Nuclear reactor components and systems must operate in a wet environment. To have confidence that new tooling systems will operate as expected, they should be tested and verified in a submerged environment. Potential problems can be quickly identified and systems modified before the tooling ever enters your nuclear facility.

ATS Industrial Automation has extensive experience designing, developing, testing, and delivering automation solutions for nuclear refurbishment, decommissioning, and new reactor projects. Our North American design and submerged system testing facility features multiple pools to accommodate the testing of small and large equipment underwater. Our integrated approach provides greater flexibility for real-time system modifications and hands-on training without impacting project schedules or budgets.

Customer Challenges

Finding the right partner with large, deep water pools for testing of full-sized automation or cutting equipment.

Building and testing of automated systems within the same facility to minimize shipping.

Accessing and modifying equipment safely while performing submerged testing.

Training employees on how to install and operate equipment underwater.

Every testing project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

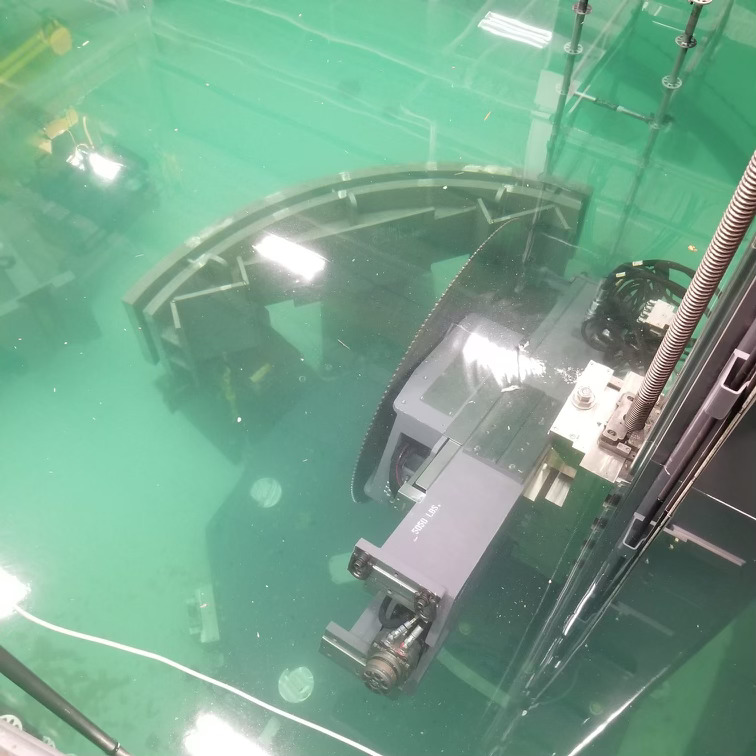

ATS Industrial Automation’s submerged system testing facility is unique in the industry. Our large, deep water pools use modular construction and can be built around the equipment. Water is pumped into the pool, simulating the actual environment, and later drained into a secondary tank. With fast water draw-down times, our design team can easily access the dry pool and make system modifications onsite without requiring cranes to move large, complex equipment. This improves overall worker safety and streamlines the testing process.

Simultaneously Test Multiple Systems

Accommodate multiple projects using a choice of underwater pools and sizes.

Simulated Production Environment

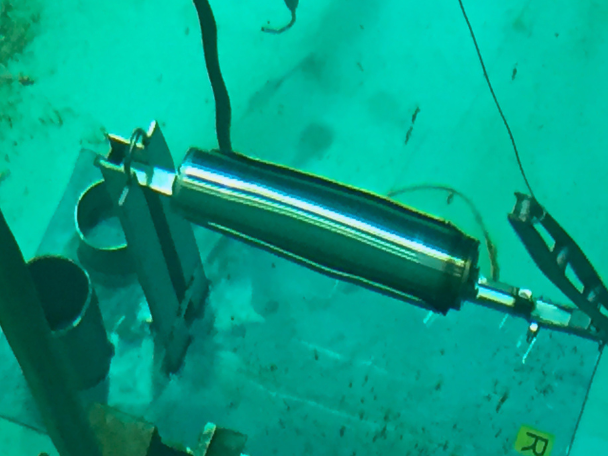

Create high fidelity mockup testing environments.

Onsite Automation & Nuclear Expertise

Leading experts in nuclear and automation onsite to optimize tooling and processes.

Hands-On Training

Comprehensive training of equipment in submerged environment replicating real life operating conditions.

Our Facility

Two Large Modular Pools

18ft (4.5m) deep in height x 28ft (8.5m) in diameter

Two Small, Recessed Pools

4ft (1.2m) deep in height x 8 ft (2.4m) in diameter.

Observation & Equipment Control Mezzanine

3-level mezzanine for multiple viewing opportunities.

90,000 sq. ft. Facility

Space for manufacturing, testing, and a training center.

Customer Benefits

Verify Underwater

Perform testing before tooling goes into the field.

Speed Development Times

Build and test in one facility.

Optimize Design

Make real-time modifications during testing.

Stay On Budget

Avoid the expense of shipping equipment to secondary facilities.

Streamline System Operation

Workforce training ensures a prepared team to install and maintain equipment.

Improved Safety

Limited crane use reduces risk to workers and testing equipment.

“We pride ourselves on being A Generation Ahead by Design… One of those needs is decommissioning, which requires the best people, planning, processes and equipment. We chose ATS to assist us because of their demonstrated nuclear industry expertise and technology, and their ability to develop a low-risk, innovative and modular solution.”

PK Chaudhary,

Holtec’s Senior Vice President of Operations.