How do you turn new ideas into tomorrow’s gigafactory in a rapidly evolving market? Whether you’re running a start-up or an established company, it takes years to turn that idea you had in the lab into a prototype, and eventually into a mass-manufacturable, high-volume product. Drawing from over 45 years of automation experience, here we share what we see as the seven stages of a product lifecycle, and key insights to help companies navigate the challenges of scaling manufacturing.

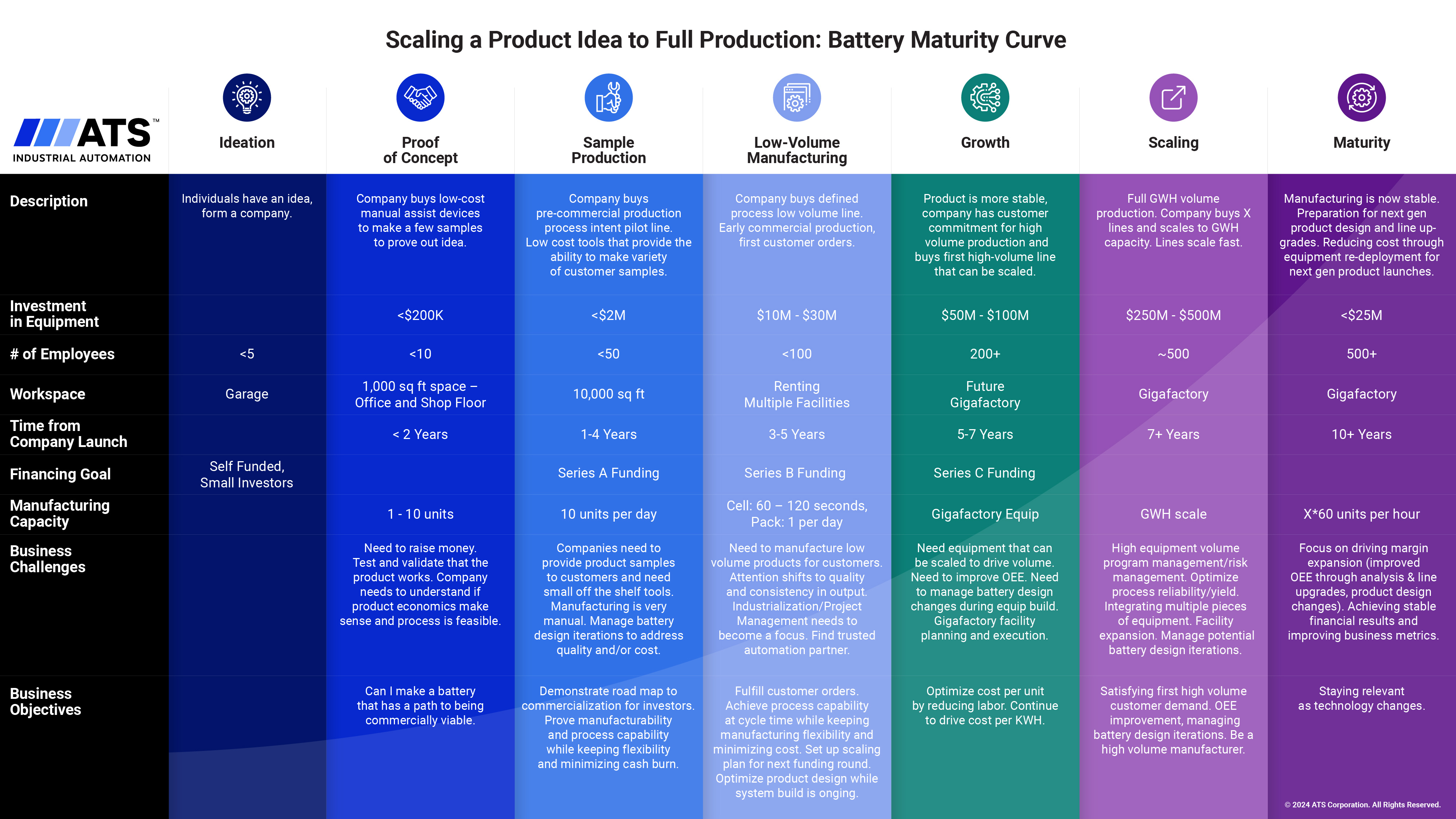

Scaling a Product Idea to Full Production: Battery Maturity Curve

1. Ideation

It all starts with a big idea. While ideas might feel academic or theoretical, they’re the catalyst for change. At this stage, a small group of individuals (usually five or fewer) come together with a key concept and create a company. The team may work out of someone’s garage or borrow office space. Oftentimes, the financial goal is to court small investors or simply self-fund or ‘bootstrap’ the expenses. This approach gives the company’s founders more flexibility in the beginning stages and a strong personal and professional stake in the concept (and success of) their idea.

2. Proof of Concept

Once the idea is viable, it’s time to bring it to life. The founders focus on getting a product that works, which can take more than a year after concept. In addition to being cash-flow sensitive, the small but growing team often isn’t equipped with substantial industrial engineering or manufacturing process know-how. This can limit the breadth of input into product and process design challenges.

The company’s main objective is to solidify process capability and ensure manufacturing flexibility while keeping costs low. Using low-cost manual devices, the company can create limited samples to prove that the concept works, to start seeding interest and recruiting additional investors.

Meanwhile, the company will need to continually design, test, and validate the product with real users to ensure that it functions for various use cases. Engaging an automation partner to discuss plans and feedback on manufacturability can help the company avoid major upfront costs, delayed schedules, or other pitfalls. Sometimes companies will purchase pieces of automation equipment, such as pallet-based conveyor system, presses, dispensing modules, or laser weld cells, in an effort to speed up or assist manual production of samples. Cash management at this phase is critical and expenditures are heavily scrutinized, making options like used, trial or demo equipment helpful considerations.

3. Sample Production

After purchasing a pilot manufacturing line, the company’s primary objective is to support emerging customers with various product samples. By now, the organization is 1-4 years old and operates in a larger workspace, producing several units per day using lean manufacturing.

This is a dynamic time for the company, with evolving designs, fundraising efforts, and a growing customer base. It’s a challenge to manage these demands while reducing costs. Thankfully, customer samples can be produced at a low volume. What’s more, the customer can often conduct their own testing and some rudimentary tooling. While the company’s team is expanding, revenue streams aren’t yet reliable. That means the business will likely be pursuing Series A funding in the millions, depending on the product and the scale ambitions.

Management must also juggle three key priorities: optimize the product, satisfy customers, and keep investors apprised of business progression. A company’s capital expenditure will depend on the product type, technical challenges, and vertical integration. An automation partner can help identify what tools are required and create scalable manufacturing strategies, providing design for manufacturing advice to help minimize costs and meet tight schedules.

4. Low-Volume Manufacturing

With pilot manufacturing equipment in-house, scale planning can finally become a reality. Around the 3-5 year mark, the company may operate in multiple facilities, producing more units per hour. The concept and most process steps are proven, with at least the minimum performance requirements. Material handling and testing are lean and mostly manual—except for the automated assembly line.

With the cost per unit on a downward trajectory, it’s time to focus on the continued production of samples and showing customers that the product can truly be manufactured at speeds and volumes that will satisfy market demand and while allowing the company to achieve profitability. That means investing in customized, low-volume manufacturing equipment.

The company’s biggest challenge is to balance the conflicting goals of managing cash and achieving product and process maturity while meeting critical timelines and growing customer demands. They must also assure investors that they’re on a path to success. Often, customers and investors don’t understand the complexities of stabilizing the manufacturing process. A strong manufacturing automation partner will use engineering tools including digital twin, proof of principle setups and other process development methods to optimize time and process. Software, such as a manufacturing execution system (MES), is used to understand line performance issues. A full solution automation partner is invaluable at this part of the product maturity journey, supporting the path forward for various stakeholders.

5. Growth

Around 5-7 years in, the company’s product is stable. At this stage, the company has installed a high-volume assembly line that produces significant volume. While the investment in equipment may be $20 million or more, and there are fewer than 200 employees, the company leaders look ahead to the next step: becoming a gigafactory.

This is perhaps the most complex phase. The team is confident in its roster of committed customers, product design and processes, and funding to expand the business. But, they’ll need more equipment to drive scale and volume—while optimizing the cost per unit. Leadership needs to consider labor costs, process capability, floor space and location specifications, and product concepts before securing more funding. An automation partner can help the company navigate these growth challenges by collaborating on manufacturing planning, product iteration design support, and capacity expansion through high-volume automation, digital twin deployment, and scale planning solutions.

6. Scaling

The full production factory (or gigafactory) has finally arrived. The company, now 6+ years old, is composed of a large team of around 500. The operation has reached full-volume, high-speed production with an established product, customer base, and financing. Some companies may be producing millions of units per week. Now, the focus is on scaling fast and meeting customer volume commitments.

There are several approaches to scaling, including multiplying capacity by replicating lines and factories in additional regions, or by implementing a new single higher volume automation solution. No matter the approach, the company’s focus is on risk management while also filling the gigafactory with high-volume automation and the talent to run it. Proactive services and spares management offerings can improve facility output and utilization while digital tools like digital twin and digital training can significantly reduce costs and time. What’s more, leaders should ensure their expansion priorities align with current and potential customers’ product design and volume needs.

7. Maturity

In the maturity stage, it’s been perhaps 10 years since the company’s inception, and full-volume production is ongoing. The product has reached maturity, and perhaps the company has as well. Key challenges at this stage mirror those of other multi-hundred-million-dollar facilities. Now, the company is focused on improving overall equipment effectiveness (OEE) in addition to adjusting for the inevitable: evolving product designs and supply chain issues.

How a business responds to ever-changing market challenges, next-gen designs, and technology changes will determine its longevity. Finding a partner that can guide you through these changes and potential line upgrades—especially with digital tools capability—in addition to focusing on meeting ongoing customer needs will set companies apart from the competition.

Every project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Rob Faulhammer

Vice President of Sales, Specialty Automation

ATS Industrial Automation

Rob has helped companies of all kinds to automate and scale production for over 30 years. Rob works with customers throughout their lifecycle to configure services, systems and digital tools strategies to enable product manufacturing at scale.