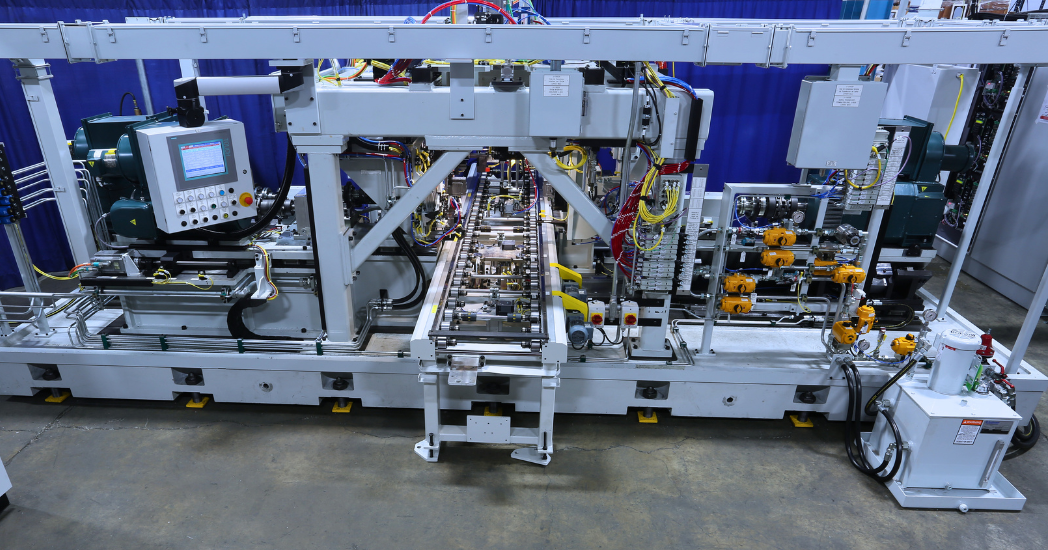

We offer state-of-the-art eDrive and transmission testing systems to validate for speed, power, torque, and performance. With 40+ years of experience supplying hundreds of powertrain and transmission test stands globally for light and heavy-duty vehicles and offroad equipment, our modular testing systems are easily customizable to support today’s rear-wheel drive (RWD), four-wheel drive (FWD), all-wheel drive (AWD), pure electric vehicles (PEV) and plug-in hybrid electric vehicle (PHEV) designs.

With complete systems for functional testing, endurance testing, NVH analysis, and more, eMobility companies can confidently deliver reliable, high-quality vehicles to the market.

Customer Challenges

Identifying testing processes, sequencing and test equipment requirements for transmission and eDrive production.

Developing a high-voltage DC power supply testing system that can accommodate changing requirements.

Ramping up transmission and eDrive production efficiently and cost-effectively.

Managing variability of multiple product designs, variations and form factors.

Every testing project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

We work with automotive and eMobility companies to establish product testing needs, methodologies and deliver complete automated test systems that are tailored to a customer’s application and high-speed assembly production requirements.

Customer Network Connectivity

Connect to Manufacturing Execution Systems (MES) to manage part, quality, and traceability.

Robust Testing Platform

Test Executive Suite is quickly configurable to testing requirements.

Monitor & Trace

Operators can access real-time production data, analytics, and reporting using Illuminate™ Manufacturing Intelligence.

3rd Party Software Integration

Set up the test parameters and data collection, and utilize your preferred software.

Customer Benefits

Higher Quality Products

Identify, remove, and fix early in the process.

Flexibility

Support for a multitude of product variations and platforms.

Scale

High-throughput, consistent and repeatable testing through automation.

eDrive & Transmission Testing Applications

eDrive Testing Systems

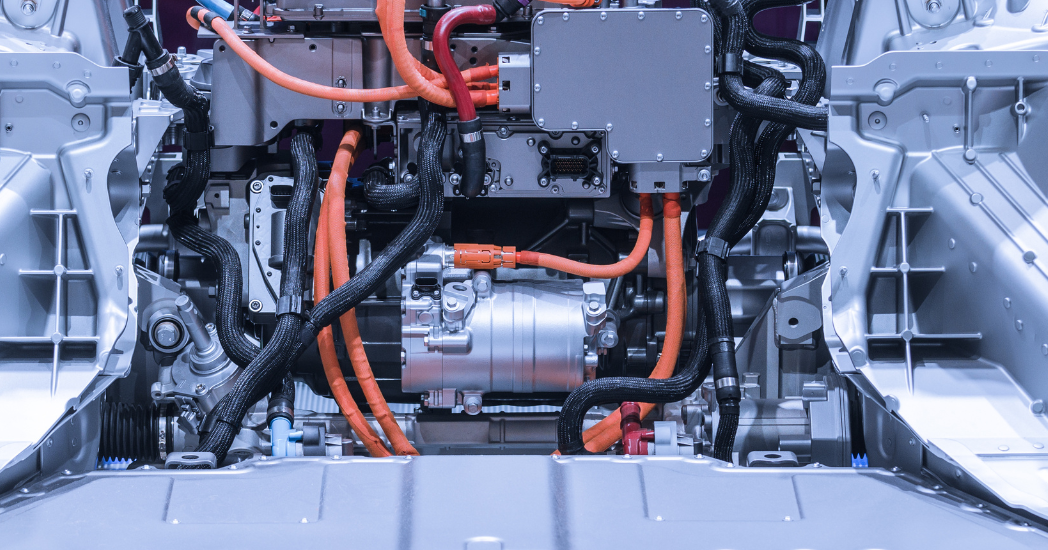

Our comprehensive eDrive testing systems for electric and hybrid vehicles measure efficiency, power output, and thermal management across varying loads and speeds. Key tests include HiPot and insulation resistance (IR) for assessing eDrive electrical safety. We simulate battery power supply conditions, providing and absorbing high-voltage DC power while precisely monitoring current throughout the test. Customers can optimize the entire EV drivetrain for extended range and reliable operation.

eDrive Assembly Testing Methods

- AC input & output motors for torque and speed control

- Flexible input and output driveline positioning

- Simulation of engine input, inertia, and speed

- Test sequences, gear shift, clutches & differentials

- Leak checks, shaft seals, torque converter, torque multiplications, lock up, oil fill & top off

- Transmission control unit interface or simulation

- Data acquisition testing

- NVH analysis

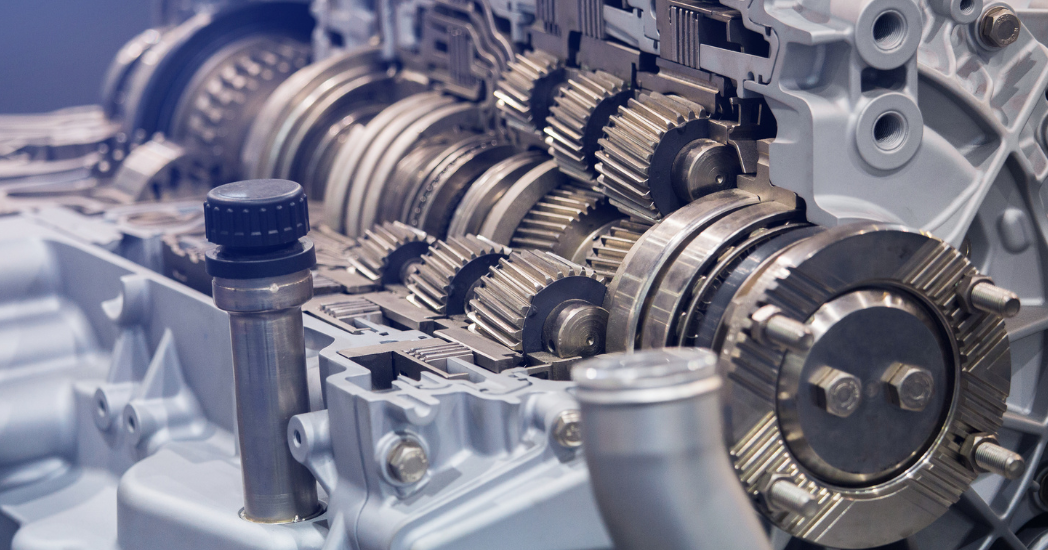

Transmission Testing Systems

We offer advanced transmission assembly and testing systems for new vehicle production, vehicle repairs, and warranty claims. Our production and lab-grade mesh transmission test systems guarantee industry-standard repeatability (GRR) and correlation (R²) for noise and vibration (NVH) testing of powertrain components. Our solutions include gear quality verification, torque measurement, vibration testing, and end-of-line noise checks. Designed to handle large variations in torque and speed, our stands are readily configured for single or multiple models. Other capabilities include modular designs, engineered drivelines, and integrated data acquisition for a truly comprehensive and adaptable testing solution.

Transmission Assembly Testing Methods

- AC input & output motors for torque and speed control

- Flexible input and output driveline positioning

- Simulation of engine input, inertia, and speed

- Test sequences, gear shift, clutches & differentials

- Leak checks, shaft seals, torque converter, torque multiplications, lock up, oil fill & top off

- Transmission control unit interface or simulation

- Data acquisition testing

- NVH analysis

Reman Dynamometer Testing Systems

Dynamometer or dyno testing for traditional transmissions and eDrives measures force, torque, power and rotational speed (RPM) of an engine or eMotor. We offer modular remanufactured dynamometer testing systems ideal for areas where warranty claims and repairs are preformed to test that the engine is safe and operational before hitting the road.

Dynamometer Testing Methods

- AC input & output motors for torque and speed control

- Flexible input and output driveline positioning

- Simulation of engine input, inertia, and speed

- Test sequences, gear shift, clutches & differentials

- Leak checks, shaft seals, torque converter, torque multiplications, lock up, oil fill & top off

- Transmission control unit interface or simulation

- Data acquisition testing

- NVH analysis