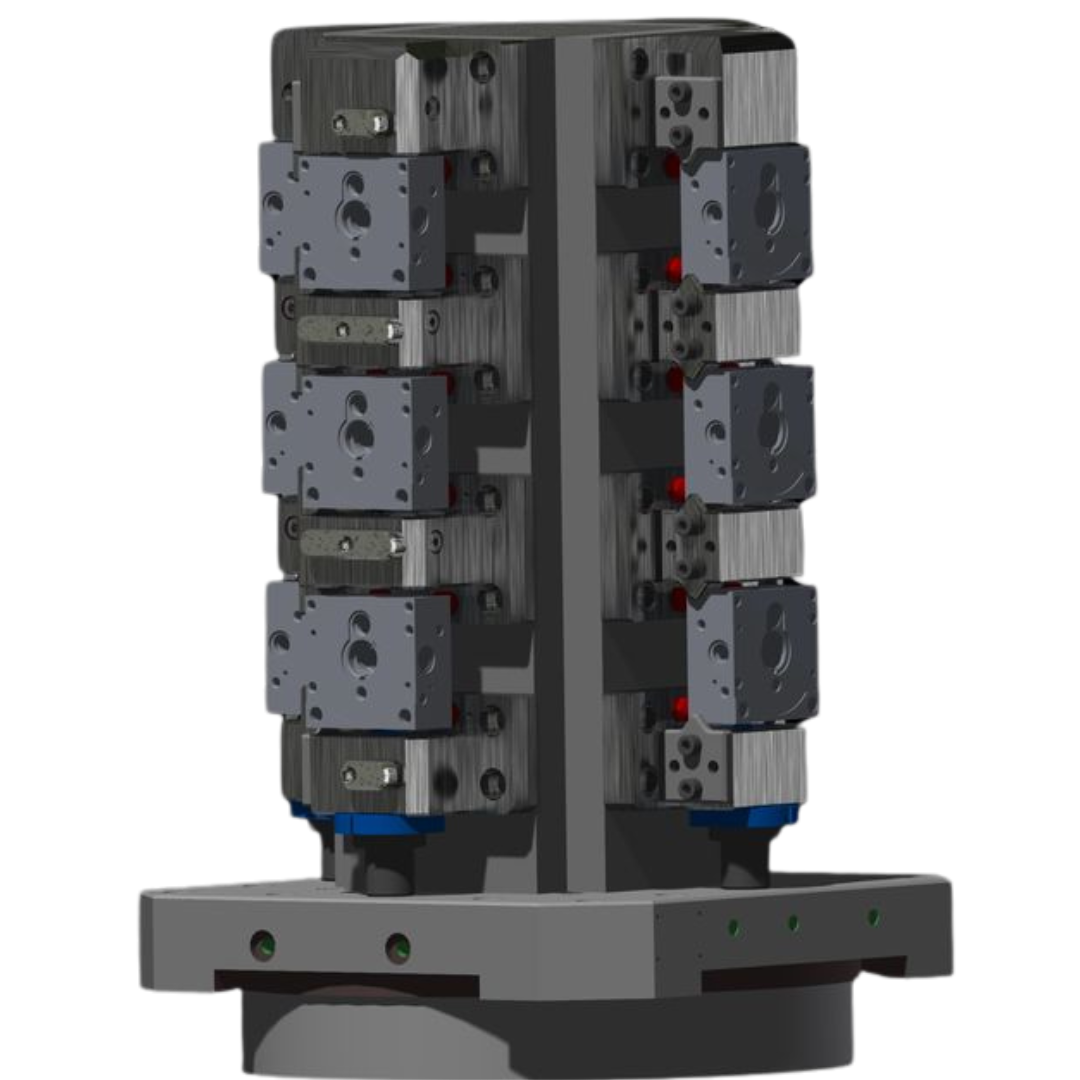

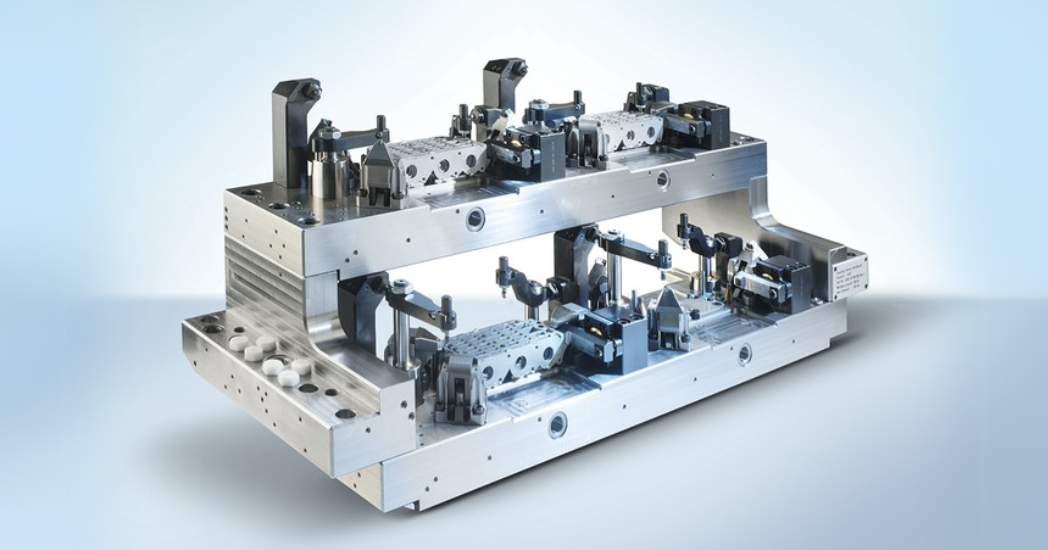

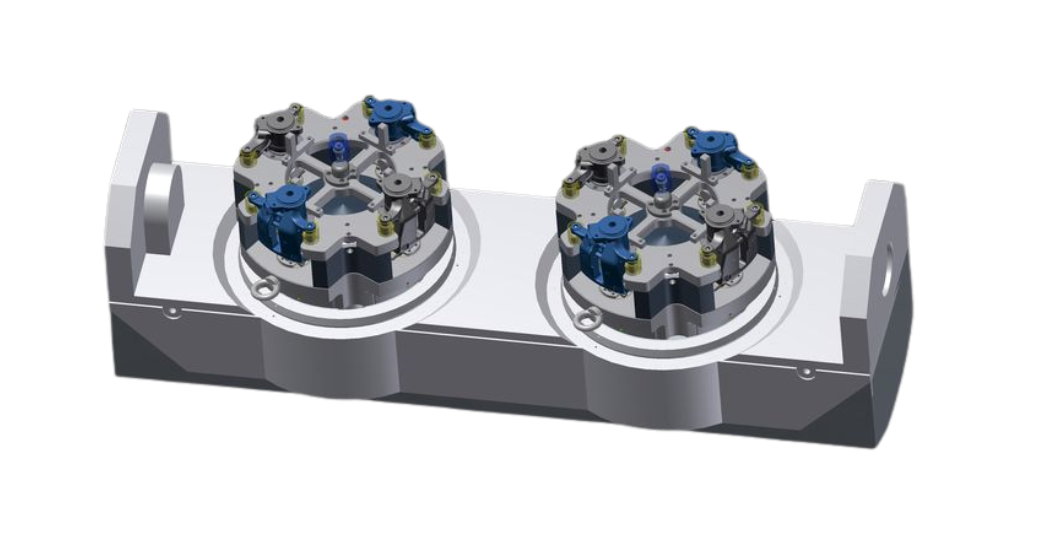

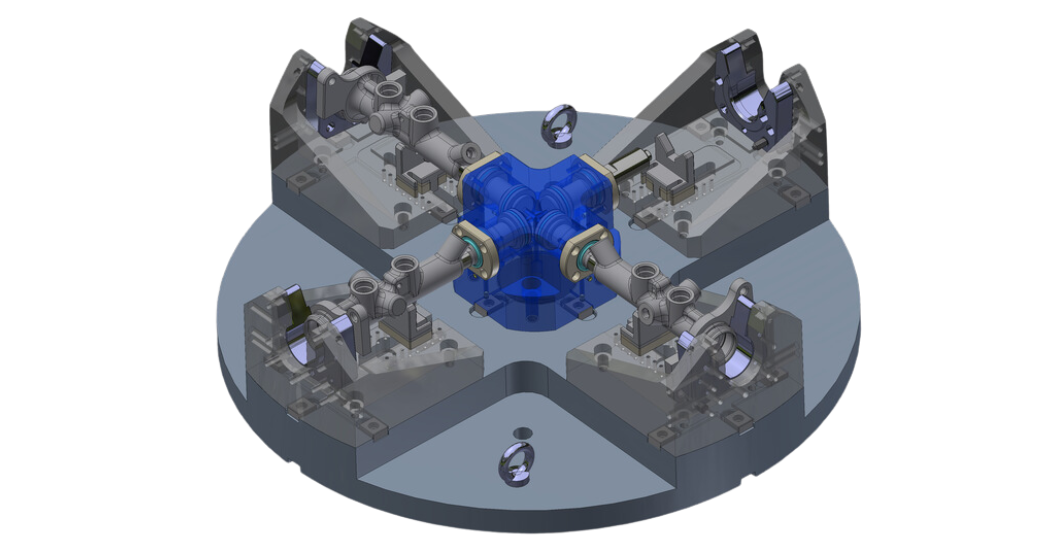

We offer specialized manual and hydraulic clamping fixtures for fast, precise machining of components used in tight tolerance, high volume machining operations. Our engineering experts work with customers to customize the clamping fixtures to meet their specific requirements, tolerances, and processes.

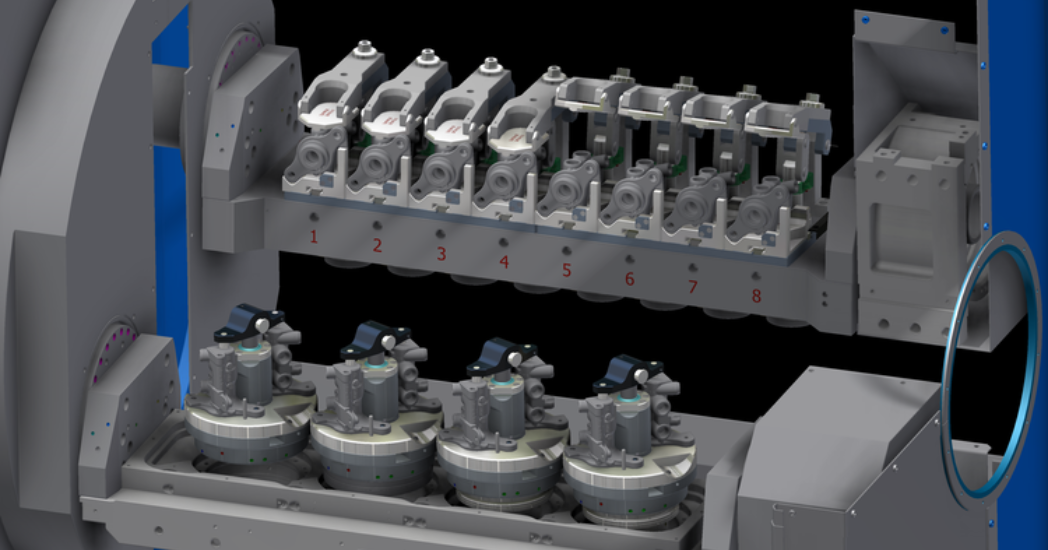

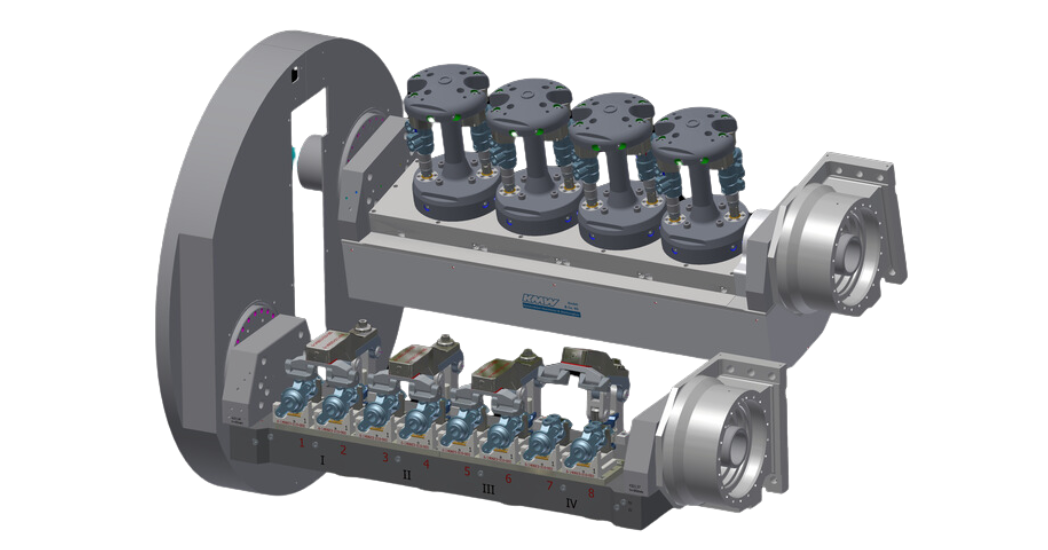

Our clamping fixtures can simultaneously secure multiple components with controlled force, ensuring reliable positioning, accurate cuts, and repeatable results. Our advanced clamping systems provide enhanced OEE, reduced cycle time and make high-volume, high-quality production of machined parts more productive.

Clamping Fixtures Help

Improve dimensional capability on machined surfaces due to non-repeatable part fixturing or movement during machining.

Achieve repeatable results on machined parts while optimizing the machining load-machine-unload sequence through multiple process steps.

Improve machine utilization in high volume operations especially when accounting for changeover between different part types.

Features & Benefits

Our hydraulic clamping systems enable machine shops to optimize their operations while maintaining strict quality control, particularly in high-volume production settings.

Precision & Stability

Parts stay securely in place for precise machining.

Increased Throughput

The fixture simultaneously holds multiple parts, speeding up setup and reducing changeover time.

Repeatability

Ensures consistent clamping of components for repeatable results across batches and over long production periods.

Applications

Our clamping fixture systems are used on a variety of machine types to provide stable, precise positioning and clamping of components during the machining process.

Milling Machines

Keep workpieces firmly fixtured and clamped during milling, cutting, drilling, tapping, slotting, and contouring operations to create complex shapes and details with tight tolerances.

Grinding Machines

For fine, precision grinding, clamps help maintain tight and repeatable tolerances on precise surfaces.

Boring Machines

For deep-hole machining, clamps secure components to prevent movement, delivering consistent depth and alignment.

Contact us

Every manufacturing project is unique. Allow us to listen to your challenges and share how clamping fixtures can help.