20 Years of Experience Bringing Automation to Nuclear Projects

Downtime for a nuclear project can cost over a million dollars a day, and failure is not an option. Nuclear projects demand a predictable and reliable schedule that companies can plan and rely on for their plant life extension projects.

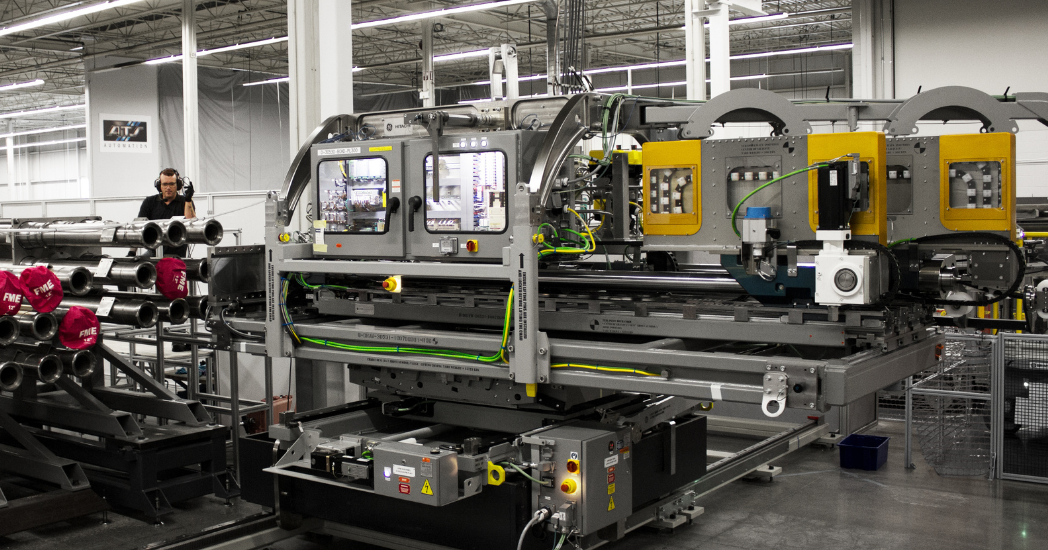

We manufacture tooling and design automation for new reactor builds, refurbishment, operations and maintenance, and decommissioning across both large-scale and small modular reactors (SMRs). Automation yields reliable and repeatable processes that teams can plan and execute across locations and shifts.

Our experienced nuclear team incorporates benchmark quality management systems that are compliant with

Every nuclear project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Refurbishment

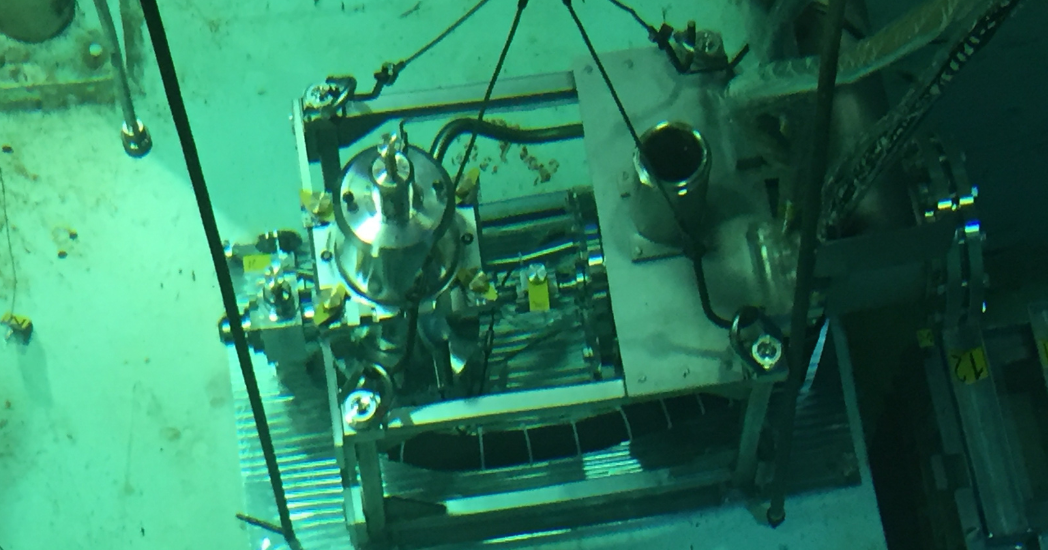

Nuclear reactor refurbishment extends the life of an energy facility by decades. Our experts have designed and constructed over 500 automated tools and remote systems that allow highly irradiated reactor internals to be safely removed and updated. Our systems help reduce worker dose exposure, providing a reliable path for reactor refurbishments that save days to schedule.

Decommissioning

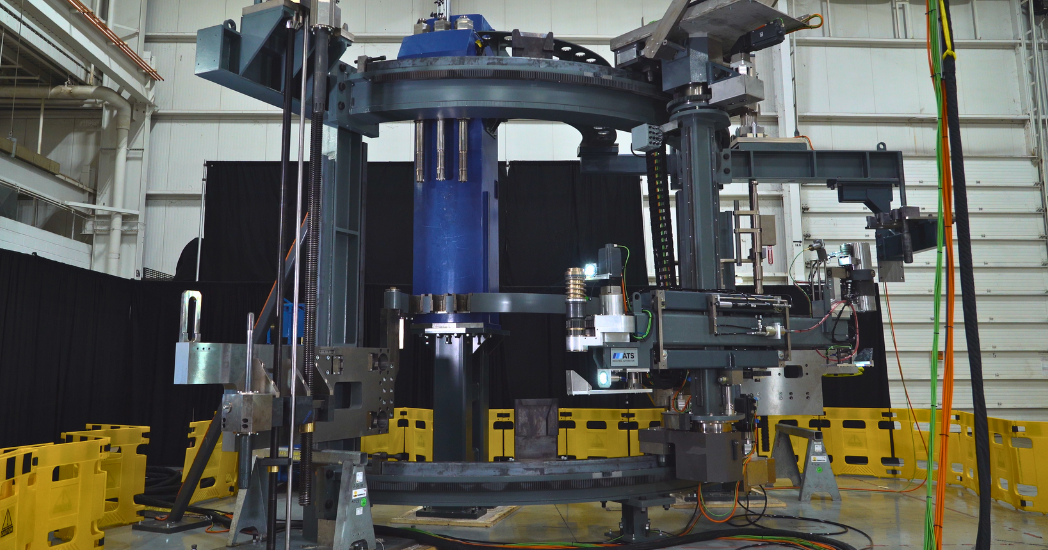

Nuclear decommissioning projects take decades and can still run over schedule and over budget. We bring high-quality automated tooling and processes to nuclear reactor pressure vessel dismantlement programs. Our proven automated solutions can help accelerate delivery, optimize nuclear waste packaging, provide a predictable schedule, and improve worker safety.

Significantly reduce downtime.

Achieve targeted uptime.

Improve efficiency targets.

Operations & Maintenance

Our nuclear team has a proven track record of improving operation efficiency and automating manual routine maintenance processes. Our solutions enable the remote visual inspection of reactor components for evaluating damage, and degradation, to verify component integrity for regulatory requirements. With remote tooling and automated delivery systems, nuclear power plants can reduce critical path activities and worker dose to provide a safe, efficient path for maintenance and inspection activities.

Small Modular Reactors

We are a design partner and provide tooling solutions used in advanced reactor development and installation including Small Module Reactors (SMRs). Using simultaneous engineering with our digital twin technology, we can test, adjust, and optimize reactor process capabilities earlier in the program, providing confidence that the performance and processes support our customers’ unique needs for nuclear maintenance.

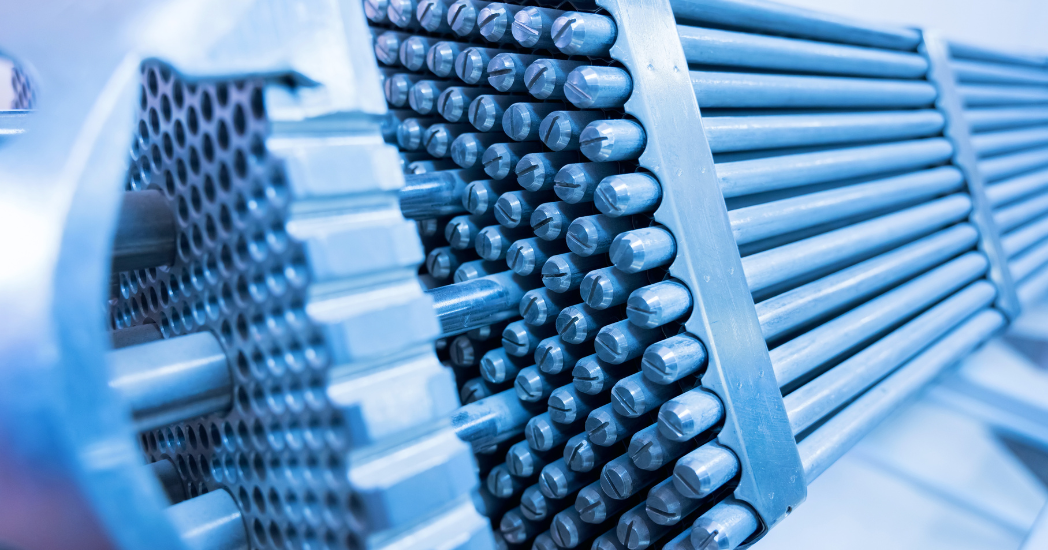

Fuel Fabrication

With more than two decades in the nuclear sector, we specialize in delivering cutting-edge automated solutions for every phase of the fuel fabrication process across a variety of reactor types. Our extensive global reach allows us to provide tailored support throughout the entire lifecycle of your fuel fabrication project.

High-Reliability Software

ATS delivers high-reliability software solutions that power some of the world’s most critical systems. Our integrated in-house offering can include software, electrical hardware, and tooling—all developed and supported internally. This means faster deployment, minimal learning curve, reduced integration risk, and a lower total cost of ownership through streamlined support and faster troubleshooting.