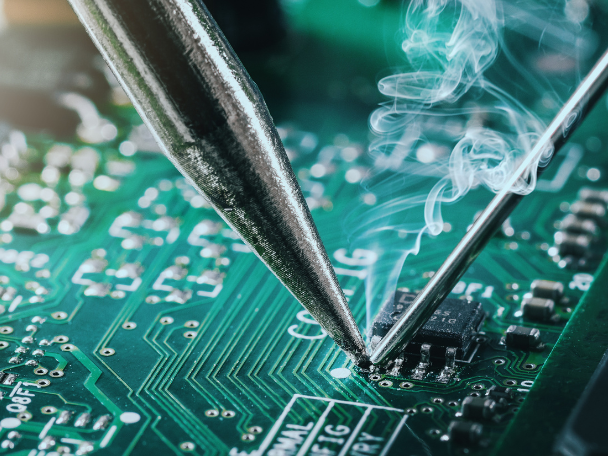

In today’s interconnected world, devices are interdependent on mechanical and electrical designs. Mechanical assemblies are increasingly being connected with electronic features — the brain of which is the printed circuit board (PCB). Automated PCB handling and soldering techniques play a vital role in ensuring these circuits are safely installed with robust electrical connections.

A strong automation partner will excel in helping manufacturing leaders employ advanced techniques for high-quality solder joints. They’ll also design their system to protect the manufacturer’s electronic assembly by adhering to best practices and industry standards set out in ANSI/ESD-S20.20. Selecting the correct soldering process enables manufacturers to comply with critical industry standards like IPC-A-610. By understanding each product’s specific requirements and utilizing precise tooling, teams can optimize these PCB loading and soldering techniques for performance and reliability.

Challenges with PCB Handling and Soldering

PCB Design Complexity: Consider design elements that would be conducive to automated processes. Manufacturers need appropriate “keep out” areas for grippers to handle the boards. They must also be mindful of traces within the PCB’s sub-layers. Some techniques, like inductive soldering, can heat up sections outside the targeted area and potentially damage the PCB.

Quantity of Solder Joints: Minimize the solder joints needed. Each joint increases the opportunities for failure.

Handling Sensitivity: PCBs often contain many parts that are sensitive to electrostatic discharge (ESD). It is imperative to ensure the automation includes ESD-safe best practices.

Surface Preparation: Ensure the surfaces to be soldered are clean and free of residue and oxides. This is crucial to achieve reliable solder joints.

Process Control: Maintaining precise control over soldering parameters, such as temperature and solder volume, prevents defects and ensures consistent quality.

Every PCB soldering project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

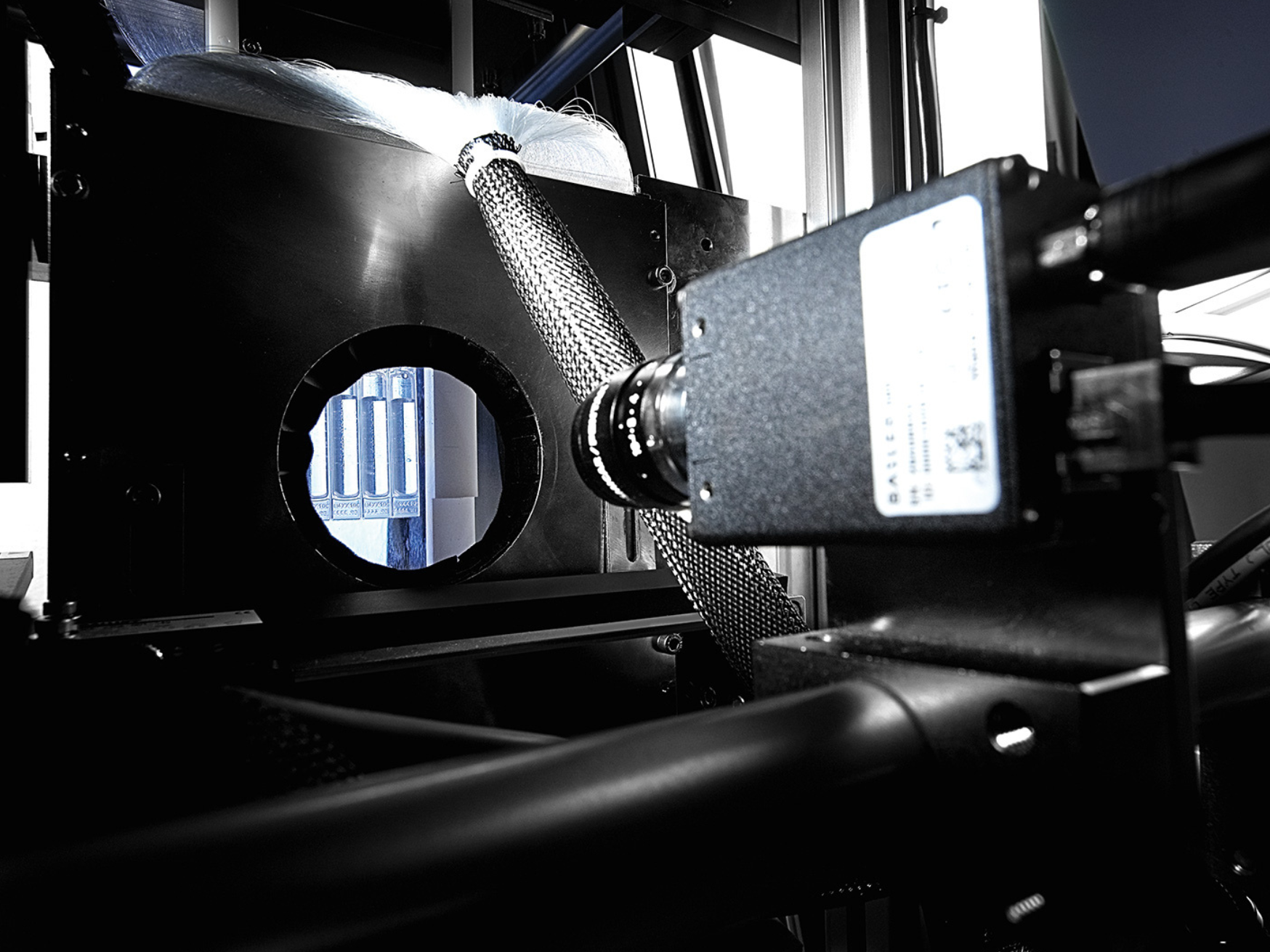

Advanced Defect Detection

Depending on the application, ATS Industrial Automation experts recommend 2D vision systems and 3D X-ray scanners to help identify defects and ensure the integrity of the solder joints.

Process Optimization

We optimize soldering efforts with precise tooling and robust process development to achieve high-quality, reliable results that meet the required specifications and cycle times.