any industry barcode solutions, including sophisticated scanners and grading systems that fulfill industry specifications.

Improved Operational Efficiency

ATS works with any industry-leading barcode technology, enabling manufacturers to streamline operations, reduce manual errors, and refine overall productivity.

Comprehensive Solutions

We offer expertise in integrating barcode production, grading, and reading—seamlessly implementing barcode technologies with customers’ existing assembly and inventory workflows.

Expert Support & Collaboration

ATS experts support and collaborate with customers to tailor barcode solutions to their unique needs, optimizing performance.

Manufacturing Barcode Applications

Inventory Tracking

Barcodes track raw materials, components, and final products, ensuring correct inventory levels and efficient stock management.

Quality Control

Barcodes help monitor and record quality checks at various stages of assembly, so products meet market requirements.

Traceability

Barcodes trace products throughout assembly, from raw materials to finished goods. This enables the quick identification and resolution of issues.

Production Line Efficiency

Barcodes streamline the manufacturing process by automating data capture and reducing manual entry errors, leading to improved productivity.

Shipping and Logistics

Barcodes facilitate accurate, efficient tracking of products during shipping and logistics, reducing the risk of errors and ensuring timely delivery.

Barcode Production

Barcode production is critical in manufacturing. These codes store critical product information including batch numbers and expiration dates, helping drive successful, faster inventory management.

However, there are several challenges in this process. High-quality prints are crucial, as poor print quality can lead to unreadable codes and cause disruptions in the supply chain. Maintaining consistency in manufacturing barcodes across batches and materials can also be difficult, leading to potential errors and costly delays.

To address these obstacles, ATS integrates advanced technology with rigorous quality assurance measures, including high-resolution printers and special inks that produce clear, durable barcodes. By leveraging state-of-the-art technologies, these barcode production solutions enhance operational efficiency for manufacturers.

Barcode Grading

Barcode grading drives the quality and readability of the codes, no matter the industry. One key challenge here, however, is maintaining consistent print quality across batches and materials. Poor print quality can lead to illegible barcodes, interfering with the supply chain and the manufacturer’s ability to properly manage inventory.

To alleviate these challenges, ATS employs the industry’s most innovative grading systems that analyze the print quality, contrast, and scannability of barcodes. Using high-resolution scanners and specialized software, these systems weigh the barcodes against industry standards, so they meet required quality levels. By implementing automated grading, ATS can help manufacturers detect and rectify issues early in the production cycle, reducing the risk of unreadable product barcodes reaching end users. This approach not only refines the reliability of barcode systems but also improves assembly and inventory tracking processes.

Barcode Reading

Barcode reading is a crucial process in industries that need real-time data capture. One of the primary roadblocks in this step is making sure the barcodes are readable. This can be difficult due to poor print quality, physical damage, or environmental factors like dust and moisture. These factors can lead to misreads or failed scans, disrupting production and causing delays. Different barcode types, including 1D and 2D, add a layer of complexity.

ATS employs sophisticated barcode reading technology for high accuracy and reliability. The approach uses high-resolution scanners that can read a variety of code types and handle various environmental conditions. ATS also integrates automated systems that can quickly and correctly interpret data. These robust barcode reading solutions enhance data collection accuracy and streamline operational workflows.