How We Lead

Innovation, Automation & Digital Transformation

Innovation, Automation & Digital Transformation

Harnessing the power of automation and digital technologies, we help customers solve the unsolvable. Our team of engineers specializes in automation, inspection, testing, high-speed assembly, laser welding, and digital twin technologies.

Adaptable Platform

Our adaptable platform is a modular automation system designed to accelerate deployment timelines, simplify reconfiguration, and support scalable manufacturing automation across industries.

With modular tooling, flexible transport, and plug-and-play controls, this adaptable automation platform is built for speed, scalability, and redeployment.

Digitalization

Unlock the full potential of your manufacturing lines using advanced digital technologies. Visualize, test, and optimize your manufacturing processes before anything is ordered, tooled or produced. Expedite delivery time, enhance production, and ensure your vision is optimized for manufacturing.

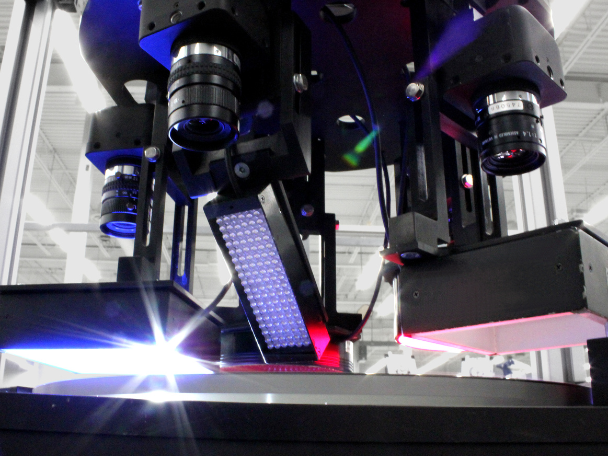

Testing & Validation

Assembly test systems and validation programs are designed to ensure your products perform as expected. With expertise across EV, automotive battery assembly, grid batteries, consumer products, and nuclear tooling, we provide robust, reliable, and customized test automation solutions for your specific applications and industry requirements.

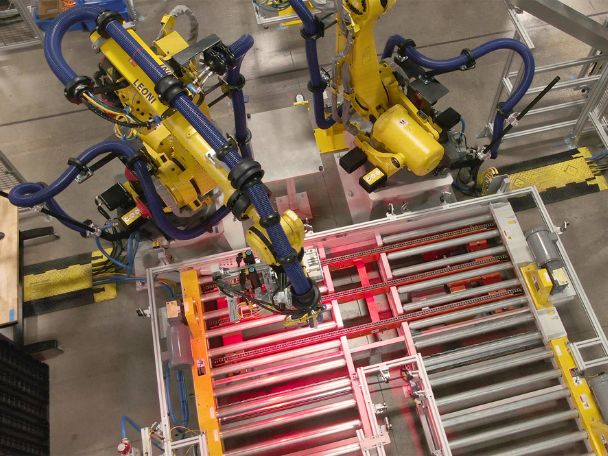

Automation

Delivering automation solutions that drive manufacturing innovations, optimize efficiencies, improve safety, maximize throughput, and ensure quality. We leverage our expertise in automation and digital technologies to help you design and implement a custom automation system to meet your product goals, deliver on time and to budget.

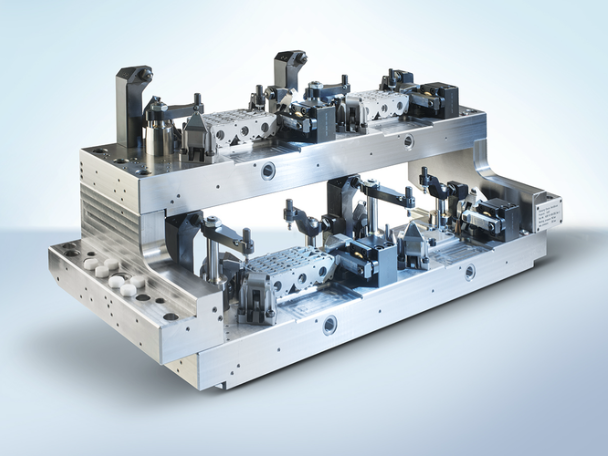

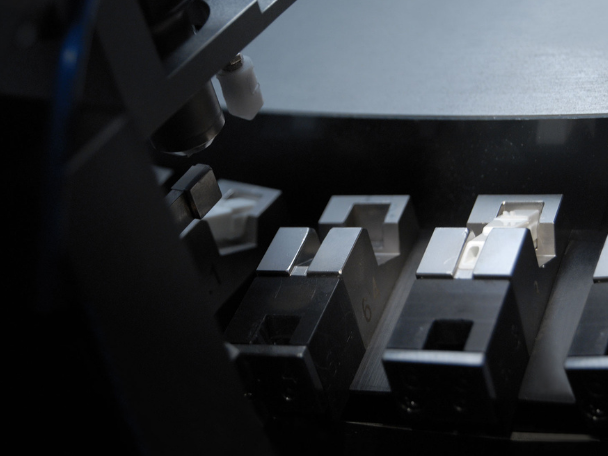

Clamping Fixtures

Specialized manual and hydraulic clamping fixtures for fast, precise machining of components used in tight tolerance, high volume machining operations. Our engineering experts work with customers to customize the clamping fixtures to meet their specific requirements, tolerances, and processes.

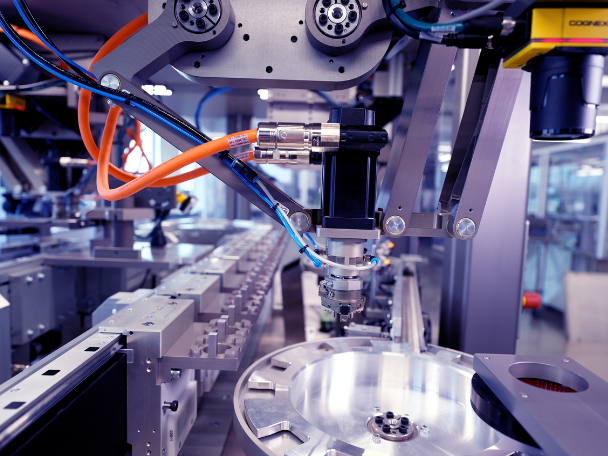

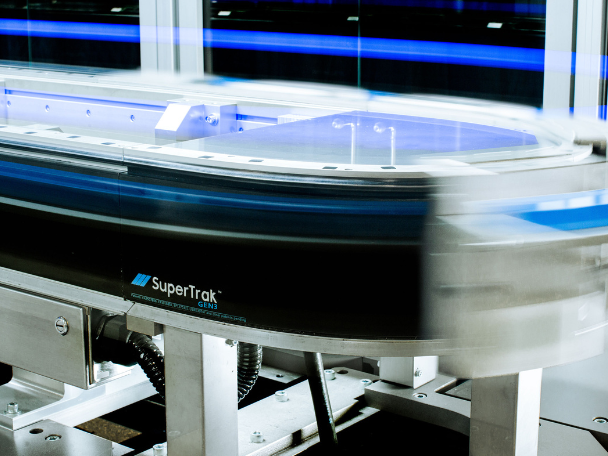

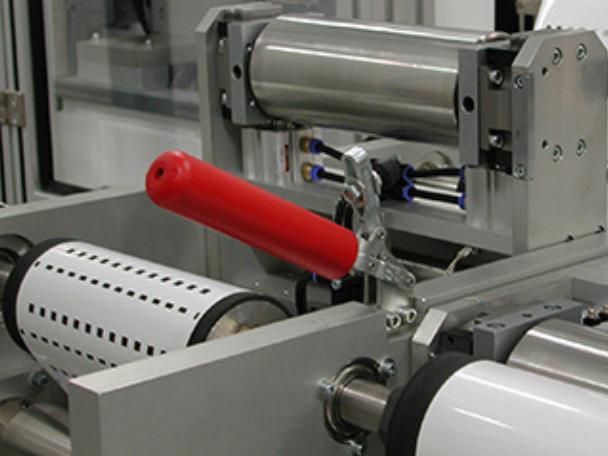

High Speed Assembly

With over 3,000 assembly systems in operation, we are leaders in high-speed assembly. Our configurable, scalable assembly asset platform accommodates one or multiple products for maximal utilization. Discover the benefits of an automated, modular digital assembly platform that can adapt to your requirements while providing speed, precision, and versatility.

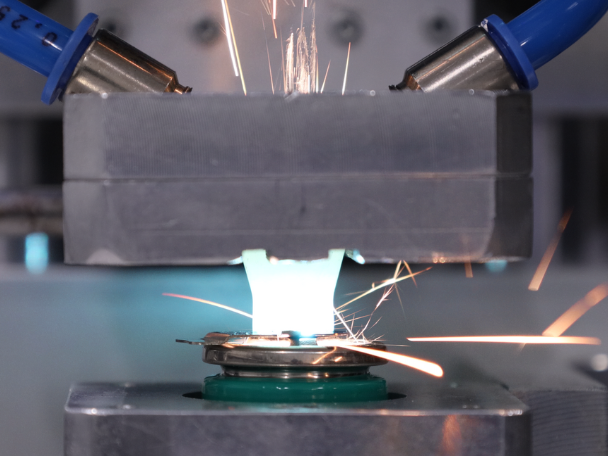

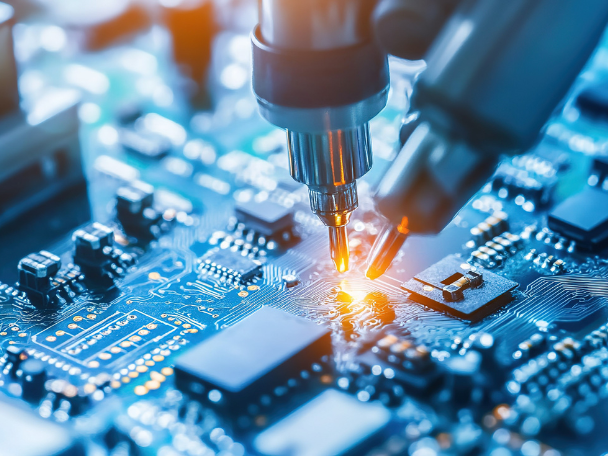

Laser Welding

Precision-based laser welding processes for all stages of battery production. We partner with customers to develop an optimized welding process based on their unique battery designs, metals, and manufacturing needs. Our high-speed, repeatable welding automation system features real-time monitoring that inspects the quality of each weld as it happens.

For Your Consideration…

What if your automation supplier acted like an in-house automation team? We are ready to help you plan for automation capacity and timing, and think through your design for manufacturability. We achieve better outcomes when we work closely together as one team.