The MultiFlex™ Nuclear Segmentation System is a multi-functional cutting tool specifically designed for nuclear decommissioning and the segmentation of large reactor components with cost and schedule reduction at the forefront.

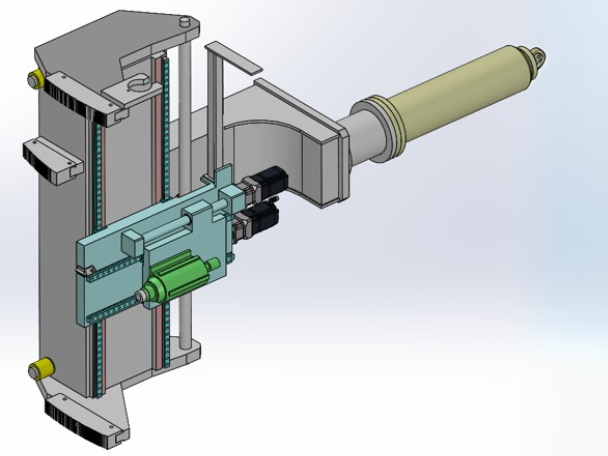

Engineered for robustness and adaptability, the system includes features to reduce vibration, enabling stable cutting operations. The MultiFlex™ nuclear segmentation system incorporates contamination control measures, including a simplified cable management system and minimal contamination traps, facilitating easy decontamination.

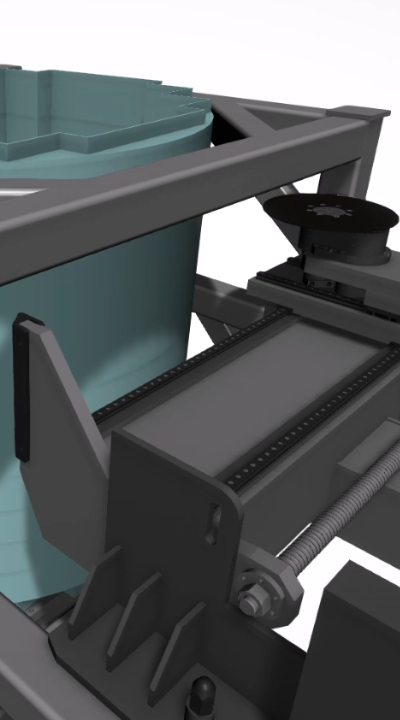

The system is equipped with two electric servo axes, allowing the operator to shift seamlessly between manual jog mode and coordinated moves for more complex and repeatable cuts. The Carriage Axis provides positioning along the main beam, while the Plunge Axis controls the feed. The system’s carriage mounting plate provides a common interface for multiple attachments, such as a compact saw, milling head, and torch, allowing for various cutting, milling, drilling, and thermal applications.

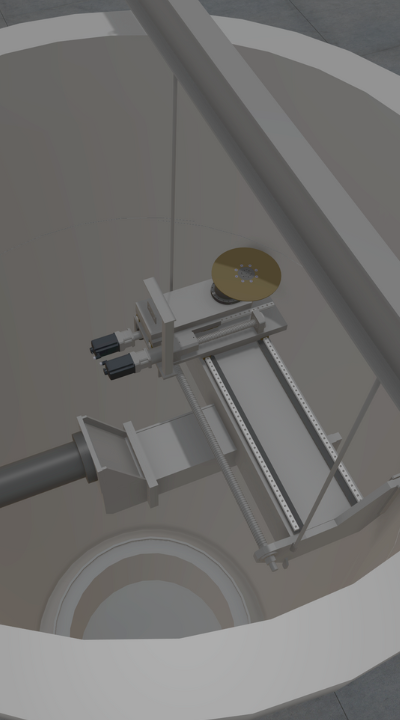

A digital twin, can significantly enhance nuclear decommissioning by providing a virtual replica of the facility for precise cut planning and immersive training. It enables engineers to simulate cutting strategies, optimize waste segregation, and minimize radiation exposure, while also offering workers a risk-free environment to practice complex tasks and emergency responses. This approach improves safety, reduces costs, and ensures efficient collaboration among stakeholders.

Applications

The MultiFlex™ Nuclear Segmentation System has a flexible carriage mounting plate supports multiple attachments, such as a compact saw, milling head, and torch, allowing for various cutting, milling, and thermal applications.

Reactor Component Segmentation

Capable of cutting large components such as reactor pressure vessels, steam generators, and internal structures.

Material Removal & Surface Preparation

The milling head attachment enables the removal of contaminated layers or other unwanted materials.

In-Situ Cutting

The flexible mounting plate and coordinated motion make it effective for operations in tight or complex areas.

Configurations

The MultiFlex™ nuclear segmentation system can be mounted in multiple configurations, allowing the system to perform tasks that have traditionally required multiple pieces of equipment.

Technical Specs

| Weight, Approx | 20,000 lb. /9071 kg. | |

| Main Beam | Robust and stiff strong back with built-in vibration damping. | |

| Plunge Axis | 4.5 tons thrust capacity. | |

| Carriage Axis | 6 tons capacity. | |

| Manual Moves | Full jog mode available to the operator. | |

| Coordinated Moves | Pre-set moves provided for coordinated paths and profiles. | |

| Cable Management System | Catenary design to minimize contamination traps. | |

| Attachment Compatibility | Compact hydraulic saw, milling head, drill, laser head and torch. | |

| Remote Control Station | Provides real-time control and cameras from a safe distance. |

Request a Demo

Every nuclear decommissioning project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.