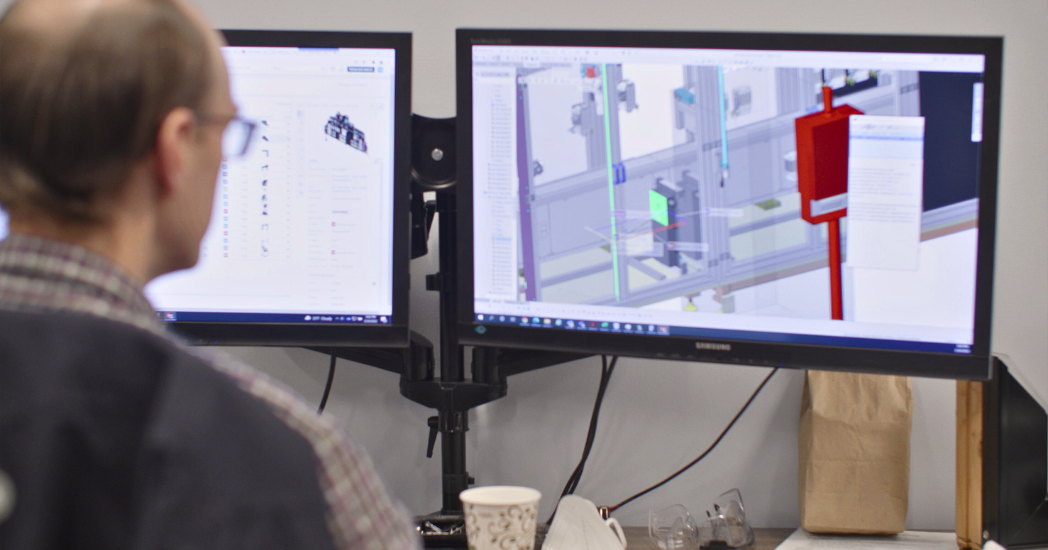

Imagine being able to test and optimize product designs and manufacturing processes before they even reach the production floor. Digital twin process simulations, which ATS has leveraged for over 10 years, help customers do just that.

By using a digital twin’s virtual production floor, teams can gain critical insights into their assembly solution’s final fit and function. Digital twin simulations also allow teams to see how changes to the product or automation design will affect the performance of the production line. By simulating designs digitally, teams can validate and refine their processes before implementing a build.

Process Simulation Helps

Measure and optimize performance by virtually simulating different operational use cases.

Mitigate risk and save resources by identifying and correcting potential issues early.

Accelerate line delivery by speeding up the design and testing of new machines through virtual simulations.

Create system sandboxes to experiment with simulated scenarios until achieving the desired outcome virtually.

Improve system integration testing so project leads can test software systems well before Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT).

Every digitalization project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Benefits of Digital Twin Simulations

Measure & Optimize Performance

Manufacturers can see how design iterations will impact performance through virtual simulations of different use cases.

Mitigate Risk & Save Resources

Simulation helps teams eliminate inefficiencies by predicting performance data on a variety of operational scenarios.

Accelerate Commissioning

Simulations and digital workspaces enable teams to speed up the design and testing of new machines—and collaborate across sites.

Create System Sandboxes

System twins let engineers ‘play’ with simulated scenarios to optimize system upgrades.

Cinematization & Research

Simulation supports mechanical design by virtualizing various forces, such as traction, torsion, and collision. This ensures the mechanical design meets the required specifications and can withstand multiple operational conditions.

Robot Programming & Safety

Simulations support mechanical design by ensuring the proper positioning, mounting, and collision-free operation of robotics. This involves programming the robots and setting up safety measures to prevent accidents and ensure smooth operations.

Line Simulation

All functions are embedded in one software, allowing teams to view comprehensive process simulations of the entire production line. This helps teams optimize each line’s performance and identify potential issues or bottlenecks before they occur.