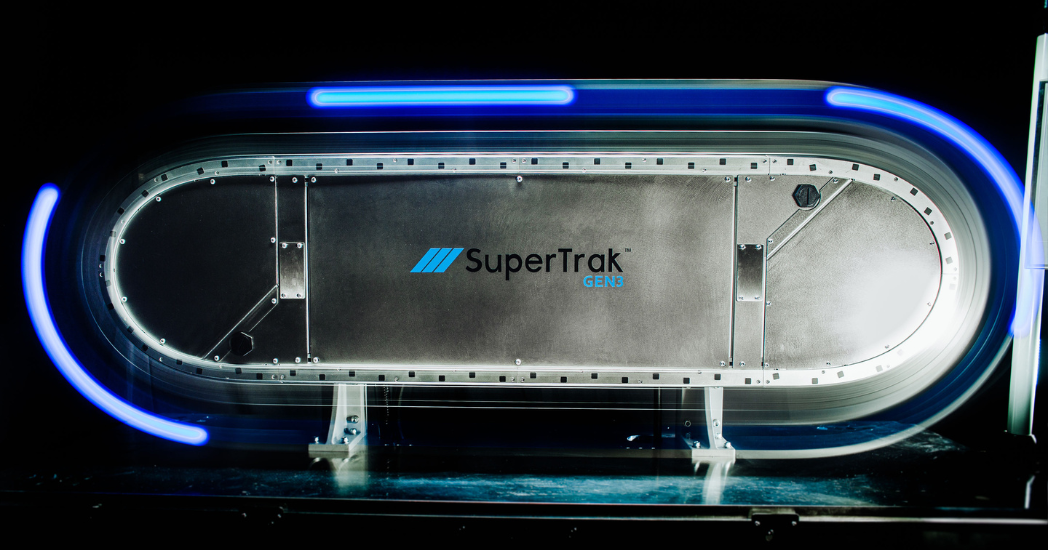

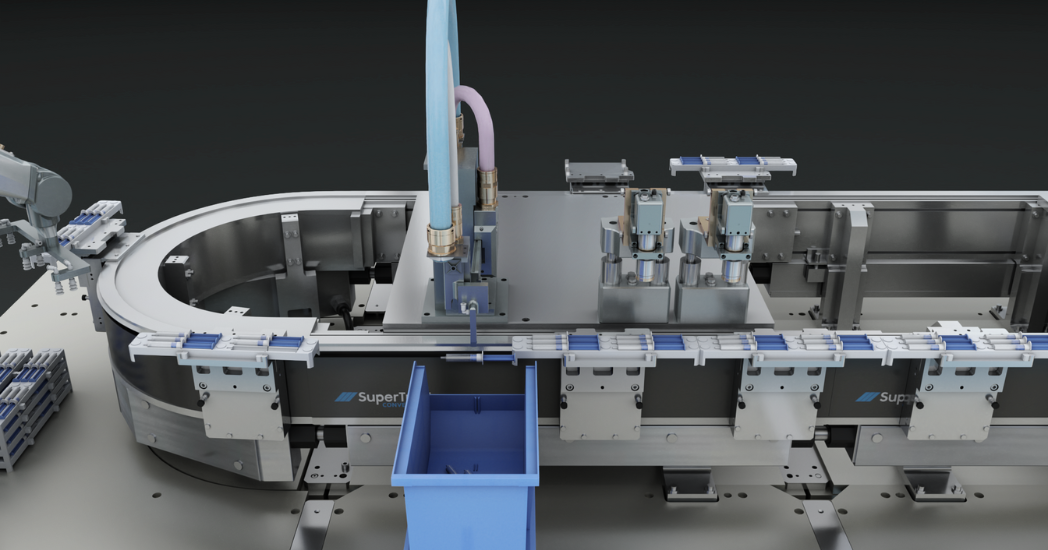

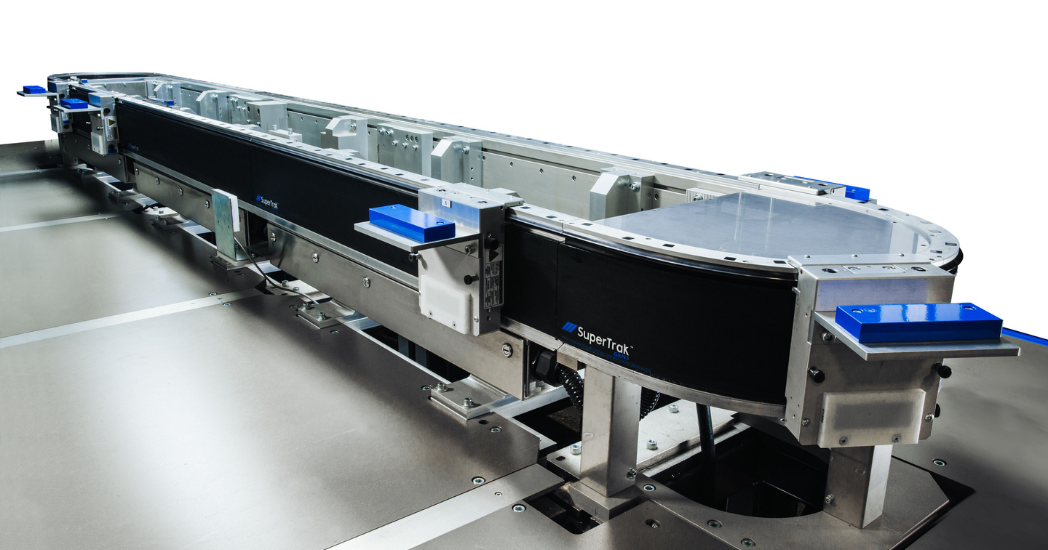

High-speed material handling is critical in modern manufacturing, enabling the efficient and precise movement of components throughout production. ATS Industrial Automation has superior experience leveraging the advanced capabilities of SuperTrak CONVEYANCE™; a Smart Conveyance solution that offers integrated functionality to reduce risk, lower cost, and decrease time to market. Designed to provide high-speed, accurate handling, this modular conveyance platform has the flexibility required to increase productivity and minimize space. The system’s independent shuttle control and modular design allows for easy customization and scalability, ensuring each robust solution is tailored to meet the specific needs of our clients. By utilizing SuperTrak CONVEYANCE™, manufacturers can greatly improve throughput, reduce downtime, and enhance overall operational efficiency.

High Speed Material Handling Challenges

Precision and Accuracy: Maintaining high levels of precision at increased speeds is especially challenging. Ensuring items are handled without errors or misplacements is crucial to maintain product consistency.

System Integration: Installing high-speed material transport systems within existing lines and automation setups can be complex. It requires careful planning and labor time to avoid disruptions.

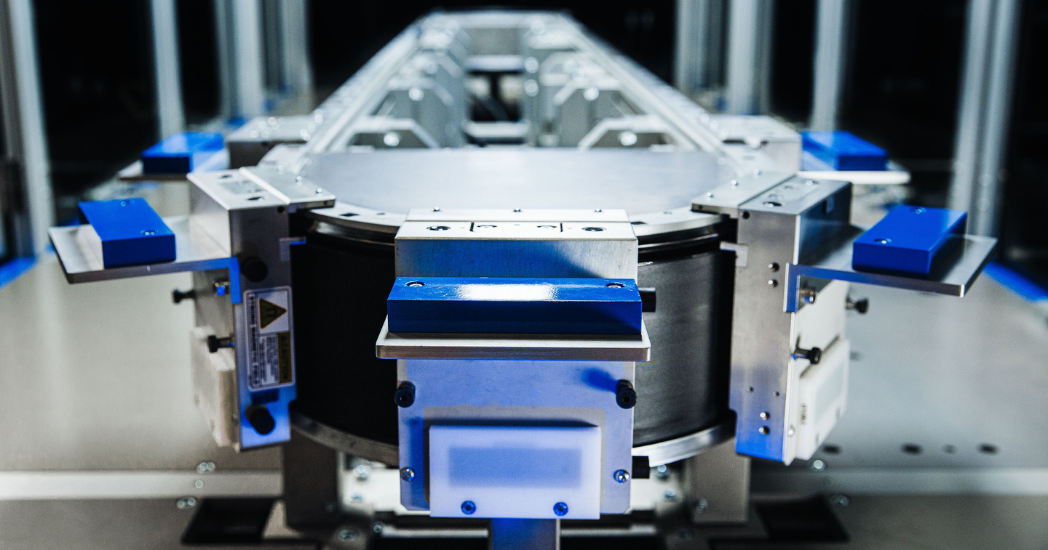

Maintenance and Downtime: Rapid transport platforms often require more frequent upkeep to prevent breakdowns and keep operations going. Minimizing production interruptions during necessary maintenance tasks is critical. SuperTrak have very few moving parts so it’s well suited for low maintenance operation.

Managing Diverse Materials: Original equipment manufacturers (OEMs) often must handle a variety of materials, each characterized by unique properties and requirements. Handling systems must be versatile enough to accommodate these differences, without compromising performance.

Cost Efficiency: Balancing the need for high-speed capabilities with cost-effectiveness is a common concern. OEM leaders must ensure their investment in cutting-edge handling methods will improve productivity and reduce operational expenses.

Space Constraints: Increased throughput goals don’t always equate to an increase in space. Reshoring production while maximizing efficiency of floorspace is paramount.

Features & Benefits

Enhanced Throughput

Faster cycle times and higher accuracy increases throughput, allowing more products to be processed in less time. Product can spend more time in value stations rather than time wasted getting to a process station.

Improved Accuracy

Control over individual shuttle movements ensures correct placement and processing of materials, reducing errors and enhancing the final products.

Scalability and Flexibility

A modular design allows manufacturers to adapt to various production needs, which can be reconfigured as business requirements change.

Reduced Downtime

With fewer moving parts, SuperTrak CONVEYANCE™ experiences minimal downtime, so teams can maximize productivity.

Optimized Floor Space

The system’s streamlined design and integrated functionality maximizes factory layout, reducing the need for additional tooling or stations while reducing costs.

Sustainable Solution

The platform is energy-efficient, minimizing operational costs while optimizing performance. This makes it an environmentally friendly choice for modern manufacturers.

Applications

Battery Manufacturing

High-speed material handling systems are essential in the production of lithium-ion batteries. These platforms enable the rapid, precise transfer of battery cells, including processes such as open-circuit voltage (OCV) testing, laser trimming, tab formation, and cell orientation.

Contact us

Every high-speed material handling project is unique. Allow us to listen to your challenges and share how SuperTrak CONVEYANCE™ can help.